Shallow hydrogen gas appliance

A gas appliance, hydrogen technology, applied in the direction of burner, hydrogen technology, combustion type, etc., can solve the problems of reduced material toughness, material performance deterioration, fatigue crack growth rate increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

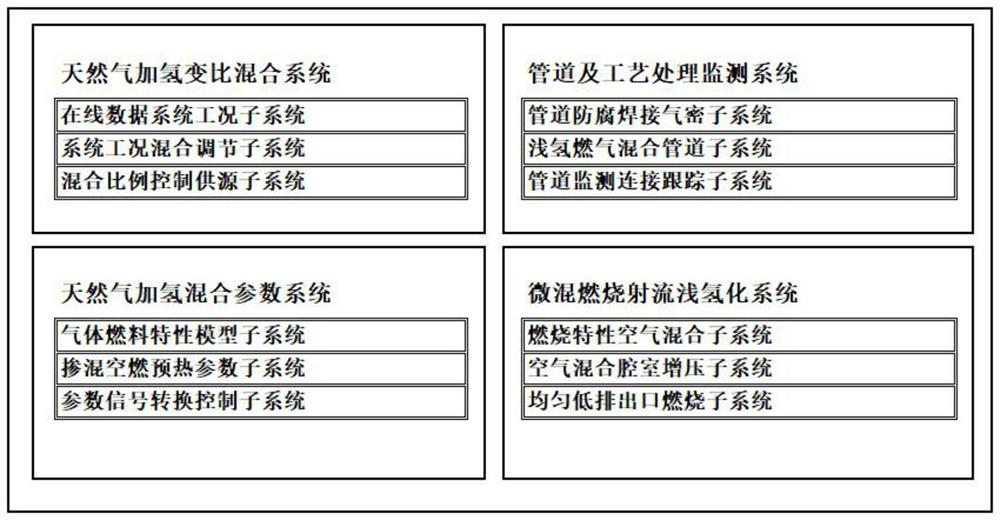

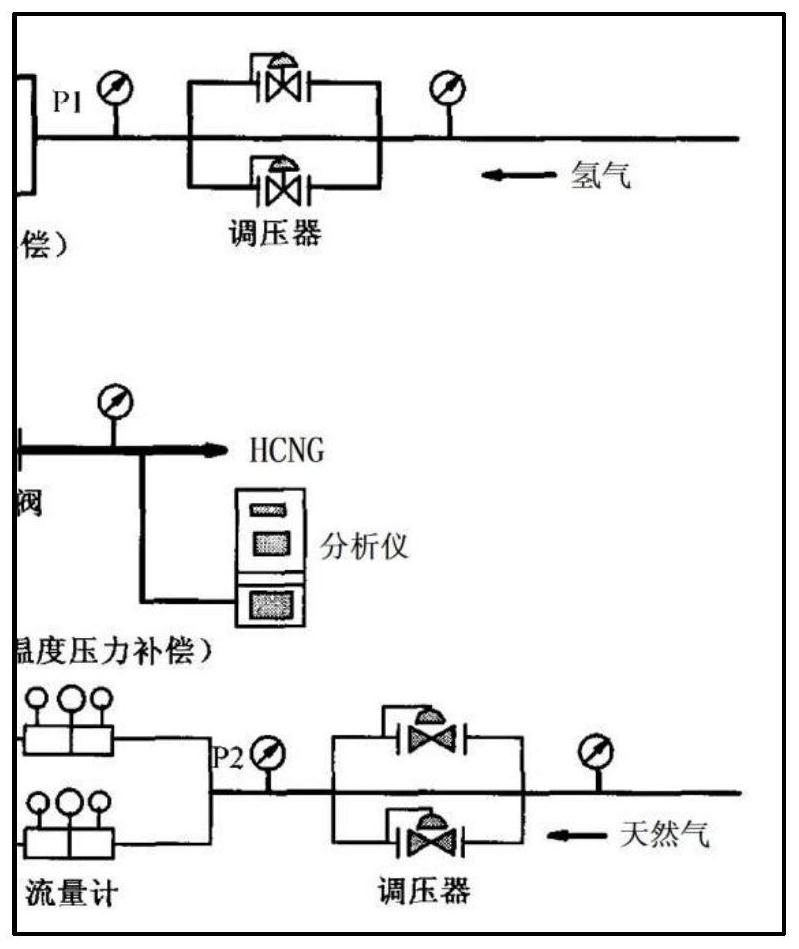

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art can implement it with reference to the description; Figure 1-3 As shown, the present invention provides a shallow hydrogen gas appliance, comprising:

[0053] Natural gas hydrogenation variable ratio mixing system, through the use of online data to control the mixing, according to the change of system operating conditions, control the mixing ratio of natural gas and hydrogen, and provide shallow hydrogen natural gas mixed gas with corresponding hydrogen mixing ratio;

[0054] Pipeline and process treatment monitoring system, through the process optimization and gas sampling monitoring on the shallow hydrogen natural gas mixed gas pipeline and the pipeline welding parts, to monitor and track the status of the pipeline and welding parts;

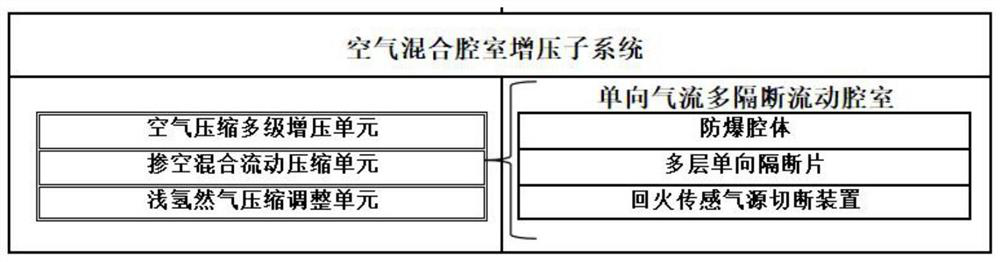

[0055] The natural gas hydrogenation mixing parameter system controls the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com