Rib positioning gypsum-based thermal insulation slurry floor heating system and construction method

A thermal insulation slurry and gypsum-based technology, applied in hot water central heating systems, electric heating systems, heating systems, etc., can solve the problems of high overall cost, low construction efficiency, and insufficient durability, and achieve stable body shape and improve heat dissipation efficiency, quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The materials selected in this embodiment include desulfurized gypsum polystyrene particle foam concrete, floor heating heating pipes and plastic staples with matching diameters, pine wood strips, and polyethylene foam tampons with single-sided adhesive, all of which are commonly available in the market.

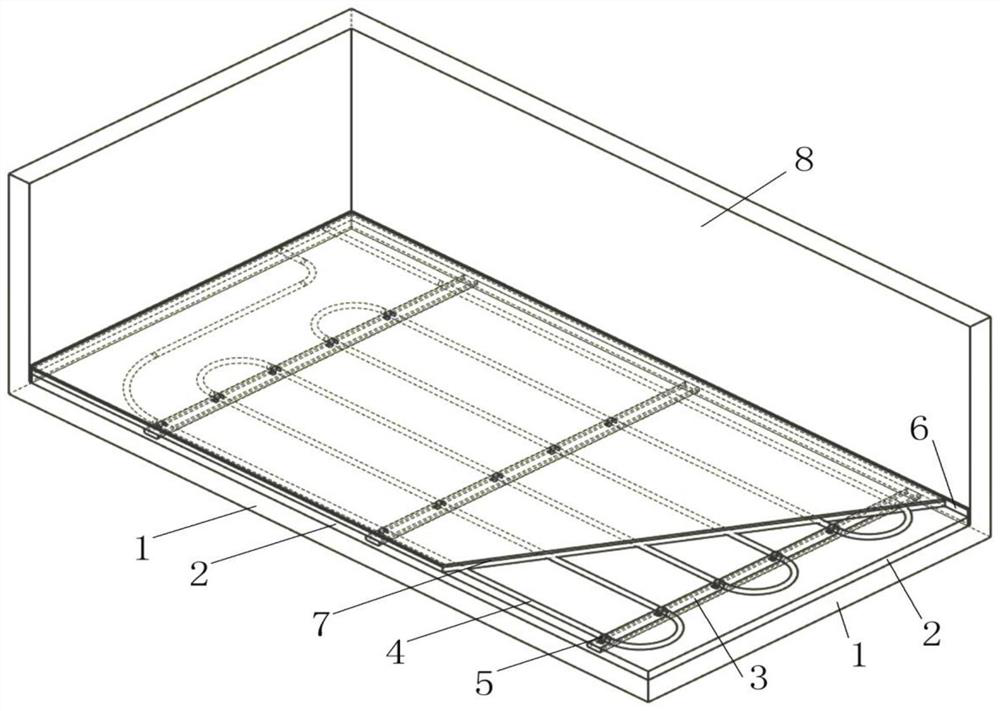

[0035] The rib-positioned gypsum-based thermal insulation slurry floor heating system of this embodiment, such as figure 1 As shown, it consists of a thermal insulation layer 2, a positioning rib 3, a heating tube 4, a heating tube clip 5, a thermal insulation strip 6, and a filling layer 7; the thermal insulation layer 2 is cast on the floor 1 with gypsum-based thermal insulation slurry; the positioning rib 3. It is pasted on the floor 1 with mortar, and its upper surface is flush with the surface of the thermal insulation layer 2; the heating pipe 4 is fixed on the positioning rib 3 with the heating pipe clip 5; The filling layer 7 is corresponding and the height is...

Embodiment 2

[0046] The materials selected in this embodiment include desulfurized gypsum thermal insulation mortar, floor heating heating pipes and plastic staples with matching diameters, PVC square strips, polyethylene foamed cotton strips with single-sided adhesive, dry hard cement mortar and floor tiles, all of which are commonly available in the market. Material.

[0047] The rib-positioned gypsum-based thermal insulation slurry floor heating system of this embodiment, such as figure 1 As shown, it consists of a thermal insulation layer 2, a positioning rib 3, a heating tube 4, a heating tube clip 5, a thermal insulation strip 6, and a filling layer 7; the thermal insulation layer 2 is cast on the floor 1 with gypsum-based thermal insulation slurry; the positioning rib 3. It is pasted on the floor 1 with mortar, and its upper surface is flush with the surface of the thermal insulation layer 2; the heating pipe 4 is fixed on the positioning rib 3 with the heating pipe clip 5; The fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com