Demolding unit and demolding method

A demoulding and unit technology, applied in the direction of mold handling equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of heavy quality, low production efficiency, and many specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

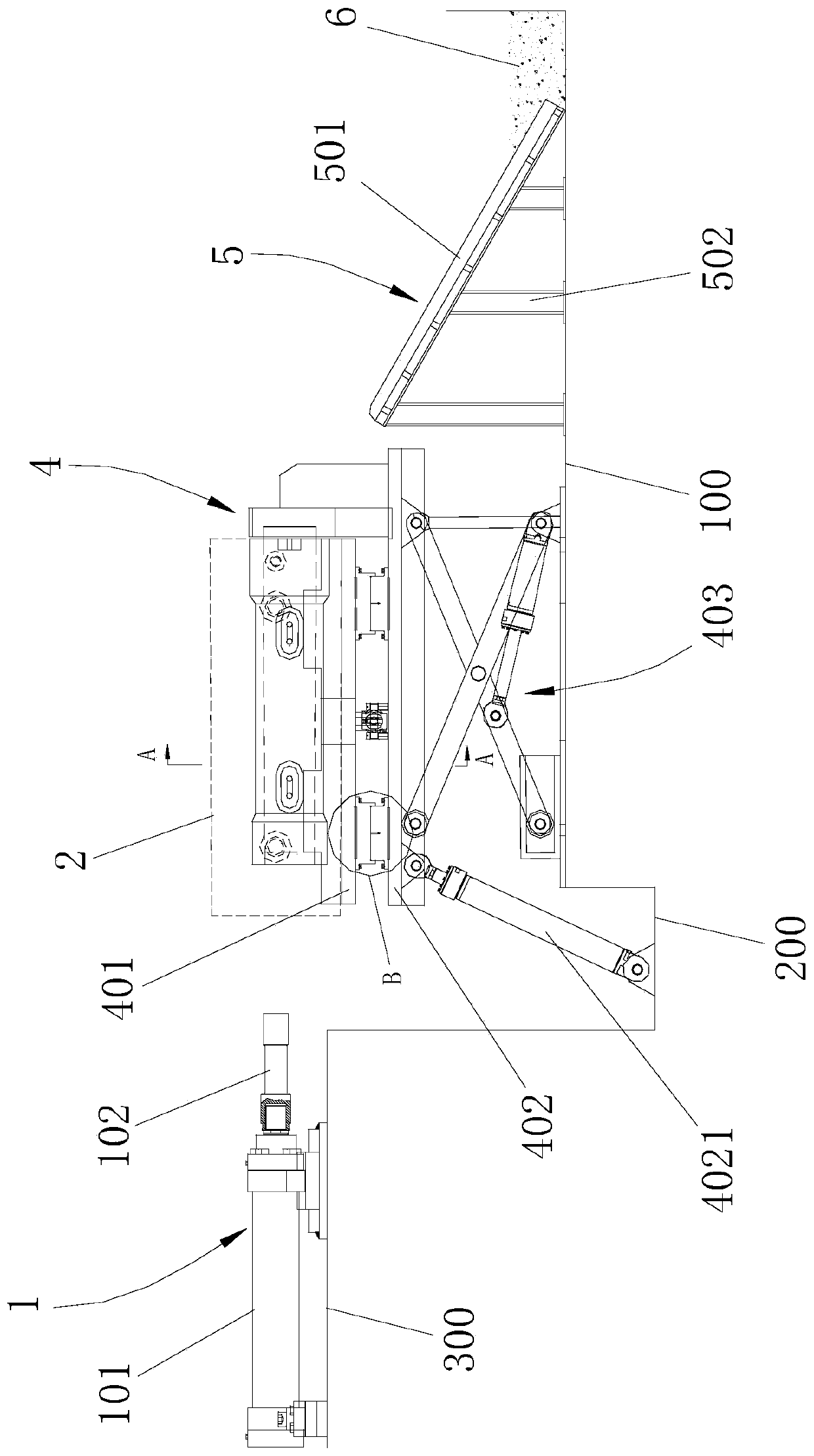

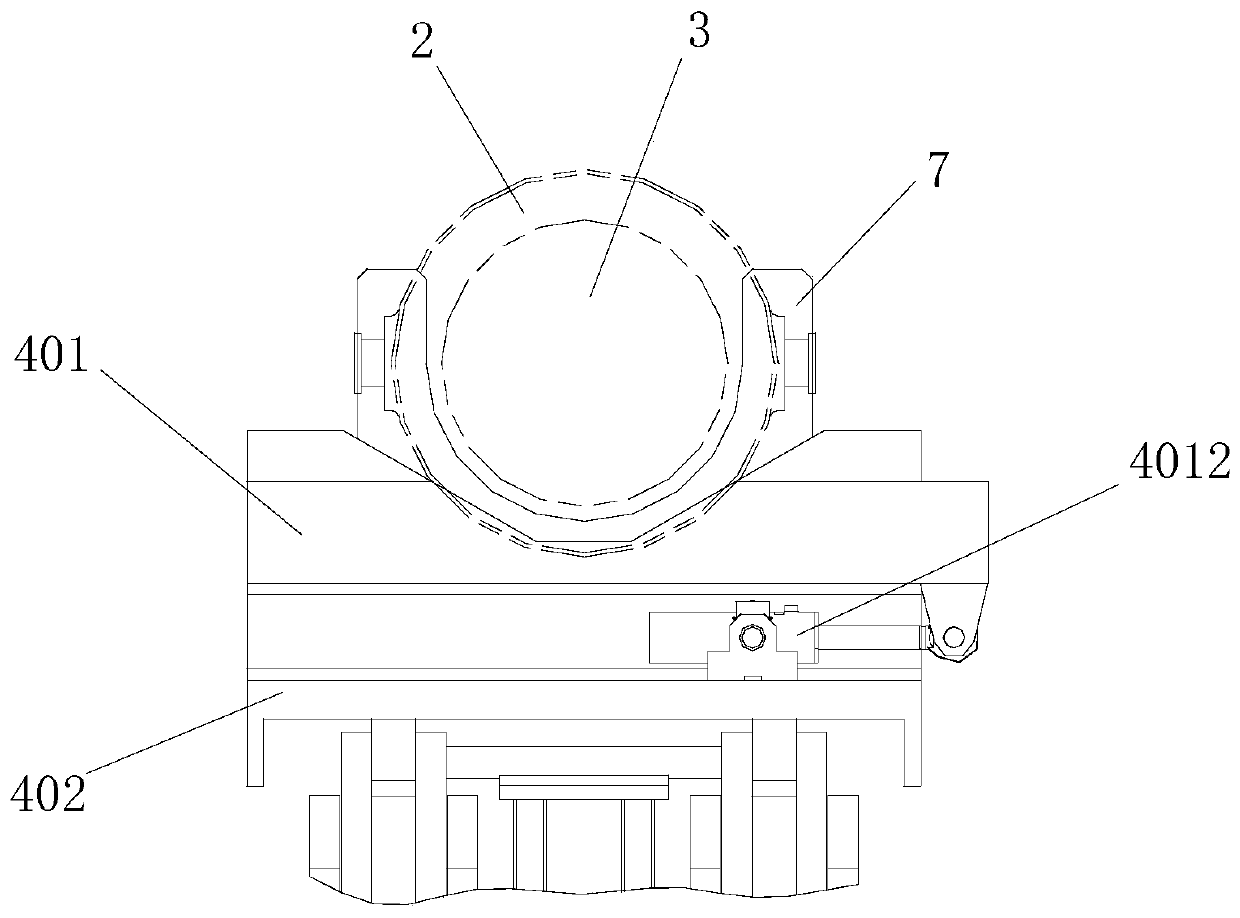

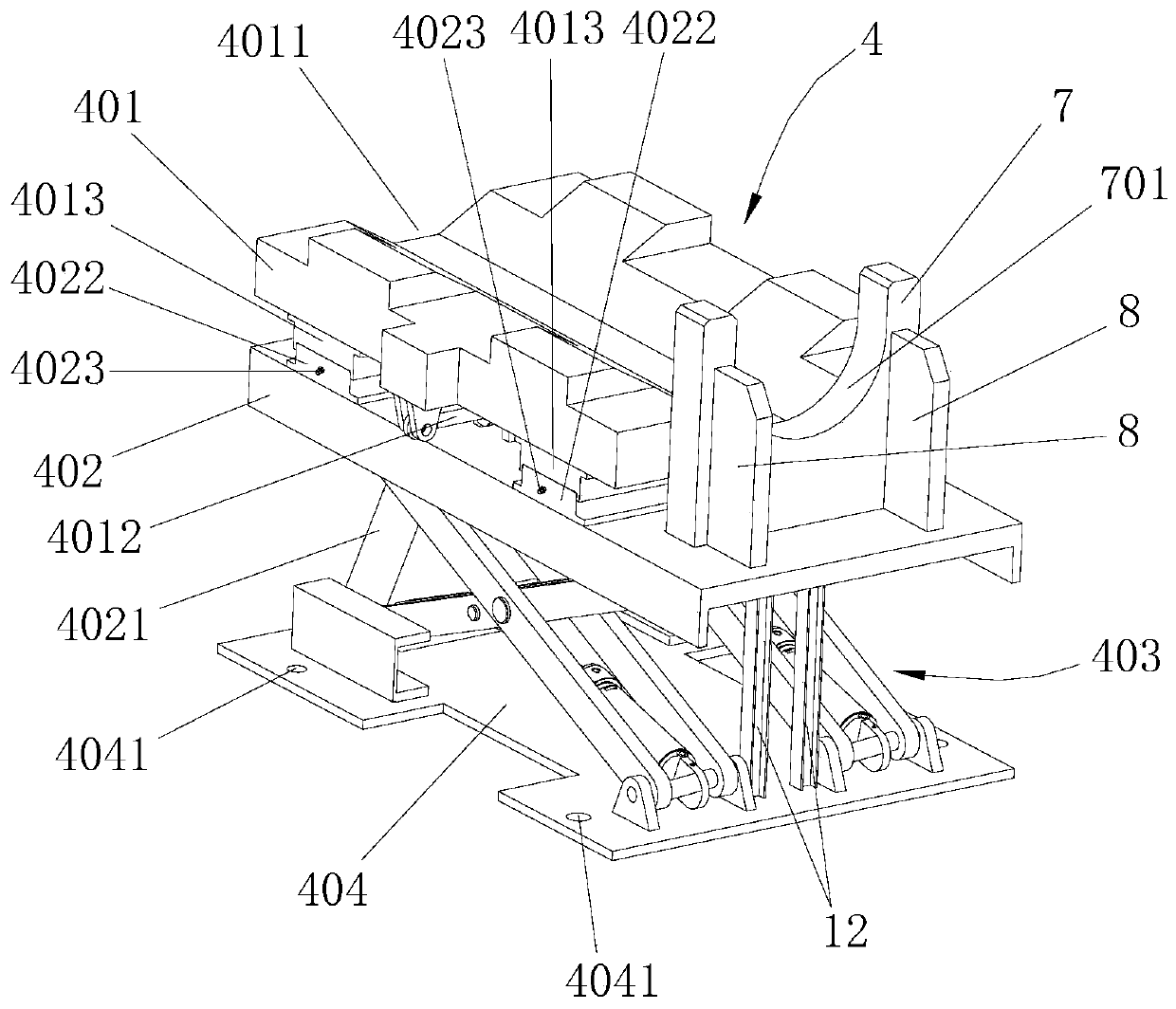

[0084] Such as Figure 1 to Figure 8 As shown, the present invention provides a demoulding unit, which includes a ejector device 1, a multi-degree-of-freedom lifting and turning device 4 and a guide device 5, and the ejector device 1 is used for the induction rod 3 in the steel ingot mold 2 Apply a thrust to separate the outer wall of the induction rod 3 from the inner wall of the ingot mold 2; the