Production process for refractory ceramic plate

A technology for refractory ceramics and production technology, applied in the field of production technology of refractory ceramic plates, can solve the problems of increased workload of workers, easy omissions in the coating process, affecting the smooth demoulding treatment of ceramic plates, etc., so as to ensure the demoulding treatment, improve effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

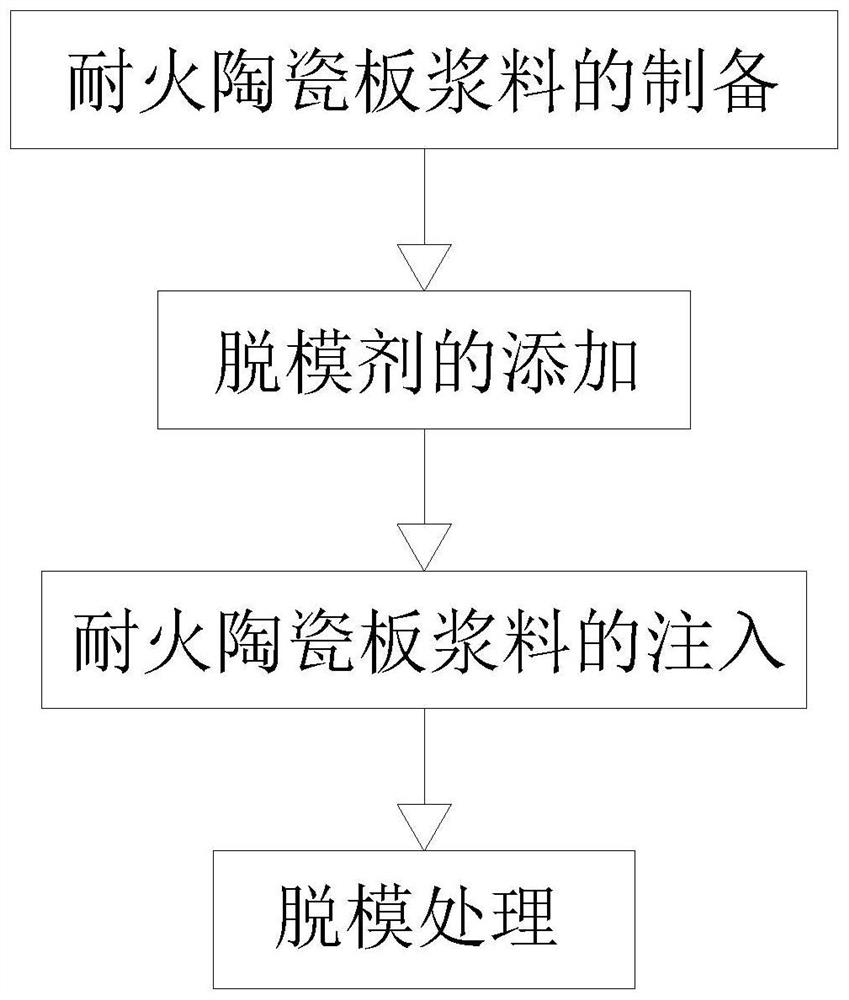

[0044] like Figure 1-10 As shown, the present invention provides a production process for a refractory ceramic plate, the production process for the refractory ceramic plate comprises the following steps:

[0045] Step 1. Preparation of refractory ceramic board slurry. The refractory ceramic board slurry includes the following raw material components in parts by weight: 30-45 parts of kaolin, 28-35 parts of bentonite, 18-25 parts of zircon sand, 15-25 parts of china stone 18 parts, 12-16 parts of sodalite, 8-10 parts of iron oxide and 5-8 parts of alumina, specifically:

[0046] Step A1, adding the raw materials of the refractory ceramic plate slurry to the ball mill in proportion to carry out wet ball milling, the water injection amount in the ball milling process is 12%, the ball milling time is set to 60min, and the blank slurry is obtained after the ball milling is completed;

[0047] Step A2, adding the blank slurry into the high-temperature mixing furnace, controlling ...

