Prepn process and apparatus of polyurethane fiber

A polyurethane fiber and prepolymer technology, applied in the direction of single-component polyurethane artificial filament, etc., can solve the problems of increasing cost, process time, and difficulty in realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

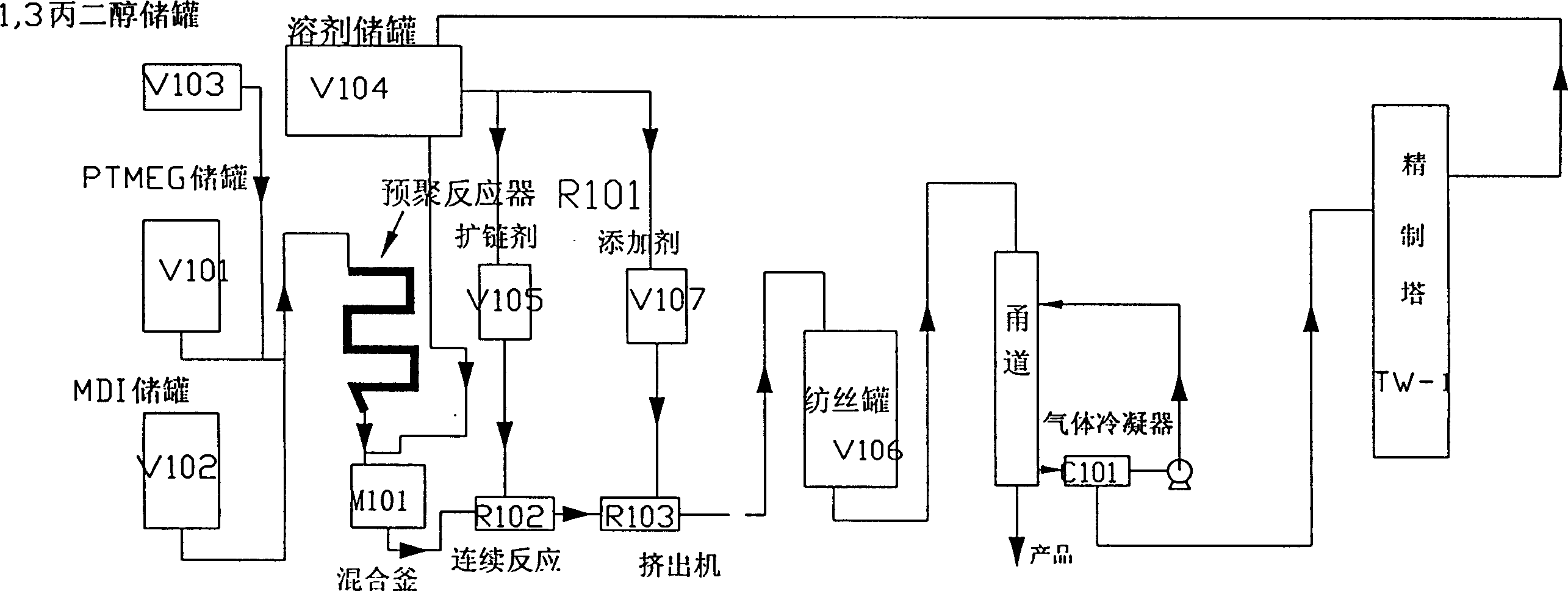

Image

Examples

experiment example 1

[0076] In the experiment of experimental device A, 5.1kg of PTMEG, 0.9kg of MDI, and 0.01kg of 1,3 propylene glycol were mixed evenly, and then 6kg was put into the tubular prepolymerization reactor R101, mixed, the reaction temperature was 70°C, and the reaction was carried out for 120 minutes to generate prepolymerization. The polymer was cooled to 42°C when it was discharged from the reactor, and the process took 175 minutes; the prepolymer was placed in N 2 In the protected container, add 9.0kg DMAC, enter the continuous polymerization reactor with 15kg after stirring evenly. Prepare 0.139kg of mixed diamine composed of ethylenediamine, diethylamine and propylenediamine in a volume ratio of 70:10:20, and add 3.75kg of DMAC. Add 3.889kg of this mixed solution into the polymerization reactor at the same time as the prepolymer solution. Cooling water at 5°C is passed through the jacket of the reactor to maintain the temperature at about 20°C during the reaction. After reacti...

experiment example 2

[0081] The experiment was carried out in the experimental device B, with PTMEG40.8kg, MDI7.2kg, 1,3 propylene glycol 0.08kg mixed evenly. The reaction temperature is 70°C, the reaction time is 120min, and a prepolymer is generated, and the prepolymer discharged from the prepolymerization reactor is placed in N 2 In the protected container, it takes 245 minutes to cool the prepolymer to 40-45°C by passing water at 5°C. Add 73.2kg of DMF, stir evenly and enter the continuous polymerization reactor with 122.08kg. Prepare 1.096g of ethylenediamine, diethylamine, and propylenediamine in a volume ratio of 70:10:20, and add 32.99kg of DMF. Add 152.75 kg of this mixed solution to the polymerization reactor simultaneously with the prepolymer solution. Cooling water at 5° C. is passed through the jacket of the reactor to maintain the temperature at about 20° C. during the reaction. After reacting for one hour, 152.75 kg of the reaction solution entered the screw mixer, and at the same...

experiment example 3

[0088] In the experiment of experimental device A, 5.1kg of PTMEG, 0.9kg of MDI, and 0.01kg of n-butanol were mixed uniformly and then 6kg was put into the tubular prepolymerization reactor R101. The total time of the process was 182min. Add 4.91kg of pyrrolidone, stir evenly and enter the continuous polymerization reactor with 10.9kg. Configure ethylenediamine, diethylamine, propylenediamine 0.14kg altogether, its volume ratio is 70:10:20, add 2.41kg pyrrolidone. Add 2.56kg of this mixed fiber solution and the prepolymer solution into the polymerization reactor at the same time. Cooling water at 5°C is passed through the jacket of the reactor to maintain the temperature at about 20°C during the reaction. After reacting for one hour, 13.47 kg of the reaction solution entered the screw mixer, and 60 g of LD622 antioxidant (ciba company product) was added at the same time, and 43.45 g of solvent was added, and the mixed solution entered the spinning system.

[0089] The amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com