Conductive PUA composite emulsion and preparation method thereof

A composite emulsion and formulation technology, applied in the field of conductive PUA composite emulsion and its preparation, to achieve high production efficiency, improve compatibility, and prevent precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

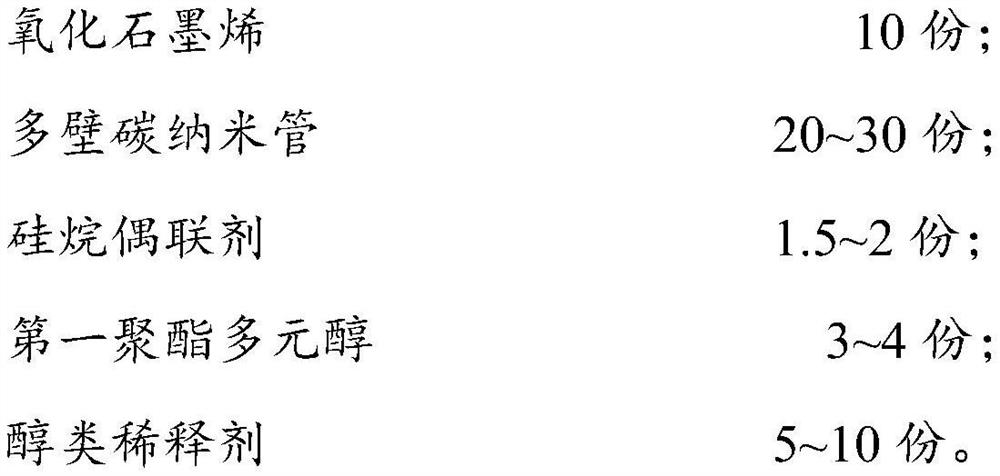

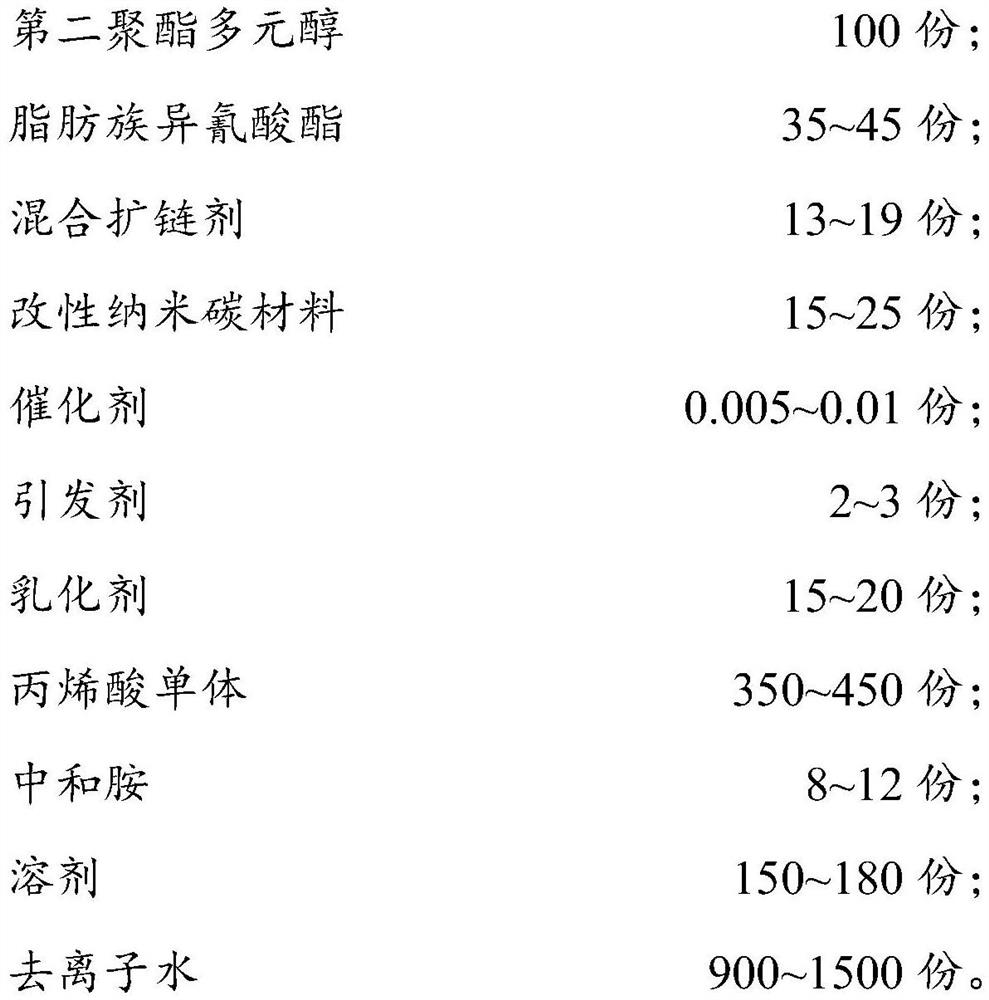

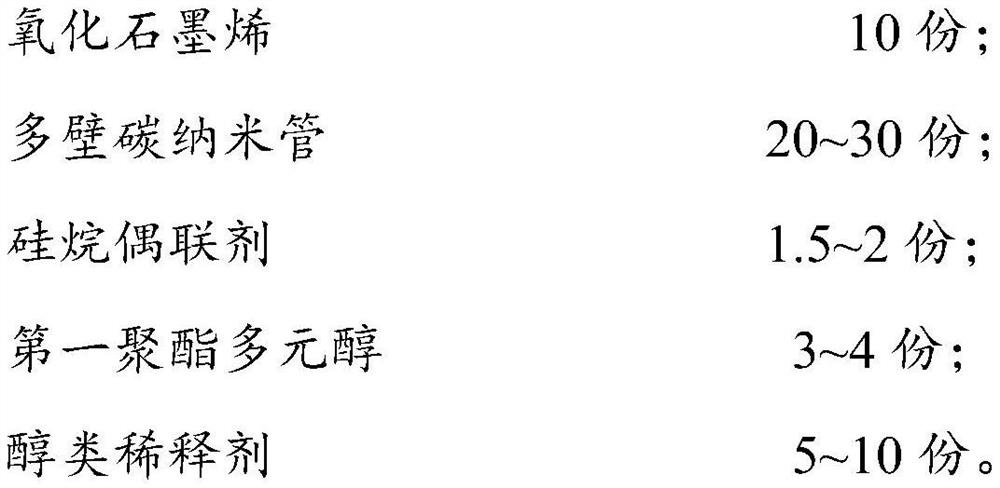

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of conductive PUA composite emulsion, comprising the steps:

[0050](1) add 100 parts of polyethylene adipate diols (molecular weight is 800), 5 parts of 1,4-butanediol and 8 parts of trimethylolpropane in the reaction kettle of nitrogen protection, in Vacuum dehydration at 110°C for 1h, cool down to 70°C, add 50 parts of acetone solvent and stir, turn on the condensing reflux device, rotate at 120 rpm, and take 15 minutes to dissolve the raw materials, then add 15 parts of modified carbon nanomaterials and 0.005 parts of dilaurin Dibutyltin acid catalyst, stirring for 20min to a uniform dispersion state;

[0051] (2) after 40 parts of hexamethylene diisocyanate and 50 parts of acetone solvents are diluted, slowly dropwise into the reaction kettle, the dropwise addition is completed in 20min, be warming up to 85 ℃, stir 50min reaction;

[0052] (3) be cooled to 78 ℃, successively add 1 part of potassium persulfate that the mass concentration is 20%...

Embodiment 2

[0061] A preparation method of conductive PUA composite emulsion, comprising the steps:

[0062] (1) Add 100 parts of polycarbonate diol (molecular weight is 1000), 7 parts of 1,6-hexanediol and 10 parts of dimethylol butyric acid into a nitrogen-protected reaction kettle, and vacuum at 110° C. Dehydrate for 1 hour, cool to 70°C, add 60 parts of acetone solvent and stir, turn on the condensing reflux device, rotate at 120 rpm, and take 15 minutes to dissolve the raw materials, then add 20 parts of modified nano-carbon material and 0.005 parts of dibutyltin dilaurate catalyst , and stir for 25min to a uniform dispersion state;

[0063] (2) after diluting 45 parts of isophorone diisocyanate and 60 parts of acetone solvent, slowly add dropwise in the reaction kettle, finish dropping in 20min, be warming up to 86 ℃, stir 60min reaction;

[0064] (3) be cooled to 79 ℃, add 1 part of potassium persulfate with a mass concentration of 20%, 8 parts of sodium lauryl sulfate successivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com