Pathological sample preparation and desoxyribonucleic acid quantitative staining instrument and use method thereof

A deoxyribonucleic acid and staining instrument technology, applied in the field of medical machinery, can solve the problems of troublesome operation and increase the cost of labor, and achieve the effect of avoiding pollution and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

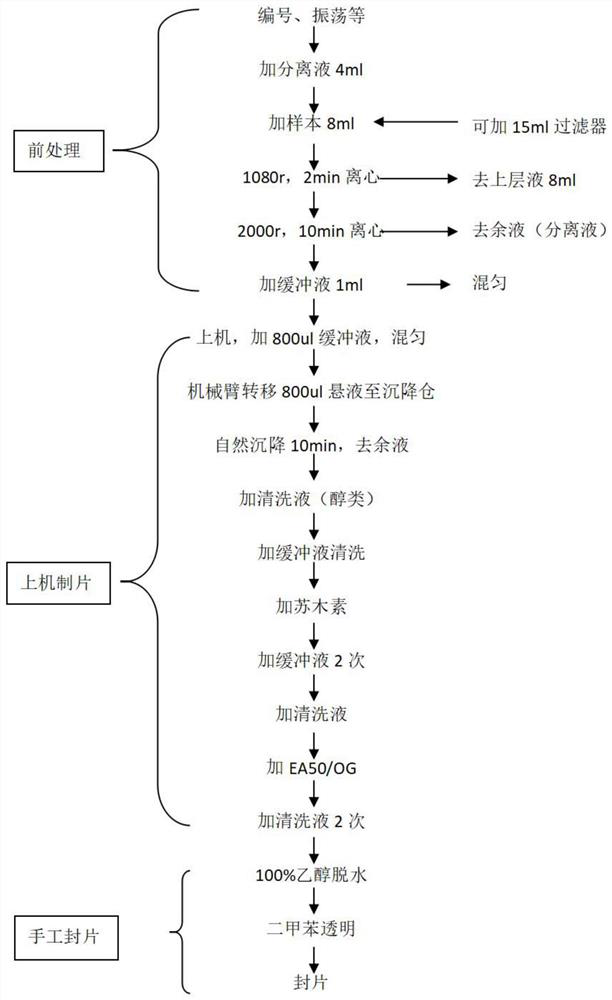

[0043] Mode 1: Make 1 slide + Pasteur staining (gradient centrifugation + automatic transfer + natural sedimentation + Pasteur staining)

[0044] Pre-treatment: specimen, slide number, shake the specimen; add 4ml of separation solution to the centrifuge tube, add 8ml of specimen; centrifuge at 1080r for 2min, discard 8ml of the upper separation solution; centrifuge again for 2000r, 10min, discard the remaining liquid; add 1ml of buffer liquid, and shake to mix.

[0045] Loading the tablet: Go on the machine, set the machine working temperature to 25°C, add 800ul buffer, and mix for N times; transfer 800ul of the suspension to the sedimentation chamber with the robotic arm, settle for 10 minutes, and aspirate and discard the waste liquid from the sedimentation chamber; wash 3 with 1ml of cleaning solution For the last time, let the washing solution stand for 1 minute, then aspirate and discard the washing solution; rinse 3 times with 1 ml buffer, aspirate and discard the buffer...

Embodiment 2

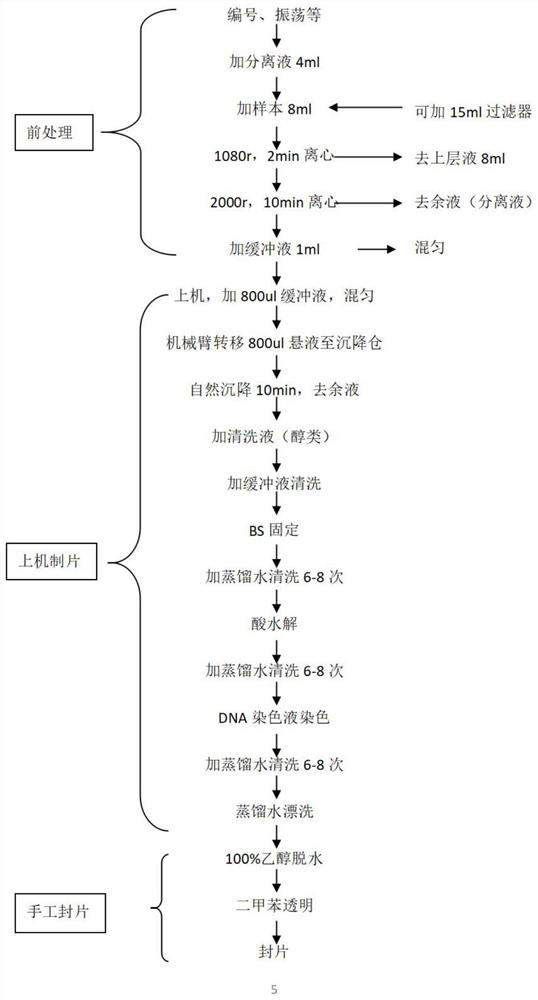

[0049] Mode 2: Making 2 slides + DNA staining (gradient centrifugation + automatic transfer + natural sedimentation + DNA staining)

[0050] Pre-treatment: specimen, slide number, shake the specimen; add 4ml of separation solution to the centrifuge tube, add 8ml of specimen; centrifuge at 1080r for 2min, discard 8ml of the upper separation solution; centrifuge again for 2000r, 10min, discard the remaining liquid; add 1ml of buffer liquid, and shake to mix.

