Method for rapidly replacing cutter capacity of numerical control machine tool

A replacement method and technology of CNC machine tools, applied in the direction of manufacturing tools, metal processing mechanical parts, positioning devices, etc., can solve the problems of increased processing procedures, low efficiency, time-consuming, etc., to improve tool replacement efficiency, speed and flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

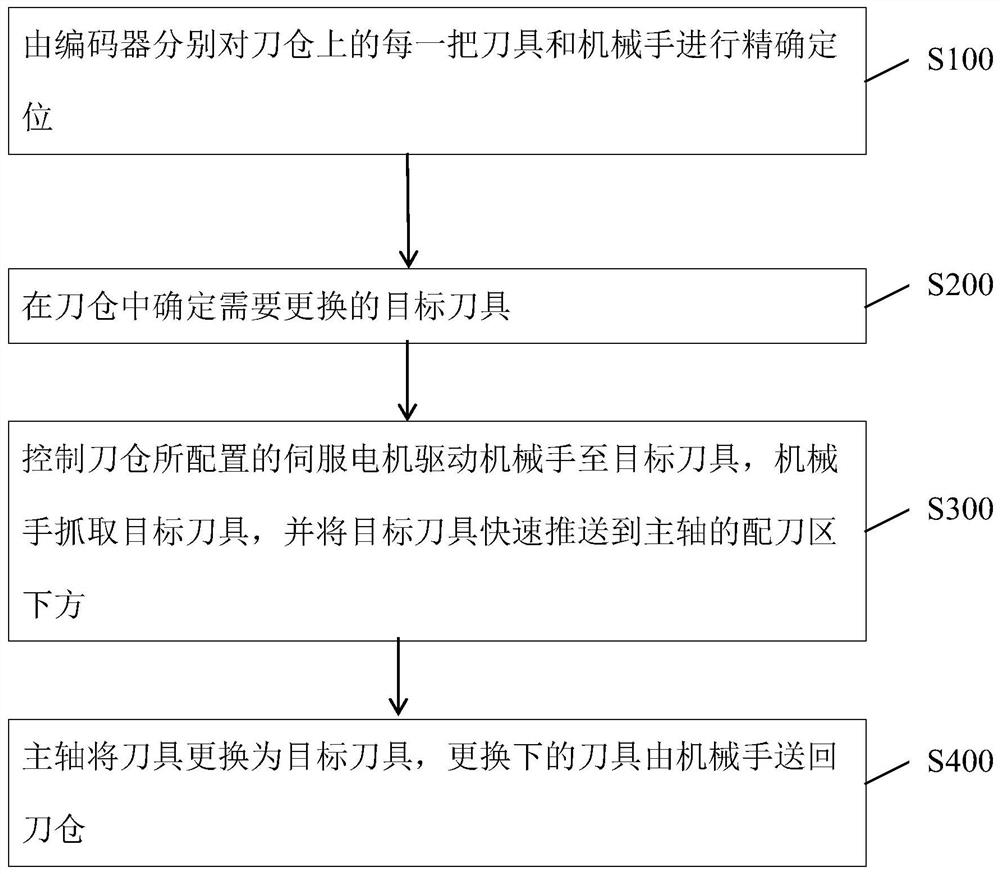

[0048] like figure 1 As shown, an embodiment of the present invention provides a method for rapidly replacing a tool capacity of a CNC machine tool, including the following steps:

