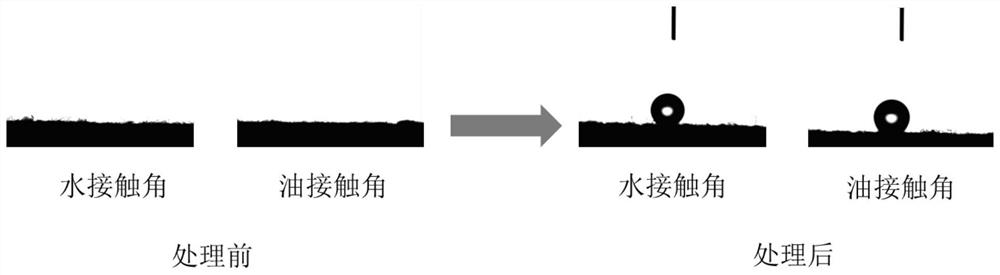

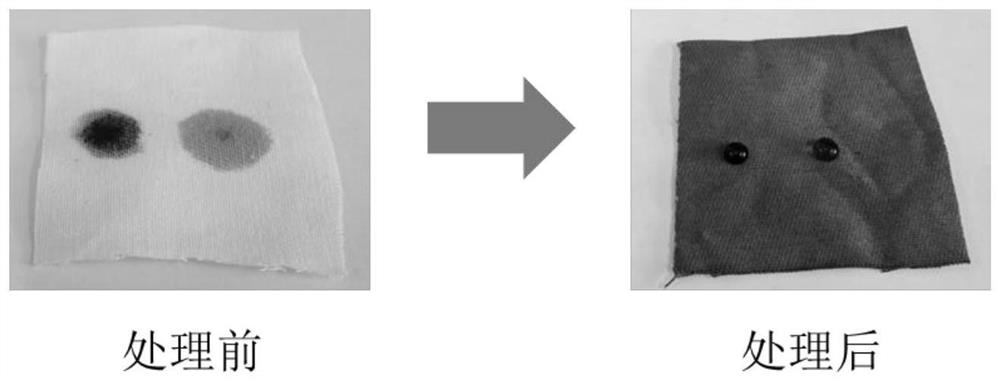

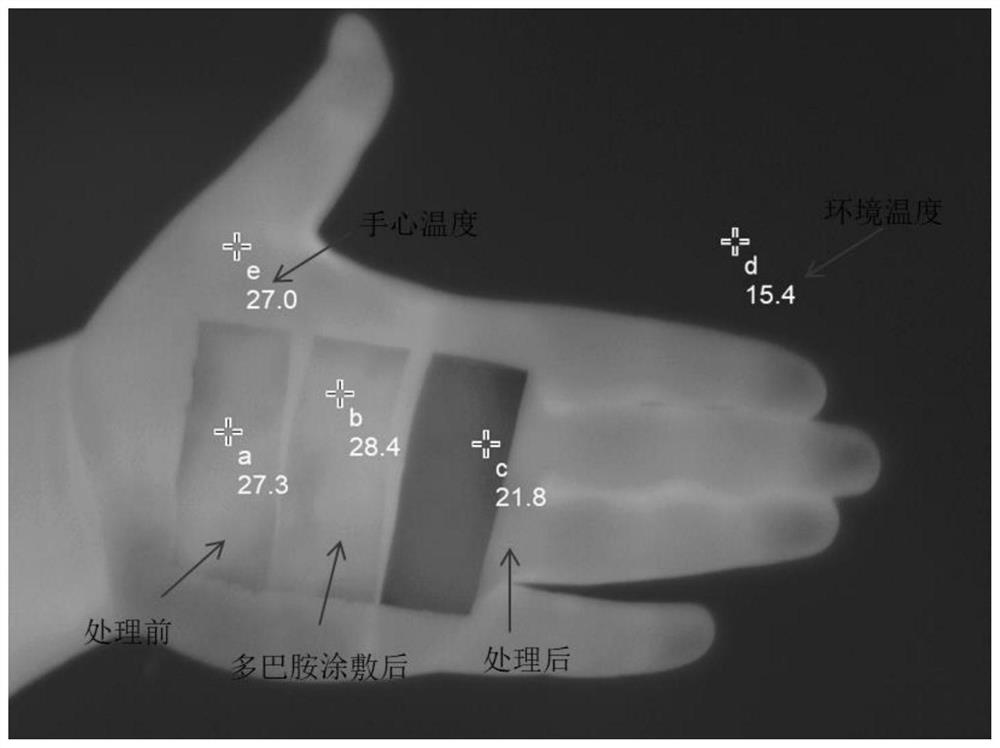

Super-amphiphobic infrared stealth fabric and preparation method thereof

A super-double-sparse, fabric technology, applied in the direction of animal fibers, plant fibers, textiles and papermaking, etc., to achieve high firmness, excellent infrared stealth properties, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) prepare the dopamine aqueous solution with a concentration of 1wt%, adjust the pH value to 7.5, then immerse the fabric (cotton) in the above-mentioned dopamine aqueous solution for 8 hours, then wash and dry;

[0035] (2) Preparation of functional coating solution: adding hydrotalcite, hollow silica, polyurethane, nano-silver powder, and all (17) fluorodecyltriethoxysilane to tetrahydrofuran for dispersion, wherein the addition of hydrotalcite The dosage is 1wt%, the dosage of hollow silica is 2wt%, the dosage of polyurethane is 5wt%, the dosage of nano silver powder is 3wt%, the dosage of all (17) fluorodecyltriethoxysilane is is 3wt%;

[0036] (3) Immerse the fabric after cleaning and drying in step (1) into the functional coating solution prepared in step (2), soak for 1 minute, and heat at 50° C. for 30 minutes to obtain the desired super-amphiphobic infrared Stealth fabric.

Embodiment 2

[0038] (1) prepare the dopamine aqueous solution with a concentration of 2wt%, adjust the pH value to 8, then immerse the fabric (polyester cloth) in the above-mentioned dopamine aqueous solution for 12 hours, then wash and dry;

