Preparation method of Ti2AlNb alloy large special-shaped casing ring piece

A special-shaped and large-scale technology, which is used in the preparation of Ti2AlNb alloy large-scale special-shaped casing rings, can solve problems such as uneven deformation of forgings, and achieve the effects of avoiding uneven deformation, reducing dependence and improving deformation uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

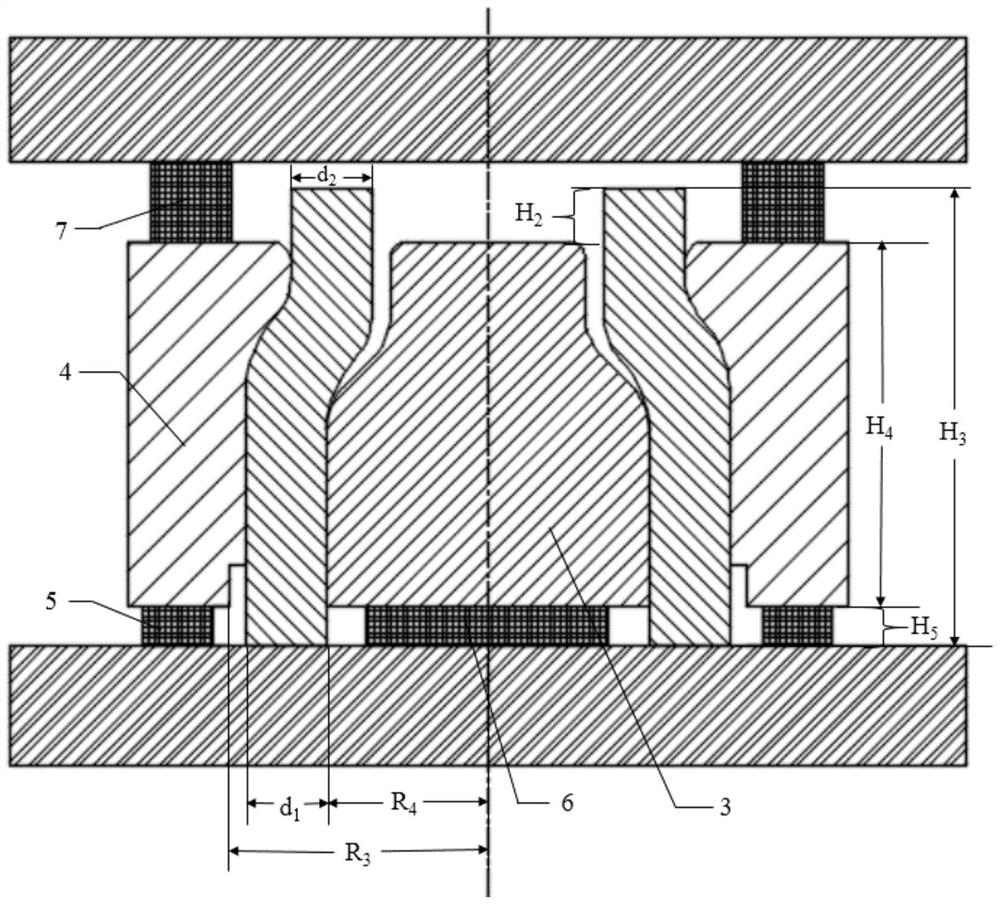

[0025] see Figure 1 to Figure 5 , in some embodiments of the present invention provides a Ti 2 The preparation method of AlNb alloy large special-shaped casing ring includes the following steps:

[0026] (A) Ti 2 AlNb alloy bars are subjected to upsetting, punching and pre-rolling treatments to obtain rectangular ring billets;

[0027] (B) the rectangular ring blank is loaded into the boring tire mold and carries out boring processing to obtain the special-shaped blank I;

[0028] (C) the small end of the special-shaped blank I is subjected to a boring process, and the small end of the special-shaped blank I is all pressed into the boring tire mold to obtain the special-shaped blank II;

[0029] (D) Turn the bulky tire mold and the special-shaped blank II as a whole at 180°C, and perform the bulky treatment on the big end of the special-shaped blank II. ;

[0030] (E) Rolling the special-shaped billet III to obtain Ti 2 AlNb alloy large special-shaped casing ring.

[0...

Embodiment 1

[0073] Ti provided in this example 2 The preparation method of AlNb alloy large special-shaped casing ring includes the following steps:

[0074] (A) in Ti 2 The surface of the AlNb alloy bar is evenly coated with thermal insulation coating, heated to 980 ℃, and the Ti 2 The AlNb alloy bar is heat-wrapped, and after being kept at 980°C for 60 minutes, upsetting with a deformation of 10% is performed to obtain a blank a; then the blank a is placed in the punching die 1, and the blank a is punched with a punch 2 Hole to obtain billet b; apply thermal insulation paint on the surface of billet b, heat it to 1030 ° C, heat the billet b after heat penetration, and carry out pre-rolling with a total deformation of 15% after holding at 1030 ° C for 60 minutes to obtain a rectangular ring billet ;

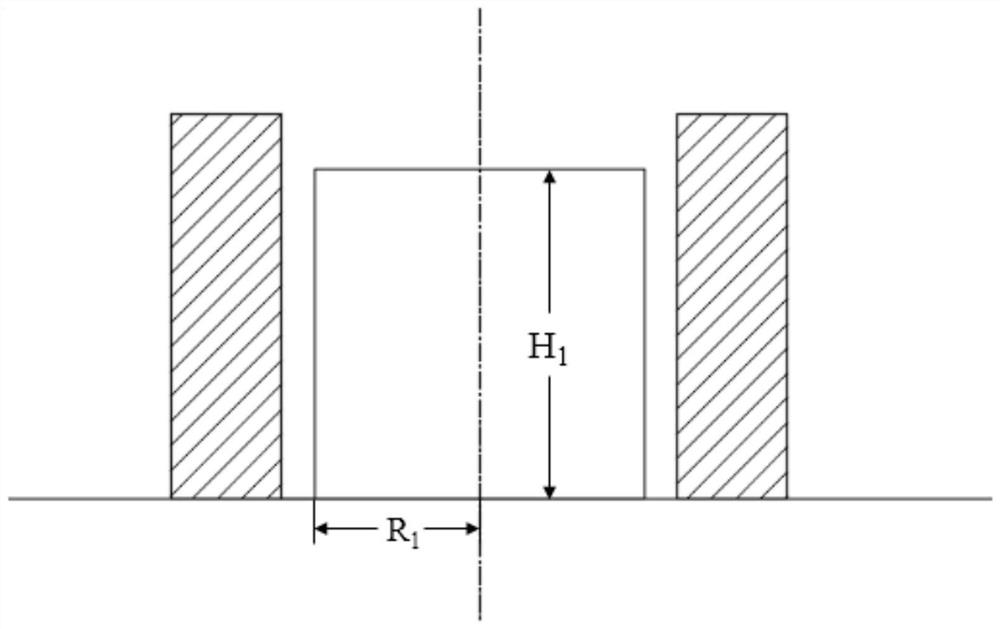

[0075] Among them, the inner hole radius of the punching tire mold 1 In the formula, R 1 is the radius of the blank a; the H 1 is the height of blank a, r 1 is the inner hole radius...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com