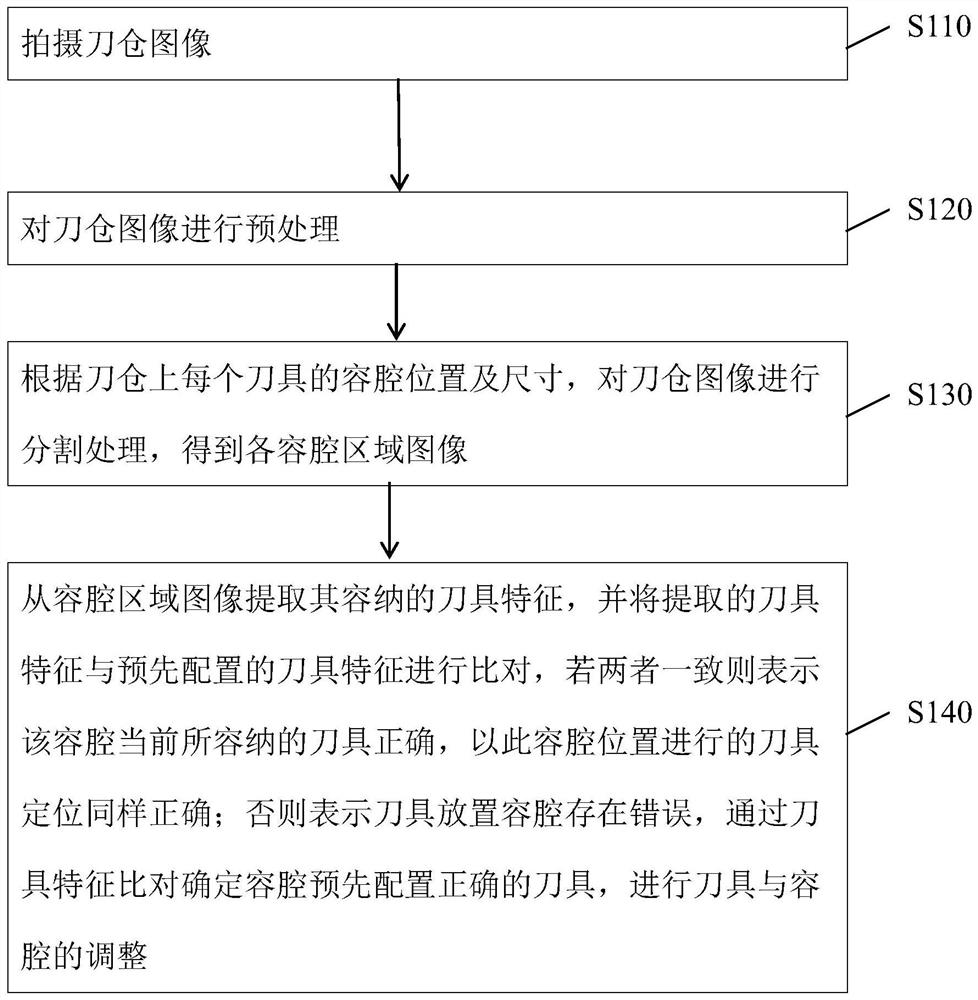

[0049] S100: Each tool and manipulator on the tool magazine are precisely positioned by the encoder;

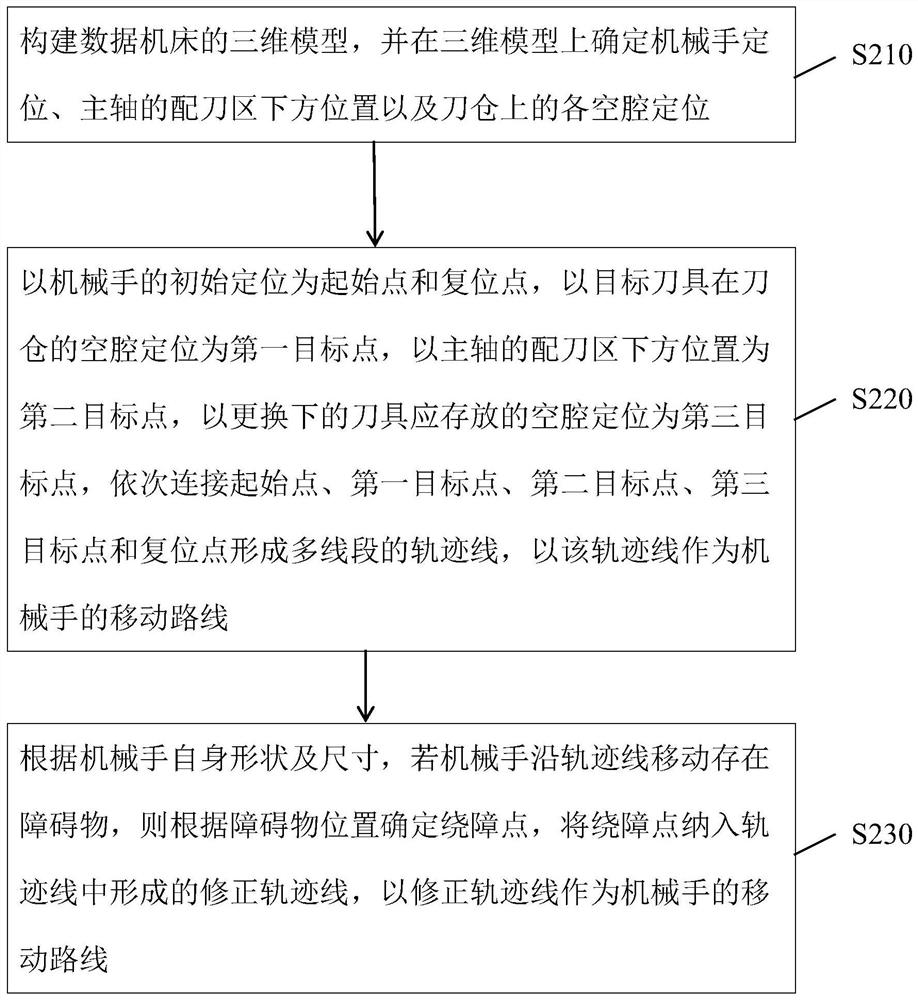

[0050] S200: Determine the target tool to be replaced in the tool magazine;

[0051] S300: Control the servo motor configured in the tool magazine to drive the manipulator to the target tool, the manipulator grabs the target tool, and quickly pushes the target tool to the bottom of the tool area of the spindle;

[0052] S400: The spindle replaces the tool with the target tool, and the replaced t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com