Sleeve supporting structure of large liquid hydrogen vacuum double-layer spherical tank

A support structure and liquid hydrogen technology, applied in the field of large-scale liquid hydrogen storage, to achieve the effect of improving thermal insulation performance, increasing thermal conductivity and reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

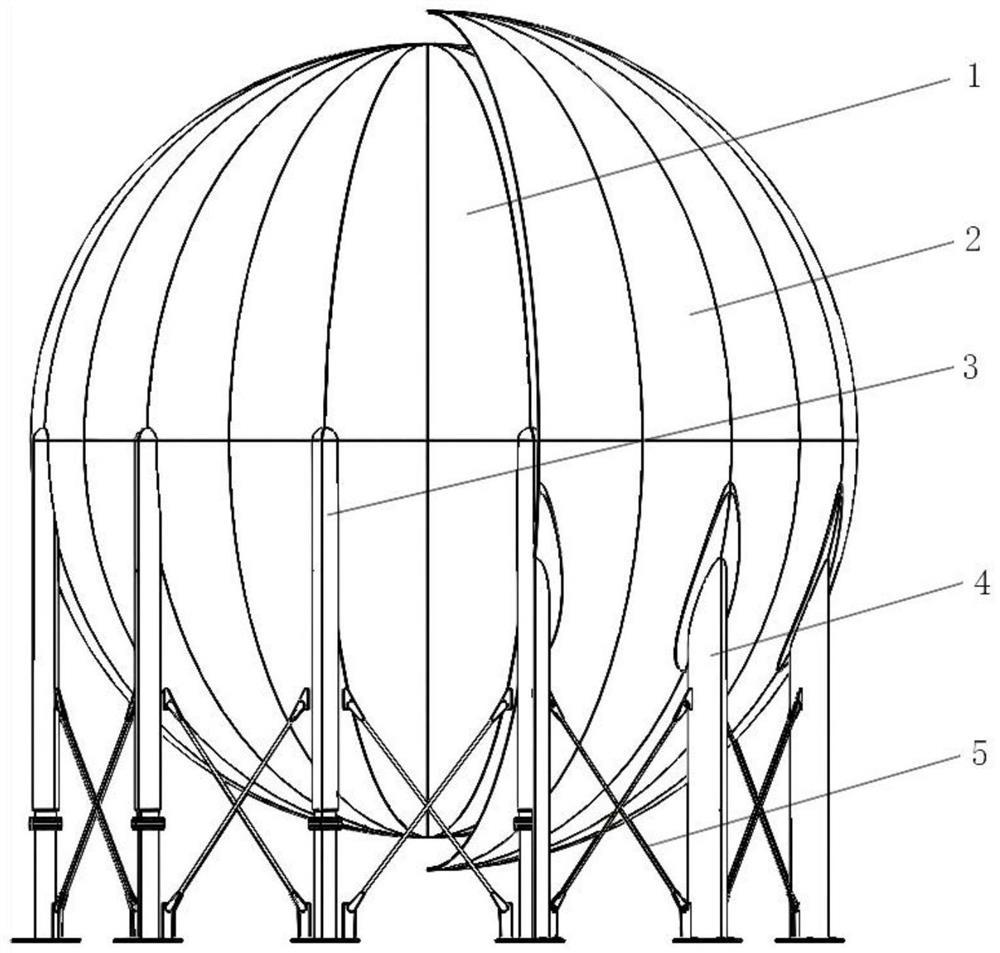

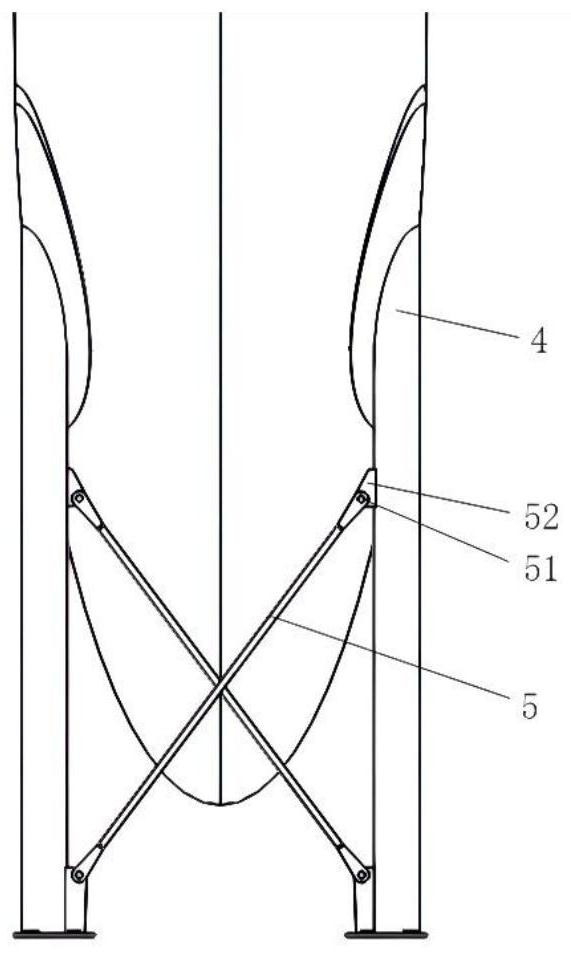

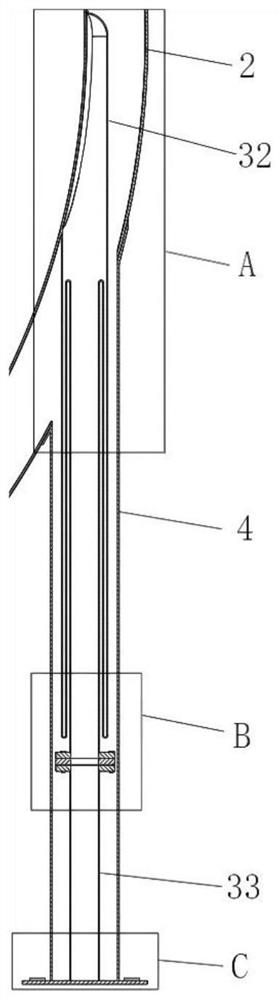

[0027] like figure 1 , figure 2 As shown, a casing support structure of a large-scale liquid hydrogen vacuum double-layer spherical tank includes an inner support 3, an outer support structure 4 and a tie rod 5. The inner tank 1 is suspended in the cavity of the outer tank 2 through the inner support 3. The inner tank 1 and the outer tank 2 are filled with thermal insulation material and pumped into a high vacuum state for thermal insulation. The thermal insulation material adopts multi-layer thermal insulation material or pearl sand; the outer tank 2 is supported by the outer support structure 4, and the adjacent outer support A tie rod 5 is connected between the structures 4 .

[0028] The inner tank 1 and the outer tank 2 are provided with several groups of support structures for supporting the inner tank 1 and the outer tank 2. Each group of support st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com