Performance detection module for automobile electronic water valve

A technology for automotive electronics and detection molds, applied in the direction of mechanical valve testing, etc., can solve problems such as errors in results, inability to reuse water, and inability to display test results, and achieve the effect of improving test efficiency and reducing test costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

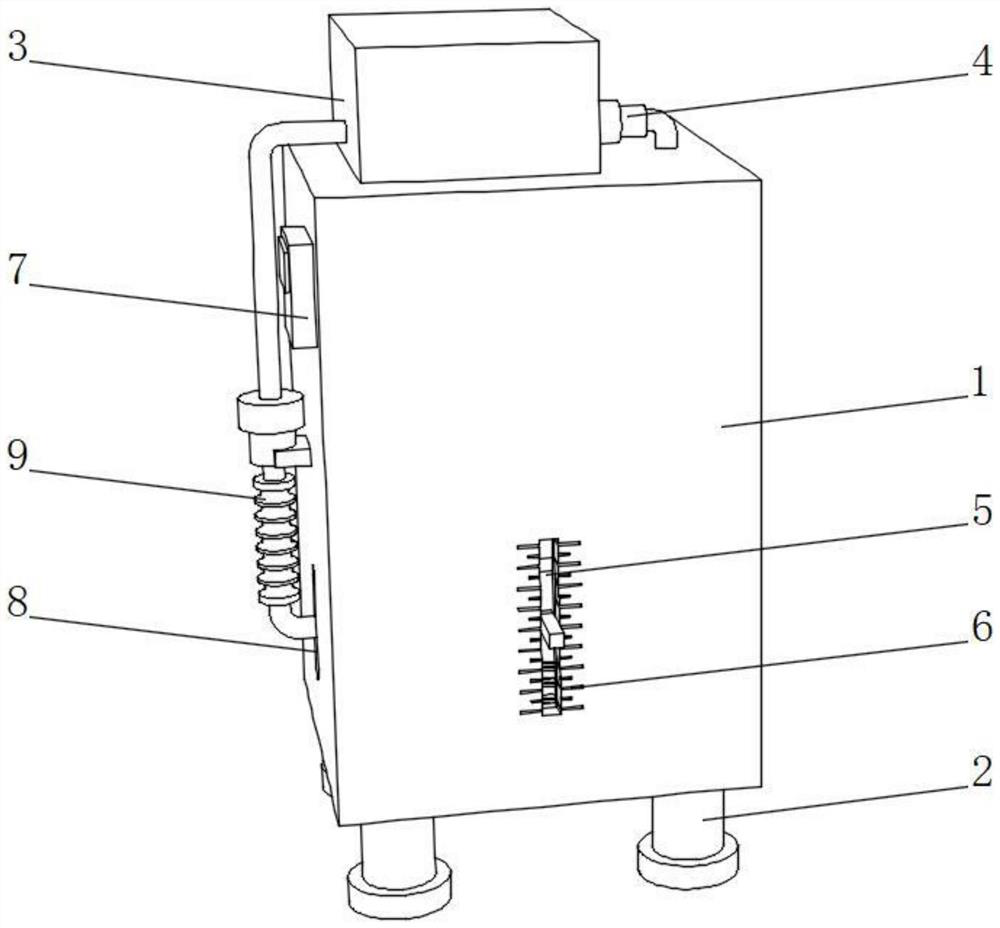

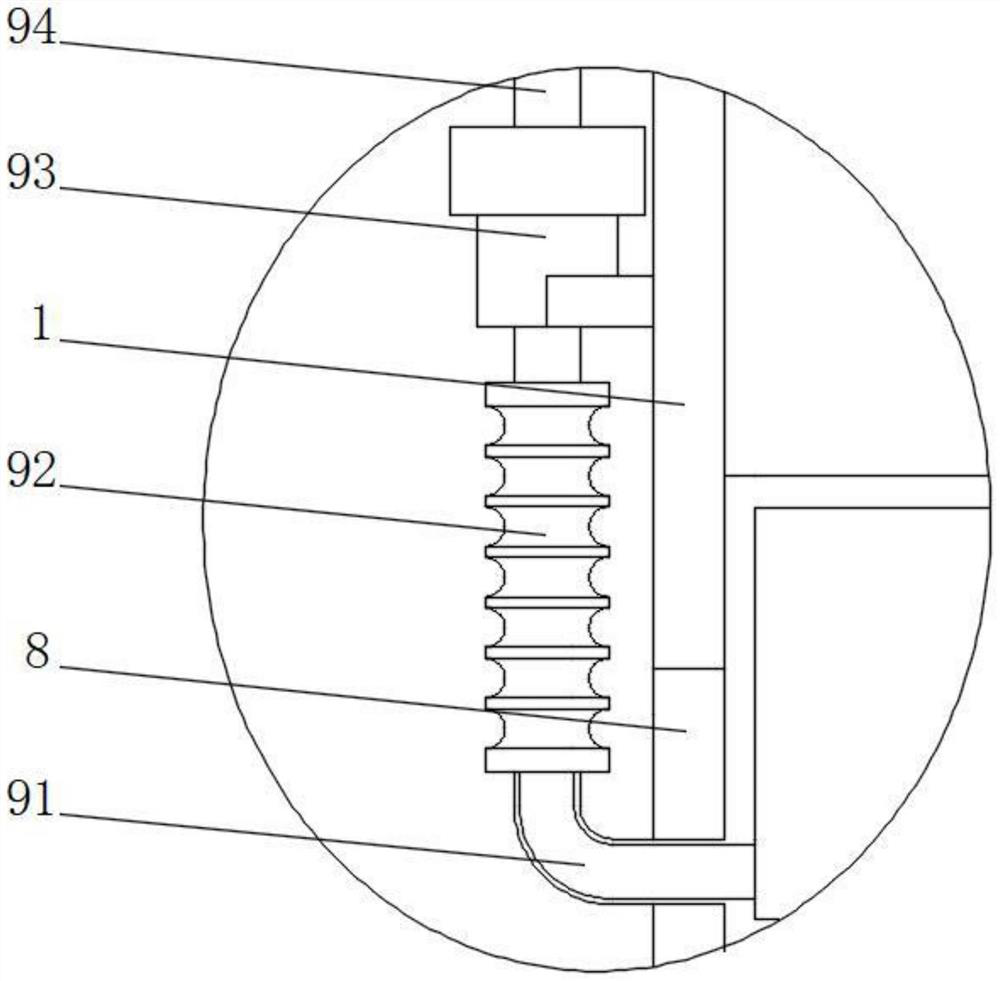

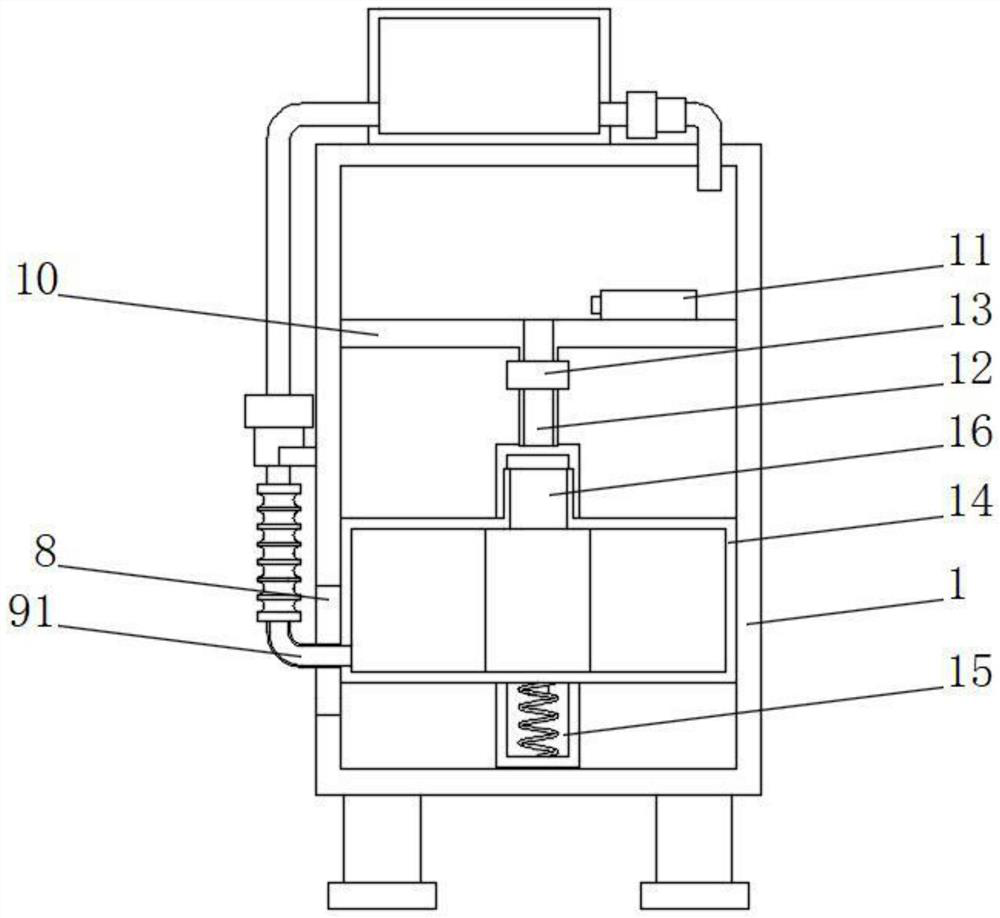

[0024] see figure 1 , figure 2 and image 3 , A performance detection module for an automobile electronic water valve proposed by the present invention includes a box body 1, a support leg 2 is fixedly connected to the bottom of the box body 1, a water tank 3 is fixedly connected to the top side of the box body 1, and the water tank 3 One side of the first connecting pipe is connected with a first connecting pipe, one end of the first connecting pipe penetrates the top wall of the box 1 and extends to the inside, the surface of the first connecting pipe is fixedly connected with the first water pump 4, and the front of the box 1 is on the back. Through holes 5 are opened on the surface of the box body 1 and scale lines 6 are opened on both sides of the through hole 5. One side of the box body 1 is fixedly connected with the controller 7, and one side of the box body 1 is provided with a movable hole 8. , one side of the movable hole 8 is provided with a circulation mechanis...

Embodiment 2

[0031] see image 3 and Figure 4 , as an improvement of the above scheme, the inside of the box body 1 is slidably connected with a collection box 14, the top of the collection box 14 is fixedly connected with a receiving pipe 16, and the second connecting pipe 91 passes through the movable hole 8 and is fixed to one side of the collection box 14 A sliding mechanism 15 is arranged between the surface of the collection box 14 and the inner wall of the box body 1. In the present invention, the collection box 14, the sliding mechanism 15, the sliding block 151, the sliding rail 152, the spring 153, the indicator rod 154, the receiving pipe 16. The amount of water in the collection box 14 can be visually displayed through the compression degree of the spring 153, and the amount of water in the collection box 14 can be displayed through the indicator rod 154 and the scale line 6, so that the test results are more intuitive and clear, Improve test efficiency.

[0032] As an impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com