Spiral nanofiber reinforced composite rubber pad

A composite rubber and nanofiber technology, applied in the field of composite rubber mats, can solve the problems that the reinforcement effect needs to be improved, the helical carbon nanofibers are easy to agglomerate, and it is not easy to combine, etc., so as to shorten the vulcanization rate, improve the mechanical properties, and improve the hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

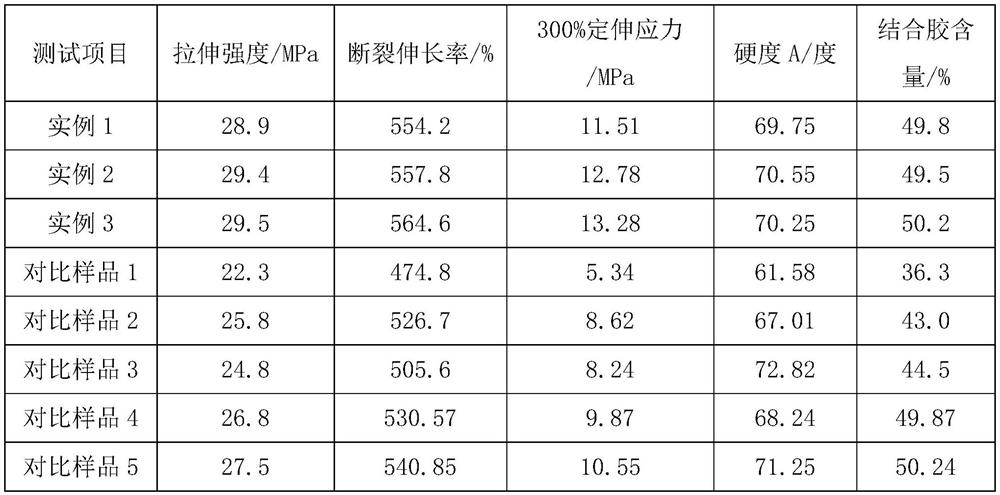

[0034] Embodiment 1 of the present invention provides a composite rubber pad reinforced by helical nanofibers, and specifically provides an application in rubber of a reinforcing material composed of nano-palm fibers, helical nano-carbon fibers and nano-active calcium carbonate. The reinforcing material provided by the invention can not only effectively improve the mechanical properties of the rubber, but also have the effect of shortening the vulcanization rate.

[0035] In the present invention, nano palm fiber, helical nano carbon fiber and nano active calcium carbonate are added to the rubber compounding system in coordination. Nano activated calcium carbonate improves the dispersibility of nano palm fibers and helical carbon nano fibers in the rubber system, so that the nano palm fibers and helical carbon nano fibers can be uniformly dispersed in the rubber matrix. At the same time, the synergy of the three materials is to improve the comprehensive properties of the rubbe...

example 1

[0049] In this example 1, the first rubber layer is composed of the following raw materials by weight: 100 parts of natural rubber, 100 parts of nitrile rubber, 20 parts of composite reinforcing materials, 35 parts of carbon black, 2 parts of stearic acid, oxidized 4 parts of zinc, 1 part of antioxidant, 1 part of accelerator DM, 1 part of accelerator CZ and 2 parts of sulfur. Wherein, the mass ratio of the nano palm fiber, helical nano carbon fiber and nano activated calcium carbonate is 1:1:2.

[0050] The second rubber layer includes the following raw materials in parts by weight: 100 parts of natural rubber, 100 parts of nitrile rubber, 20 parts of composite reinforcing materials, 35 parts of composite fiber materials, 15 parts of carbon black, 2 parts of stearic acid, and 4 parts of zinc oxide. 1 part of antioxidant, 1 part of accelerator DM, 1 part of accelerator CZ and 2 parts of sulfur. Wherein, the composite reinforcing fiber is composed of basalt fiber, glass fiber ...

example 2

[0055] In this example 2, the first rubber layer is composed of the following raw materials by weight: 110 parts of natural rubber, 110 parts of nitrile rubber, 22 parts of composite reinforcing materials, 37 parts of carbon black, 2 parts of stearic acid, oxidized 4 parts of zinc, 1 part of antioxidant, 1 part of accelerator DM, 1 part of accelerator CZ and 2 parts of sulfur. Wherein, the mass ratio of the nano palm fiber, helical nano carbon fiber and nano activated calcium carbonate is 1:1:2.

[0056] The second rubber layer includes the following raw materials in parts by weight: 110 parts of natural rubber, 110 parts of nitrile rubber, 22 parts of composite reinforcing materials, 37 parts of composite fiber materials, 17 parts of carbon black, 2 parts of stearic acid, 4 parts of zinc oxide 1 part of antioxidant, 1 part of accelerator DM, 1 part of accelerator CZ and 2 parts of sulfur. Wherein, the composite reinforcing fiber is composed of basalt fiber, glass fiber and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com