Polyamide composition and manufacturing method for manufacturing sliding and rolling parts by using same

A polyamide composition, polyamide technology, applied in the field of polyamide composition and the manufacture of sliding and rolling parts made of it, can solve the loss of material ductility and toughness, large surface roughness of parts, increase of dynamic friction coefficient, etc. problem, to achieve the effect of excellent appearance and low Ra value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] sample preparation

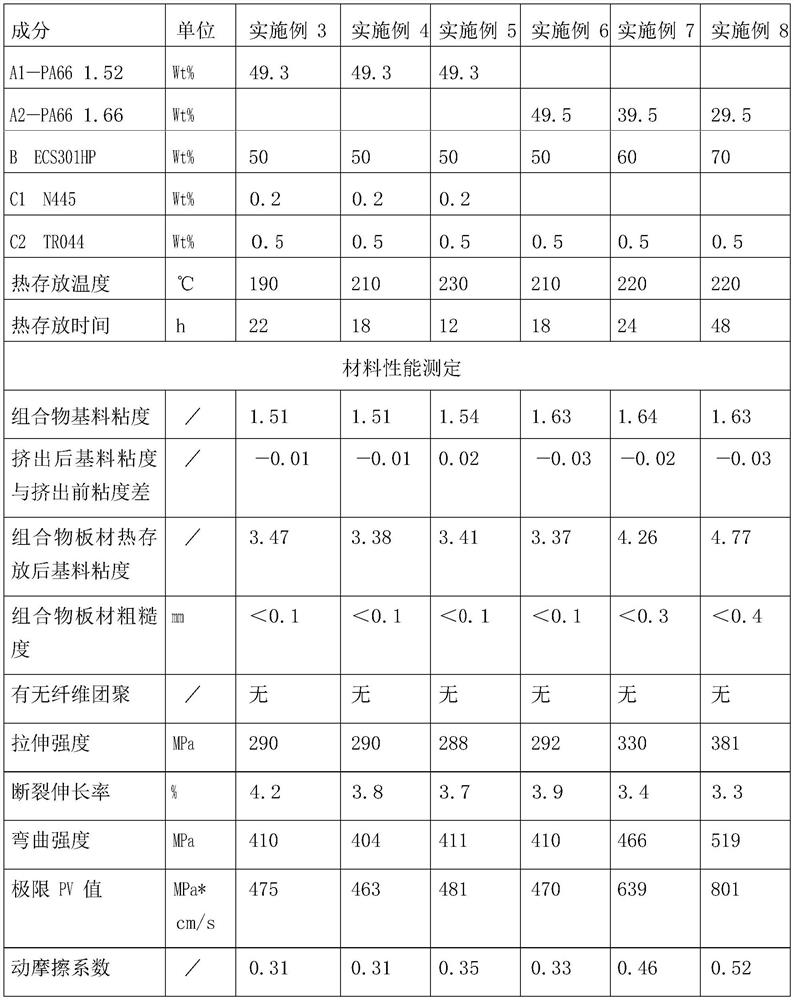

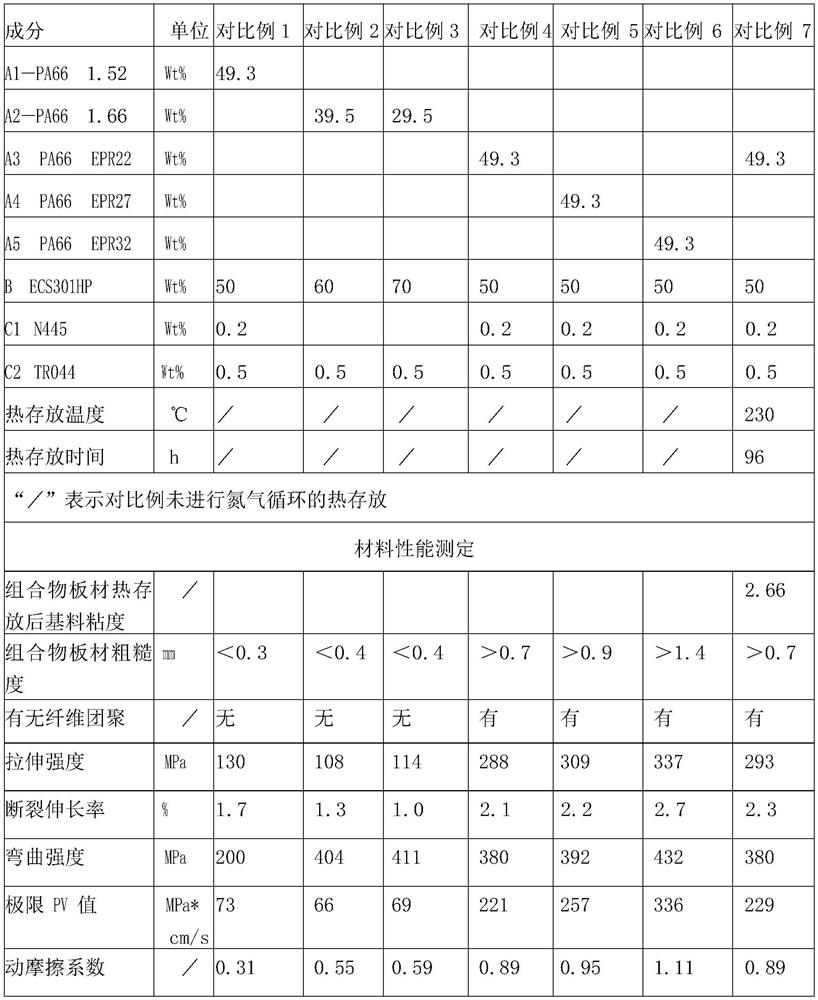

[0035] The specific embodiment of the present invention is described in detail by using the comparison between the technical solution of the invention and the existing technical solution. The compositions of Inventive Examples 1-8 and Comparative Examples 1-7 were prepared by mixing together the ingredients listed below in relative amounts (all expressed in weight fractions). The components A1-A3 in Comparative Examples 1-3 are polyamide 66 resins prepared by the technical solution of the present invention, and the components A in Comparative Examples 4-7 are A3-A5 purchased from the existing market.

[0036] Component A:

Embodiment 1

[0037] A1: PA66-1.52, relative viscosity 1.52, terminal carboxyl group content 86mmol / kg, terminal amino group content 89mmol / kg, see Example 1 for details;

Embodiment 2

[0038] A2: PA66-1.66, relative viscosity 1.66, terminal carboxyl group content 80mmol / kg, terminal amino group content 74mmol / kg, see Example 2 for details;

[0039] A3: PA66, brand EPR22, relative viscosity 2.2, terminal carboxyl group content 72mmol / kg, terminal amino group content 48mmol / kg, purchased from the existing market;

[0040] A4: PA66, grade EPR27, relative viscosity 2.7, purchased from the existing market;

[0041] A5: PA66, grade EPR32, relative viscosity 3.2, purchased from the existing market;

[0042] Component B:

[0043] Glass fiber: brand ECS301HP, diameter 10um, length 4.5mm, purchased from Chongqing International Composite Materials Co., Ltd.

[0044] Component C:

[0045] C1: Antioxidant N445, purchased from Lanxess Special Chemicals, Germany;

[0046] C2: lubricant, stearate, brand TR044, purchased from Structol, Germany.

[0047] Example 1:

[0048] To 0.05m equipped with stirring equipment, partial condenser, condenser, thermometer, dropping fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com