Coal-fired boiler exhaust gas temperature prediction method and system based on LightGBM and random search method

A technology for exhaust gas temperature and coal-fired boilers, applied in the field of coal-fired boilers, can solve the problems that the support vector machine model is not suitable for large sample learning, the neural network model is easy to fall into local minimum values, and is easy to overfit, etc. Excellent generalization ability, fast calculation speed, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

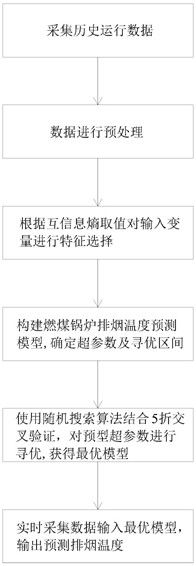

[0091] This embodiment is a method for predicting the exhaust gas temperature of a coal-fired boiler based on LightGBM and random search method. The method is described in detail below with an example. figure 1 shown, including the following steps:

[0092] S1. Collect historical operating data, including coal type and coal quality data, operating status data as input data, and flue gas temperature data as output data. The original sample size of the data is 6000, and the input data collected is as shown in the following table:

[0093] ;

[0094] No. 7, 13, and 15 each have data corresponding to 6 coal mills (feeders), and No. 17 has the data of the secondary air door opening of three layers of burners, so the total number of input parameters is 40.

[0095] The collected output data is the exhaust gas temperature data, in °C.

[0096] The collected data format is:

[0097] ,

[0098] ,

[0099] ,

[0100] in, X i Represents a group of input parameter data, a...

Embodiment 2

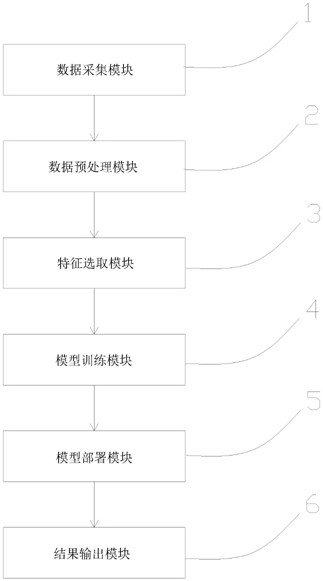

[0220] This embodiment is a coal-fired boiler exhaust gas temperature prediction system based on LightGBM and random search method, which is dedicated to the method in Embodiment 1. The system structure includes a data acquisition module, a data preprocessing module, a feature selection module, a model training module, a model deployment module and a result output module connected in sequence.

[0221] The data acquisition module collects historical operation data, including coal type and coal quality data as input data, operating status data, and exhaust gas temperature data as output data;

[0222] Data preprocessing module, which preprocesses data, including deleting zero and missing data points, detecting and cleaning data outliers, and normalizing data;

[0223] The feature selection module performs feature selection on the input variables according to the value of mutual information entropy for the preprocessed data, and obtains the input and output data matrix of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com