[0051]Loading the tablet: Go to the machine, set the machine working temperature to 35°C, add 800ul buffer, and mix for N times; transfer 800ul of the suspension to sedimentation chamber 1 and sedimentation chamber 2, and settle for 10 minutes; suction and discard sedimentation chamber 1, sedimentation Warehouse 2 waste solution; add 1ml buffer, aspirate and discard; wash 3 times with 1ml washing solution, and let the last washing solution stand for 1 minute. Settling bin 2 sucks and discards the cleaning solution, settli...

Embodiment 3

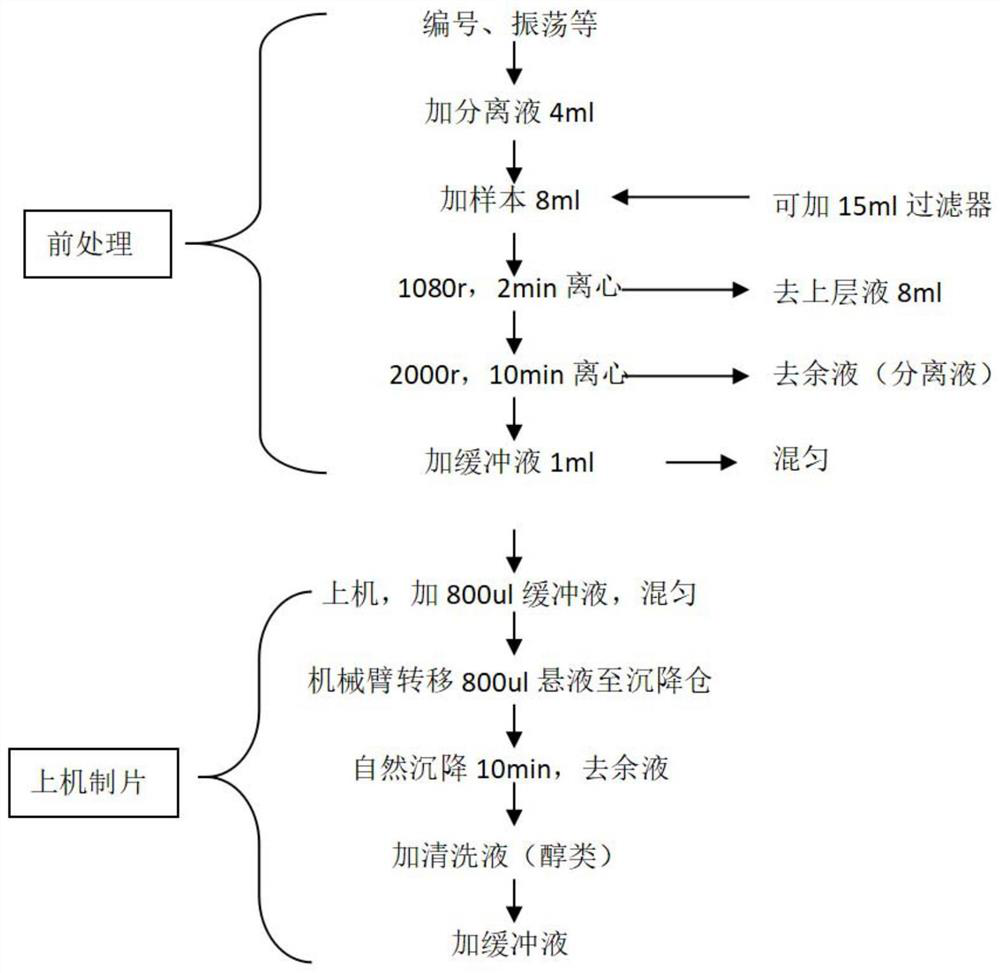

[0056] Mode 3: Make 2 slices separately (gradient centrifugation + automatic transfer + natural sedimentation)

[0057] Pretreatment: Specimen, slide number, shake the specimen; add 4ml of separation solution to the centrifuge tube, add 8ml of specimen; centrifuge at 1080r for 2min, discard 8ml of the supernatant separation solution; centrifuge again for 2000r, 10min, discard the remaining liquid; add 1ml of buffer liquid, and shake to mix.

[0058] Loading the tablet: put on the machine, add 800ul buffer, mix N times; transfer 800ul suspension to sedimentation chamber 1, sedimentation chamber 2, and settle for 10 minutes; suction and discard the waste liquid of sedimentation chamber 1 and sedimentation chamber 2; add 1 ml Buffer, aspirated and discarded; 1 ml of washing solution was washed 3 times, the last washing solution was allowed to stand for 1 minute, and the washing solution was aspirated and discarded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com