Textile defect type identification method based on artificial intelligence

A defect type, artificial intelligence technology, applied in the field of textiles, can solve the problems of low recognition efficiency, dependence on recognition effect, high false detection rate and missed detection rate, and achieve the effect of high recognition accuracy, fast detection speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

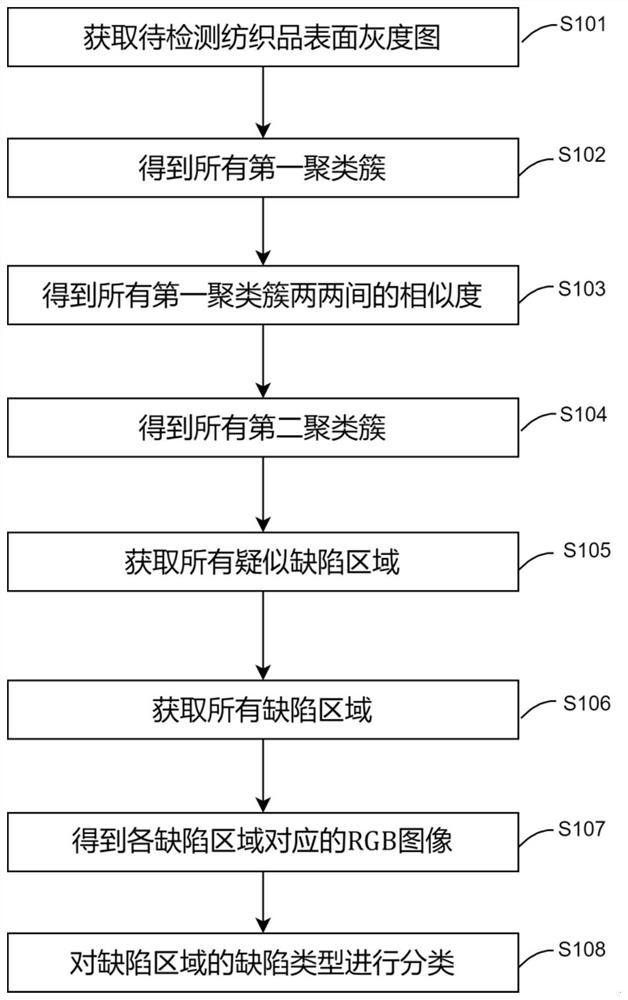

[0057] The embodiment of the present invention provides an artificial intelligence-based textile defect type identification method, such as figure 1 shown, including:

[0058] S101. Obtain a grayscale image of the surface of the textile to be detected.

[0059] Among them, grayscale image, also known as grayscale image. The relationship between white and black is divided into several levels according to the logarithmic relationship, which is called grayscale. Grayscale is divided into 256 levels.

[0060] S102. Perform clustering processing on the grayscale image to obtain all the first clusters.

[0061] Among them, the process of dividing a collection of physical or abstract objects into multiple classes consisting of similar objects is called clustering.

[0062] S103: Perform Gaussian fitting according to the gray value of each pixel in each first cluster, calculate the KL divergence between the Gaussian models corresponding to each first cluster, and obtain all the fi...

Embodiment 2

[0077] The invention mainly detects and classifies the defects on the surface of the textiles by means of artificial intelligence, and further identifies the types of defects of the textiles by performing feature extraction on the image data to identify the defects of the detection surface and other conditions. The method of the invention can realize the detection of defects on the surface of textiles and classify and identify the defect types, so as to provide specific defect categories for textile workers, so that the workers can take corresponding repair measures for different defect types.

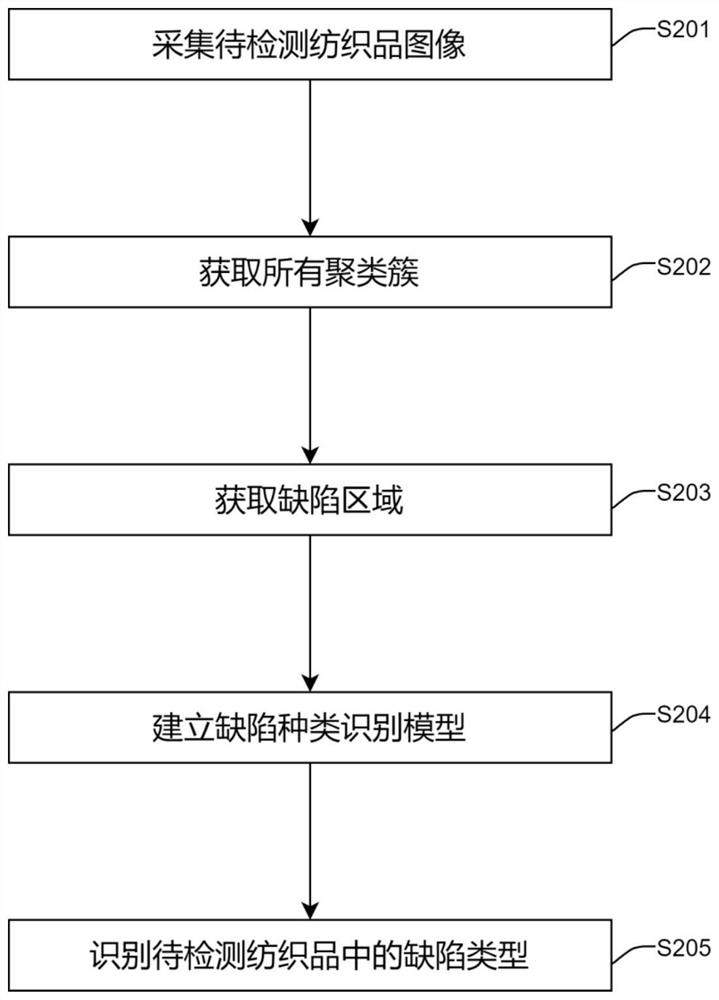

[0078] The embodiment of the present invention provides an artificial intelligence-based textile defect type identification method, such as figure 2 shown, including:

[0079] S201. Collect an image of the textile to be detected.

[0080] First, a device is deployed just above the textile to collect images, and the camera's shooting range and angle are adjusted by the implementer acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com