Mining stone crusher operation system

An operating system and rock crusher technology, applied in grain processing and other directions, can solve problems such as low operating efficiency, high labor costs, and shortage of workers, and achieve the goal of improving precision and accuracy, saving labor costs, and improving operating accuracy and speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

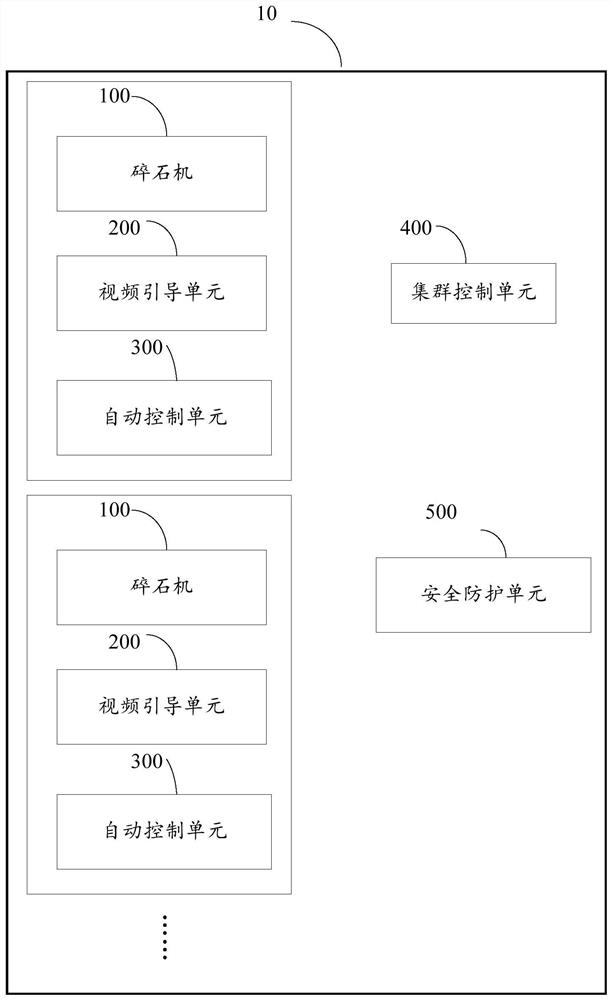

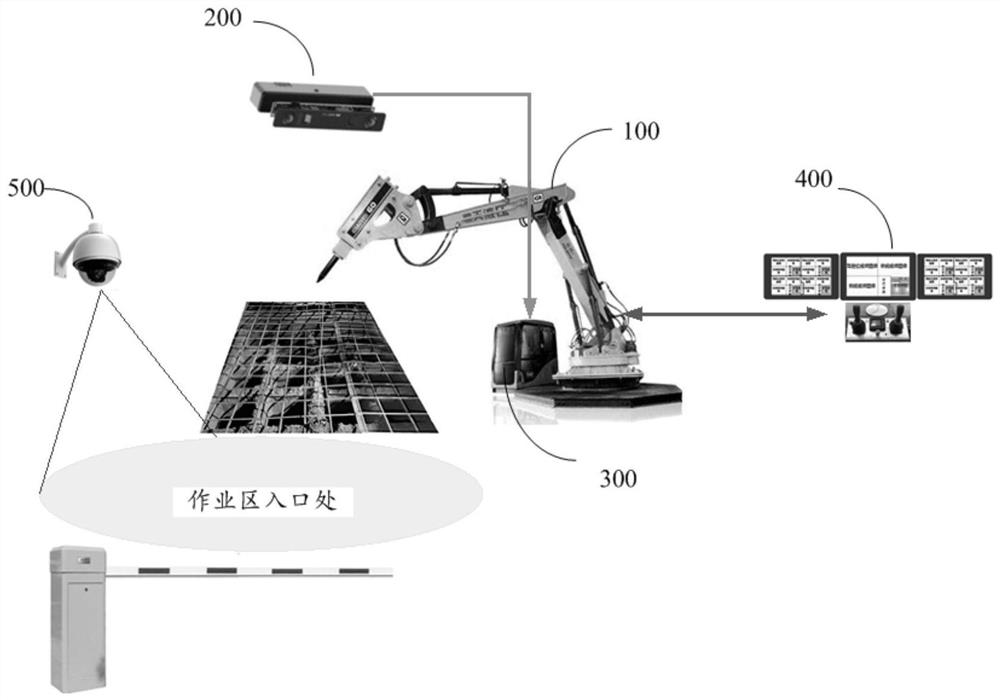

[0029] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

[0030] It should be noted that like numerals and letters denote similar items in the following figures, therefore, once an item is defined in one figure, it does not require further definition and explanation in subsequent figures. Meanwhile, in the description of the present application, the terms "first", "second" and the like are only used to distinguish descriptions, and cannot be understood as indicating or implying relative importance.

[0031] Some mines at home and abroad have introduced remote control systems for fixed rock crushers. With the support of remote remote control systems for fixed rock crushers, operators can be located in the ground control center, connect to the control system of on-site equipment through the remote communication network, and use on-site installation The camer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com