Negative-pressure clean sampling chamber

A sampling room, clean technology, applied in the field of sampling room, can solve the problems of increasing infection, weak protection of sampling personnel, etc., to achieve the effect of convenient transportation and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

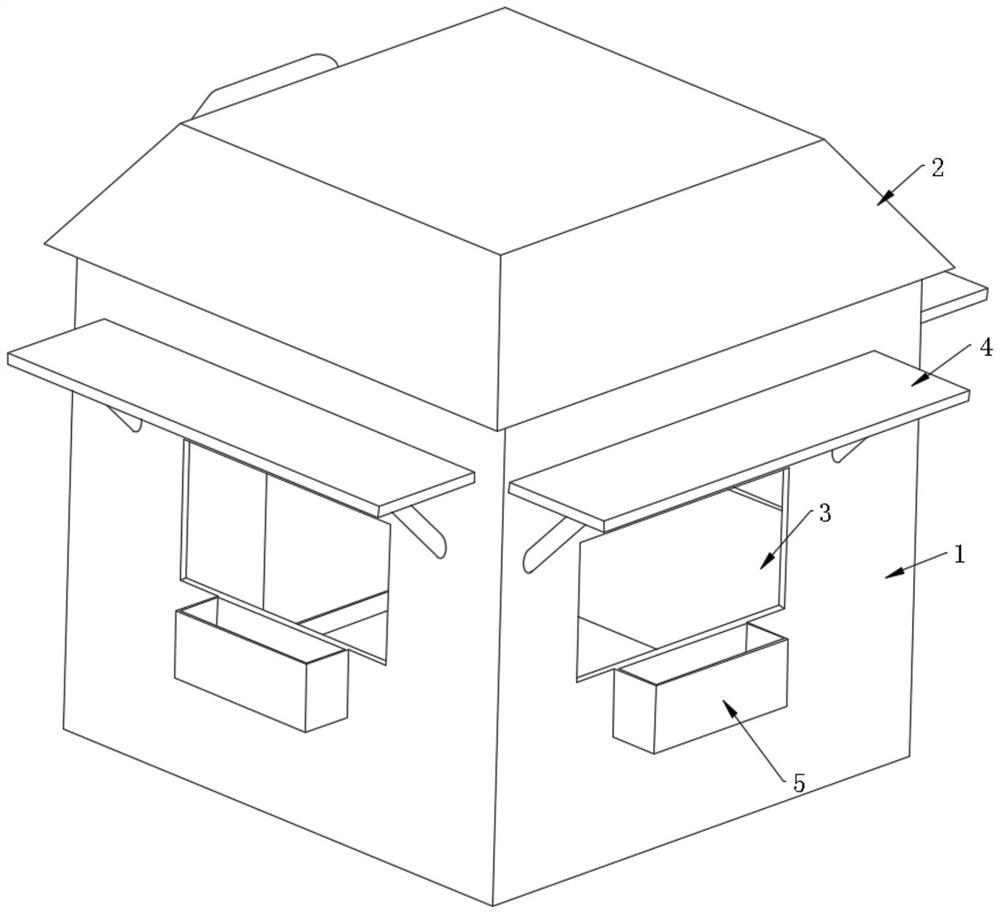

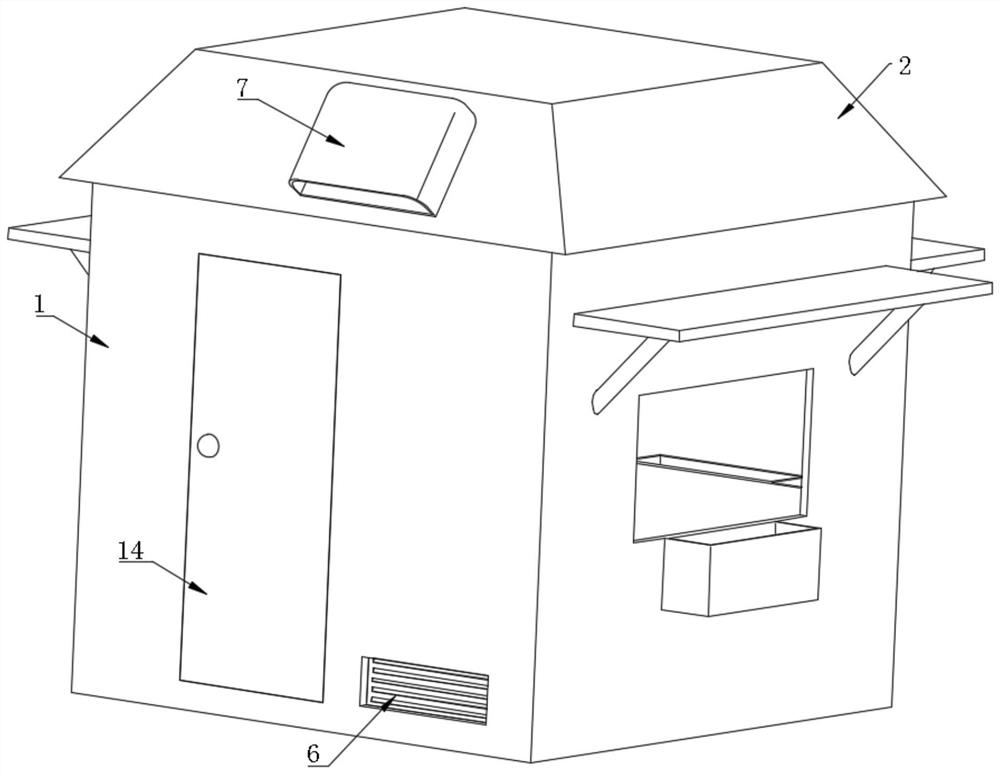

Embodiment 1

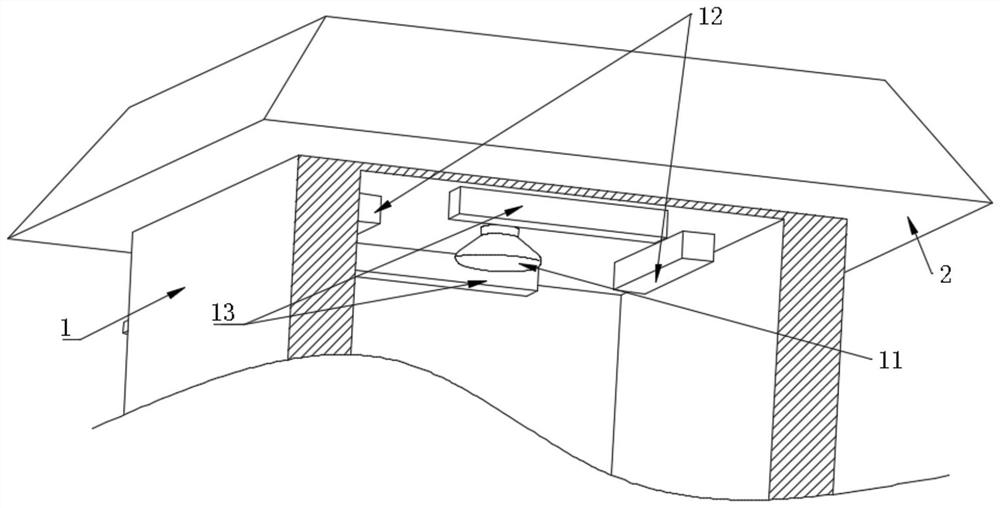

[0024] Embodiment 1: The fresh air outlet 11 is connected to the purification unit 10, and is located at the inner top of the house body 1, and a bottom air outlet 6 is also opened at the inner bottom of the house body 1.

Embodiment 2

[0025] Embodiment 2: The fresh air outlet 11 is connected to the purification unit 10 and is located directly above the sampling window 3 in the room 1 , and the bottom air outlet 6 is also opened on the inner bottom of the room 1 .

[0026] When the present invention is used, the staff can be located in the interior of the house 1, and the staff can be sampled through the sampling window 3. After the sampling is completed, the waste can be thrown into the collection box 5, and at the same time, the purification unit 10 can be turned on synchronously. , the purification unit 10 can extract fresh air from the outside of the room 1 and enter the air purifier through the fresh air duct 9 , and the purified fresh air will be discharged from the fresh air outlet 11 .

[0027] It can be seen from the first embodiment that fresh air will be discharged from the top of the room body 1, and promote the circulation of the air inside the room body 1, and the exhaust gas will be discharged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com