Decorative plate manufacturing method based on grainy paper veneer

A manufacturing method and technology of wood grain paper, applied in special decorative structures, manufacturing tools, decorative art, etc., can solve problems such as peeling and separation, and achieve the effects of improving bonding strength, prolonging service life, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

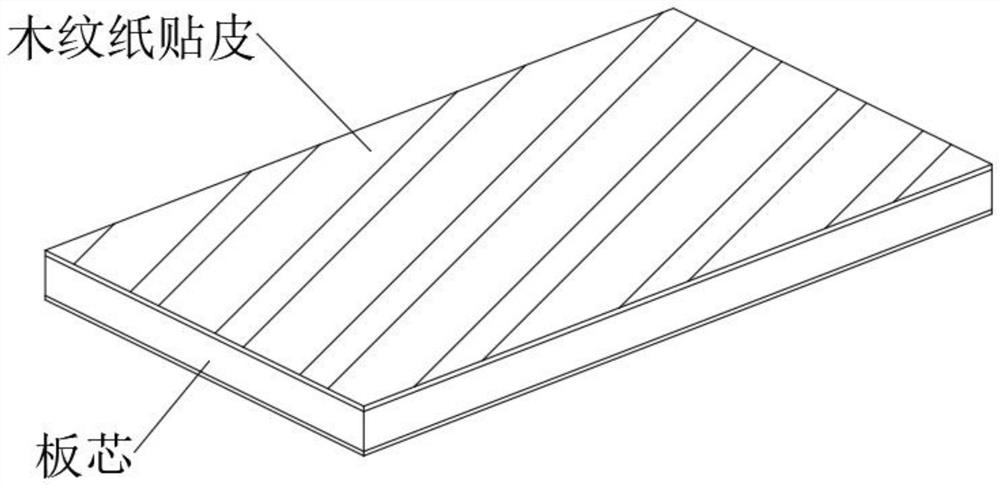

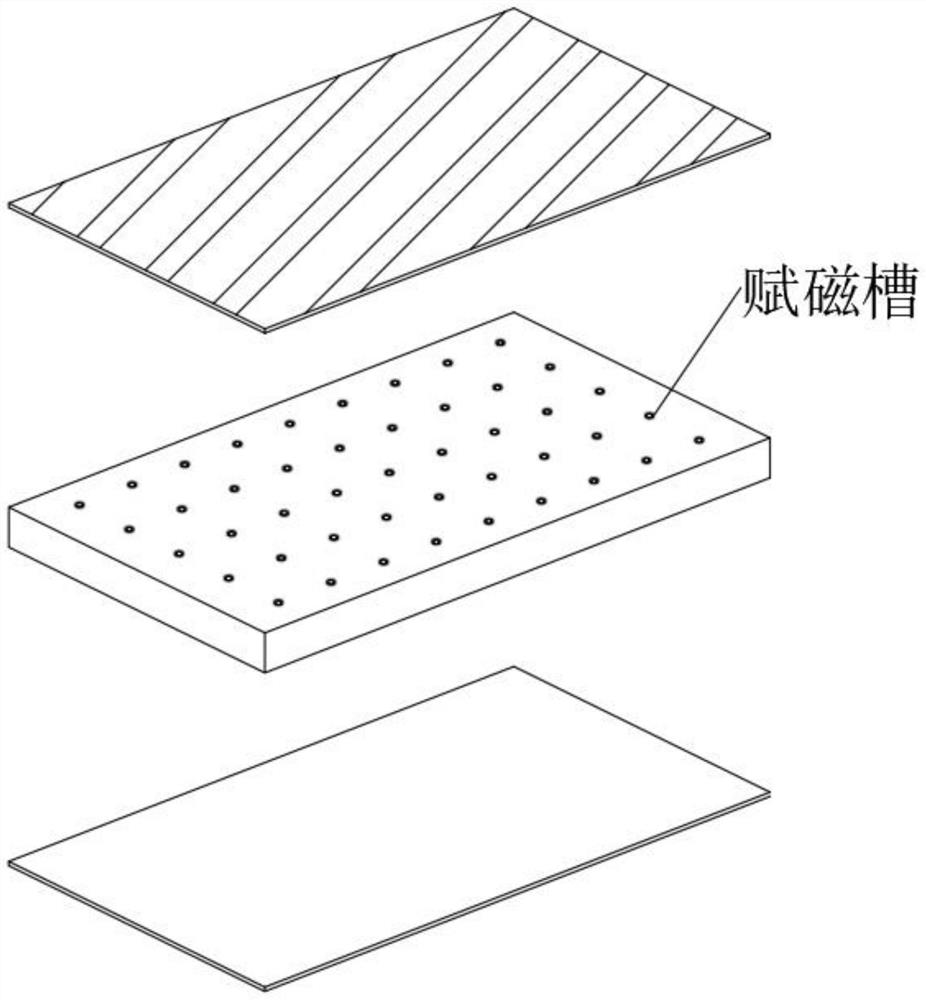

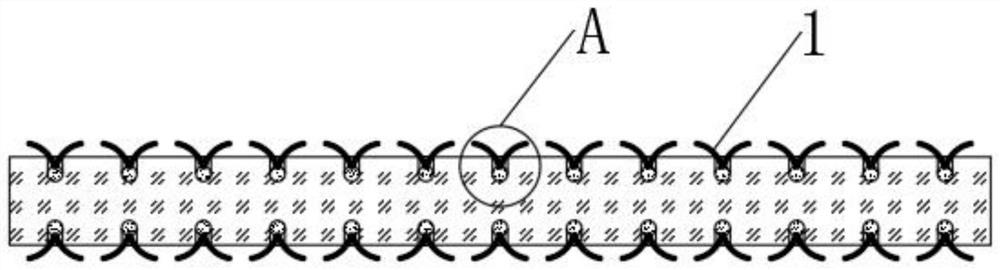

[0045] see Figure 1-3 , a method for manufacturing a decorative board based on wood grain paper veneer, comprising the following steps:

[0046] S1. Prepare magnetic ink and base paper, spread out the base paper and print a layer of magnetic ink on the surface, and dry to form wood grain paper skin;

[0047] S2. Prepare corresponding prefabricated molds, and prefabricate magnetic pendulums for standby use, and open a plurality of evenly distributed magnetic slots on both surfaces of the plate core;

[0048] S3. Insert the magnetizing pendant into the magnetizing slot, coat a layer of adhesive on the surface of the board core, and fill the magnetizing slot;

[0049] S4. Align the back of the wood grain paper to cover the board core, and then hot-press to obtain a blank board;

[0050] S5. Clean up the excess adhesive, check the flatness and bonding degree of the blank, and pack it into storage after passing the test.

[0051] The magnetic ink is an existing product, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com