Method for bending bridge U-shaped rib in ignition general yield manner by adopting special clamping device

A clamping device and U-shaped technology, which is applied in the field of bridge manufacturing, can solve the problems that the deformation cannot be transmitted to the other side, the U-shaped rib cannot be bent, and the U-shaped rib cannot be deformed, so as to achieve low investment, high production efficiency, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

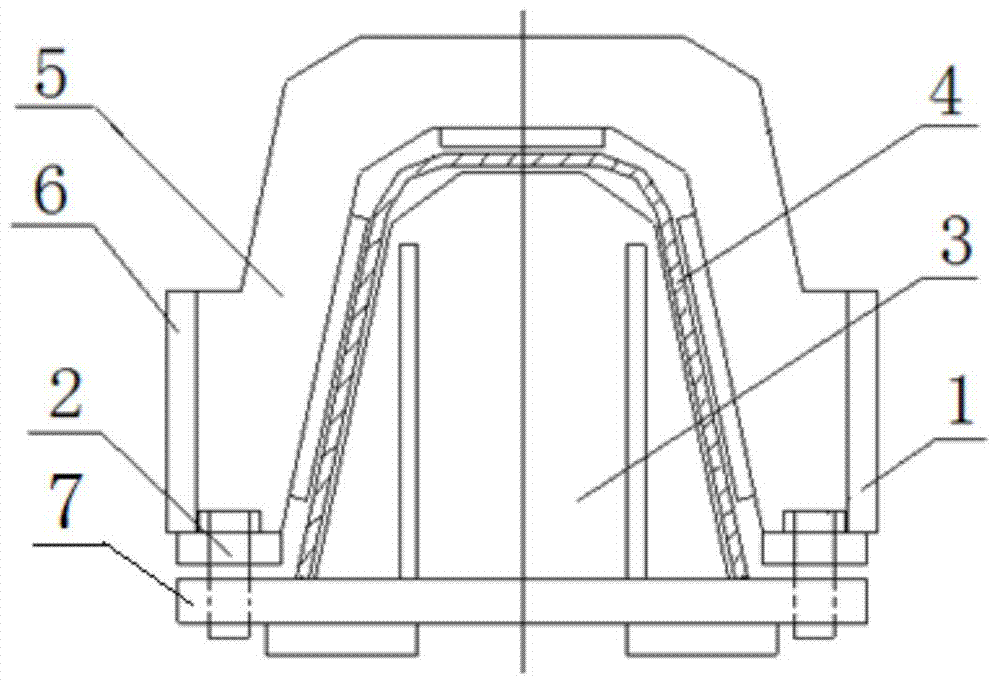

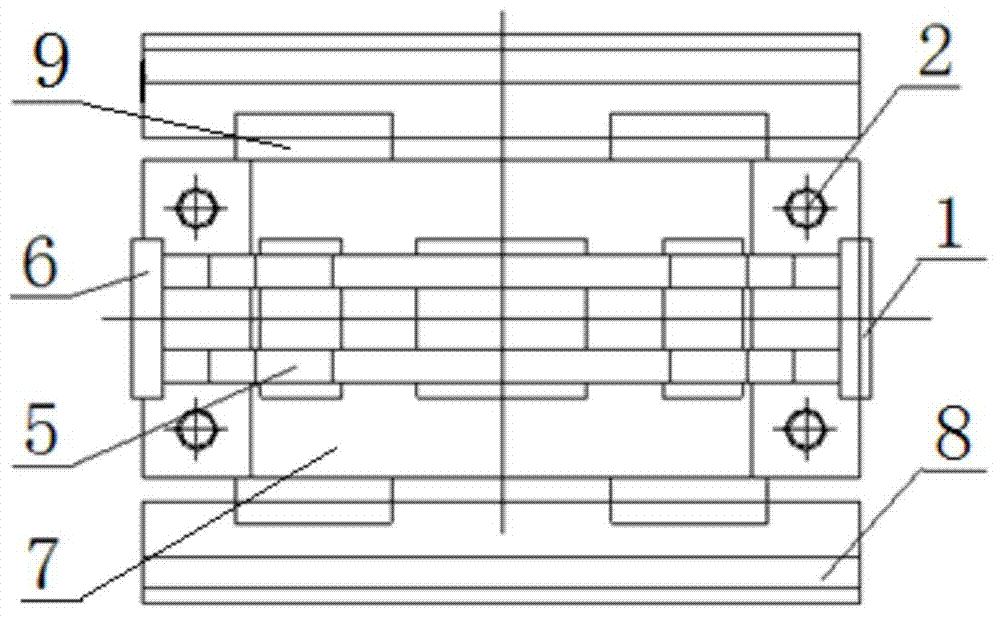

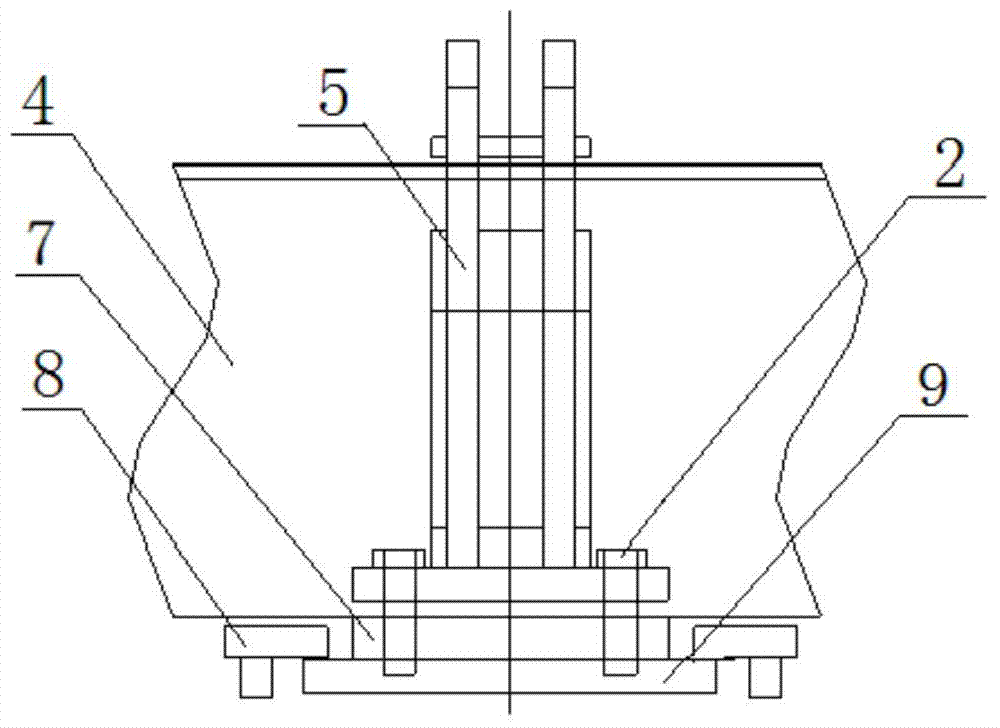

[0027] Embodiment 1: A special clamping device for bending U-shaped ribs provided by the present invention, its structure is as follows figure 1 , 2 Shown in and 3, include inner template 3, outer die 5, guide rail 8 and base plate 7, described inner template is welded on the base plate, base plate 7 is welded on the slider 9, inner template 3, base plate 7 and slider 9 Formed in one piece, slide in the guide rail 8 together. The outer die 5 is covered outside the inner template. When the special clamping device is used, the inner template 3 is covered in the U-shaped rib to be bent, and the outer die 5 and the inner template 3 are correspondingly installed outside the U-shaped rib to be bent. The lower ends of both sides of the outer die 5 are respectively processed with 2 bolt holes, the outer die 5 is fixed on the bottom plate 7 by bolts 2, and the two ends of the outer die 5 are equipped with a pressure plate 1 and a baffle plate 6 respectively; A jack 11 is installed on...

Embodiment 2

[0037] Embodiment 2: The present invention provides a kind of method that adopts the special clamping device described in embodiment 1 pyrotechnic full yield to bend the method for bridge U-shaped rib, bends a 16 meters long, plate thickness 8 millimeters, bottom width 300 millimeters , U-shaped ribs for bridges with a height of 280 mm, its operation steps are basically the same as in embodiment 1, the difference is that a U-shaped rib bending work platform is formed by 7 workbenches 13, and each workbench is spaced at 2.2 meters. When each hot bending point section is heated one by one, the temperature of the flame drying gun is controlled at 830-890°C, and the heating time of the drying gun is 30 seconds, so that the entire section of the heating can reach above 800°C at the same time. Full yield; each section of the hot bending point is pyrotechnically heated one by one, and then cooled sequentially to make the entire U-shaped rib bend and shape.

[0038] The special U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com