[0039] (2) Preparation of functional coating solution: adding hydrotalcite, hollow silica, polyurethane, nano-silver powder, and all (17) fluorodecyltriethoxysilane to tetrahydrofuran for dispersion, wherein the addition of hydrotalcite The addition amount is 2 wt %, the addition amount of hollow silica is 1 wt %, the addition amount of polyurethane is 1 wt %, the addition amount of nano silver powder is 1 wt %, and the addition amount of all (17) fluorodecyl triethoxysilane is 1wt%;

[0040] (3) Immerse the fabric after cleaning and drying in step (1) into the functional coating solution prepared in step (2), soak for 5 minutes, and heat at 100° C. for 5 minutes to obtain the desired super-amphiphobic infrared Stealth fabric.

Embodiment 3

[0042] (1) prepare the dopamine aqueous solution with a concentration of 3wt%, adjust the pH value to 9, then immerse the fabric (wool cloth) in the above-mentioned dopamine aqueous solution for 24 hours, then wash and dry;

[0043] (2) Preparation of functional coating solution: adding hydrotalcite, hollow silica, polyurethane, nano-silver powder, and all (17) fluorodecyltriethoxysilane to tetrahydrofuran for dispersion, wherein the addition of hydrotalcite The amount of the powder is 3wt%, the amount of hollow silica is 5wt%, the amount of polyurethane is 3wt%, the amount of nano silver powder is 5wt%, the amount of all (17) fluorodecyl triethoxysilane is added is 2wt%;

[0044] (3) Immerse the fabric after cleaning and drying in step (1) into the functional coating solution prepared in step (2), soak for 3 minutes, and heat at 80° C. for 15 minutes to obtain the desired super-amphiphobic infrared Stealth fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com