Method for reducing carbon content of boiler fly ash

A fly ash carbon content and boiler technology, which is applied in the preparation of test samples, chemical analysis by combustion, etc., can solve the threat of boiler safety operation, increase the carbon content of boiler fly ash, and increase the heat loss of exhaust gas. and other problems, to achieve good environmental protection and economic benefits, improve the burnout rate of mixed coal, and ensure the effect of safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

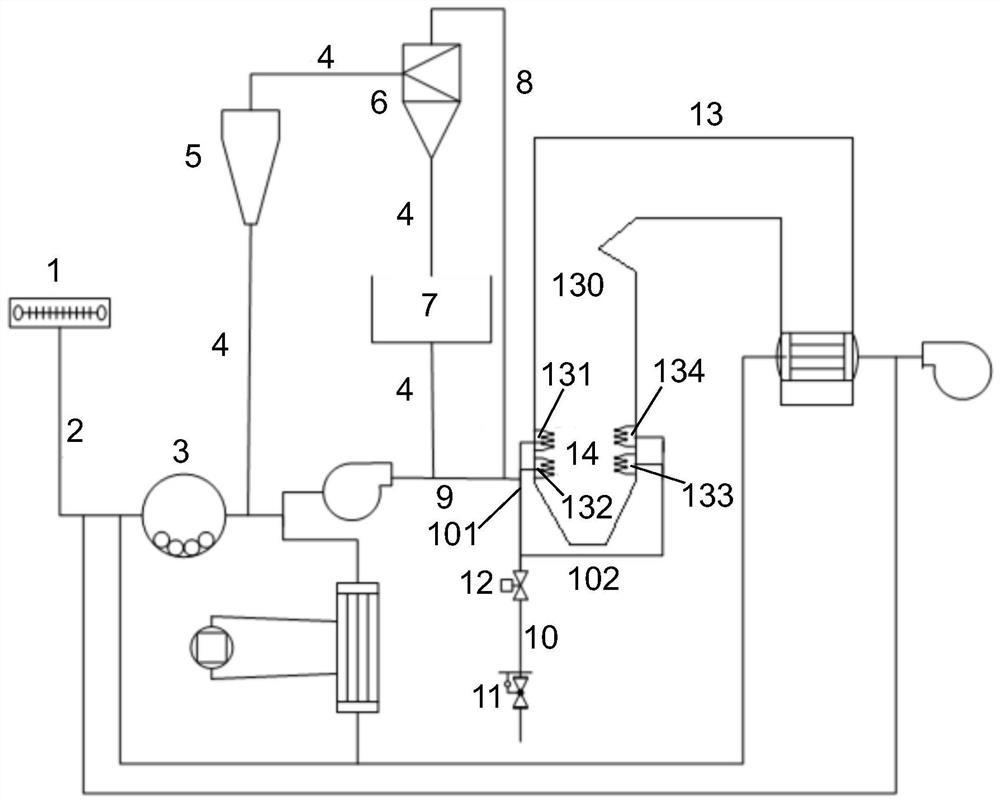

[0042] In the mixed coal used in this embodiment, bituminous coal accounts for 50wt% of the mixed coal. During the combustion process, decompressed oxygen is injected through an automatic adjustment valve according to the oxygen content in the furnace and the shape of the flame, which specifically includes the following steps:

[0043] 1) The mixed coal in the coal feeder is sent to the coal mill through the transportation chain. After being crushed by the coal mill for 18 minutes, it enters the coarse powder separator and the fine powder separator from the outlet of the coal mill through the coal powder pipeline for the first stage. Screening and secondary screening to screen out qualified and unqualified pulverized coal, of which the particle size of unqualified pulverized coal is ≥90 μm, and returned to the coal mill for reprocessing at a rate of 8 to 10 tons / hour; If the particle size is less than 90μm, it will be sent to the pulverized coal silo at a rate of 35-37 tons / hou...

Embodiment 2

[0047] In the mixed coal used in this embodiment, bituminous coal accounts for 51wt% of the mixed coal. During the combustion process, decompressed oxygen is injected through an automatic adjustment valve according to the oxygen content in the furnace and the shape of the flame, which specifically includes the following steps:

[0048] 1) The mixed coal in the coal feeder is sent to the coal mill through the transportation chain. After being crushed by the coal mill for 17 minutes, it enters the coarse powder separator and the fine powder separator from the outlet of the coal mill through the pulverized coal pipeline for the first stage. Screening and secondary screening to screen out qualified and unqualified pulverized coal, of which the particle size of unqualified pulverized coal is ≥90 μm, and returned to the coal mill for reprocessing at a rate of 8 to 10 tons / hour; If the particle size is less than 90μm, it will be sent to the pulverized coal silo at a rate of 35-37 tons...

Embodiment 3

[0052] In the mixed coal used in this embodiment, bituminous coal accounts for 60wt% of the mixed coal. During the combustion process, decompressed oxygen is injected through an automatic adjustment valve according to the oxygen content in the furnace and the shape of the flame, which specifically includes the following steps:

[0053] 1) The mixed coal in the coal feeder is sent to the coal mill through the transportation chain. After being crushed by the coal mill for 15 minutes, it enters the coarse powder separator and the fine powder separator from the outlet of the coal mill through the coal powder pipeline for the first stage. Screening and secondary screening to screen out qualified and unqualified pulverized coal, of which the particle size of unqualified pulverized coal is ≥90 μm, and returned to the coal mill for reprocessing at a rate of 8 to 10 tons / hour; If the particle size is less than 90μm, it will be sent to the pulverized coal silo at a rate of 35-37 tons / hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com