Embodiment 2

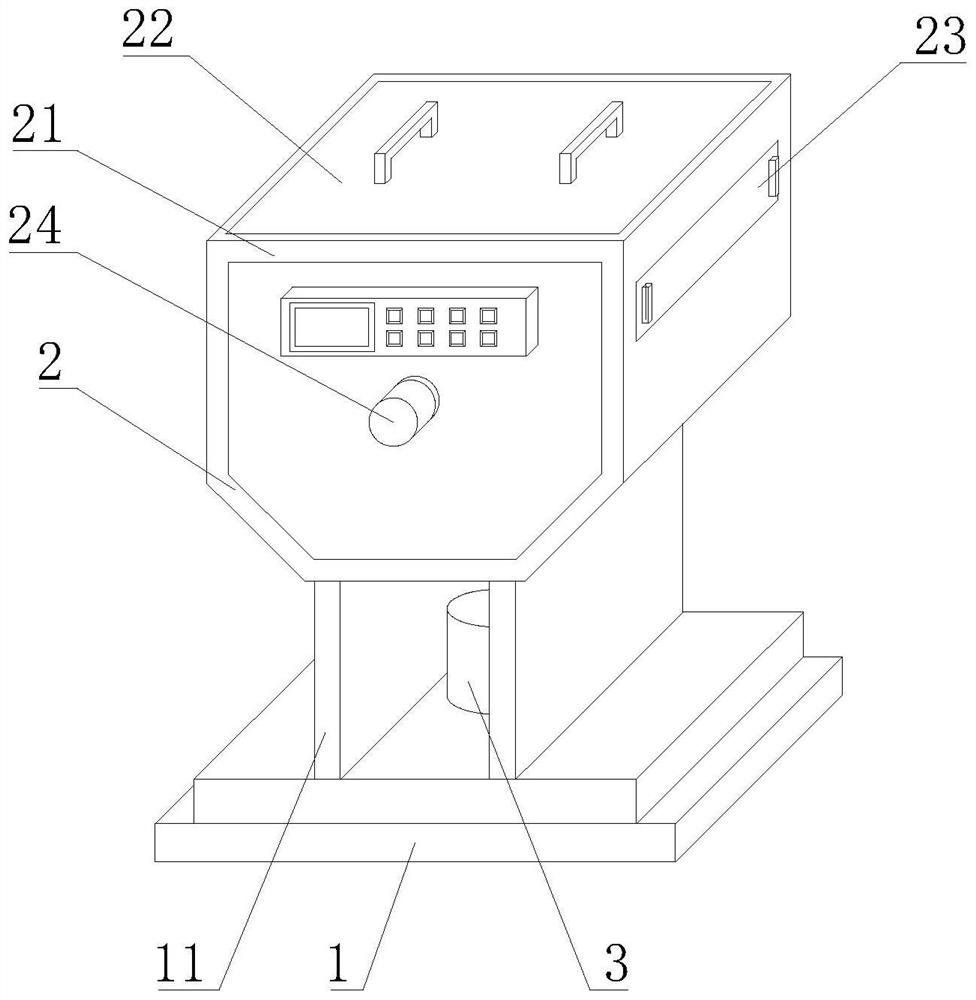

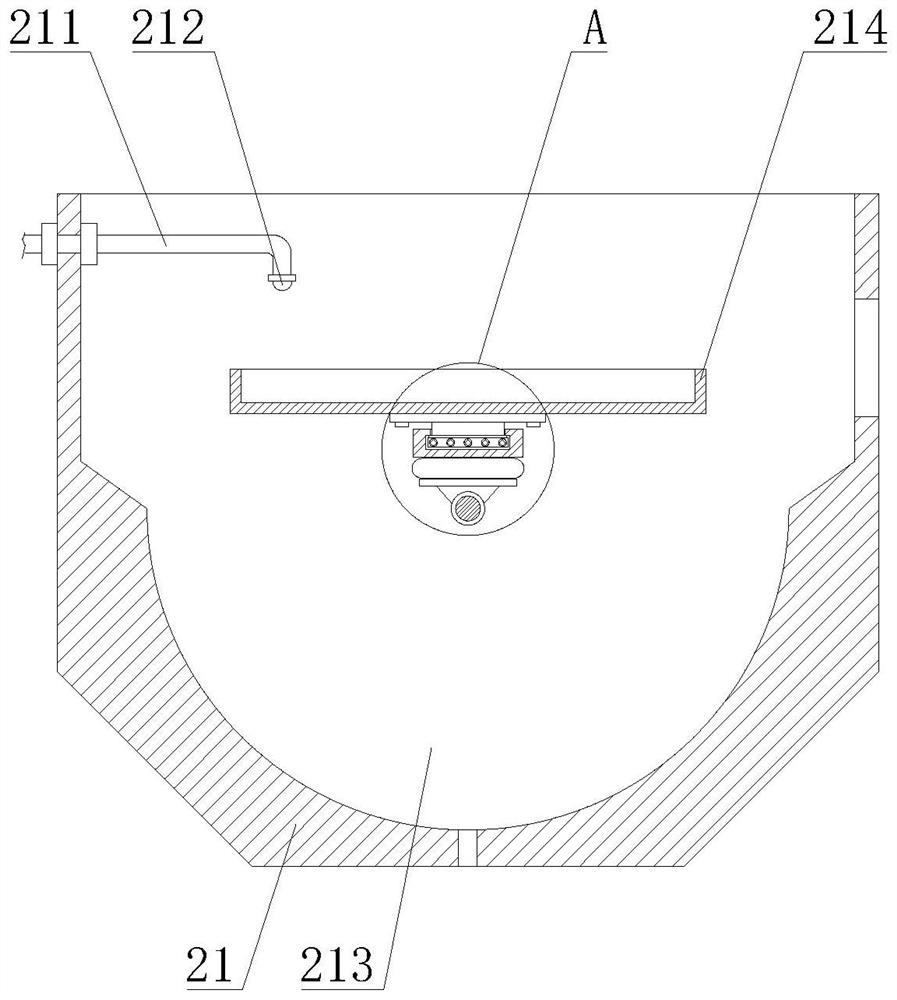

[0052] like Figure 1-10 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the release agent adding device includes a counterweight base 1, and a support frame 11 is fixedly installed on the top of the counterweight base 1, and the support frame 11 is The top is provided with a submerged mold release agent adding mechanism 2, and the top of the counterweight base 1 is provided with a mold release agent recovery mechanism 3. The submerged mold release agent adding mechanism 2 includes a processing frame 21 and a refractory ceramic plate mold body 214. The processing frame 21 It is fixedly installed on the top of the support frame 11, the top of the processing frame 21 is detachably connected with the top cover 22, the right side of the processing frame 21 is detachably connected with the side cover 23, and the front of the processing frame 21 is fixedly installed with a stepper motor 24. A feeding elbow 211 is fixedly insta...

Embodiment 3

[0054] like Figure 1-10 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the release agent recovery mechanism 3 includes a dilution storage tank 31, a communication pipe 32 and an electric telescopic rod 322, and the dilution storage tank 31 is fixedly installed in the The bottom of the inner cavity of the counterweight base 1, the communication pipe 32 is fixedly connected to the bottom of the processing frame 21, the bottom of the communication pipe 32 is fixedly connected to the top of the dilution storage tank 31, the electric telescopic rod 322 is fixedly installed at the bottom of the processing frame 21, and the communication A filter tube 321 is movably connected to the middle of the tube 32 , the moving end of the electric telescopic rod 322 is fixedly connected to the right outer wall of the filter tube 321 , the top of the dilution storage tank 31 is detachably connected with a filter residue receiving box 323 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com