multi-degree-of-freedom lifting and turning device 4 is used to adjust the centering position and inclination angle of the induction rod 3; the guide device 5 is used to connect with the ingot mold 2 The separated sensing rod 3 is output to the receiving buffer 6 . Wherein: the multi-degree-of-freedom lifting and turning device 4 comprises a mobile platform 401, a turning platform 402 and a lifting mechanism 403, the moving platform 401 and the turning platform 402 are rectangular flat structures arranged along the horizontal direction, and the bottom of the lifting mechanism 403 is...

Embodiment 2

[0118] Such as figure 1 , Figure 8 As shown, the invention provides a kind of demoulding method, and this demoulding method comprises the steps:

[0119] Step S1: Fix the position of the ejector device 1, the multi-degree-of-freedom lifting and turning device 4 and the guiding device 5. The ejecting device 1 and the guiding device 5 are respectively located on both sides of the multi-degree-of-freedom lifting and turning device 4, and the guiding device 5 is located near the On the side of the receiving buffer zone 6, the ejector device 1 is located away from the side of the receiving buffer zone 6, and the lifting mechanism 403 of the multi-degree-of-freedom lifting and turning device 4 is lowered to the lowest position;

[0120] Wherein, the lowest position of the lifting mechanism 403 can be adjusted according to the specifications of the largest steel ingot mold 2, so as to ensure that the largest steel ingot mold 2 can be completely separated from the induction rod 3 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com