Polyurethane self-skinning foam as well as preparation method and application thereof

A self-skinning, polyurethane technology, applied in the field of polyurethane self-skinning foam and its preparation, can solve problems such as large odor, and achieve the effects of skin comfort, appearance improvement, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

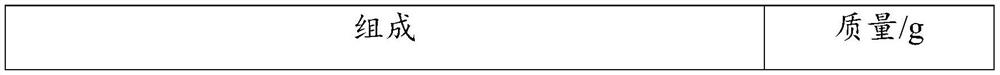

[0063] The present embodiment provides a kind of polyurethane self-skin foam, and its raw material composition is shown in the following table:

[0064]

[0065]

[0066] The preparation method of the above-mentioned polyurethane self-skin foam, comprising,

[0067] (1) uniformly mixing polyether-polysiloxane copolymer, amino polyether polyol, polyurea polymer polyol, water and silica to obtain a premix;

[0068] (2) adjusting the temperature of the premix to be 35°C, and mixing it with the carbodiimide-modified isocyanate at 25°C to obtain a mixture;

[0069] (3) Quickly pour the mixture into the mold, and control the mold temperature to be 30 ° C for molding, demould after molding, control the overfill factor to be 48% during pouring, and the shortest demoulding time is 2.1min. Among them, the shortest demoulding time Time refers to the shortest time until the mixture is poured into the mold, the mixture is formed, and the product is taken out of the mold without defo...

Embodiment 2

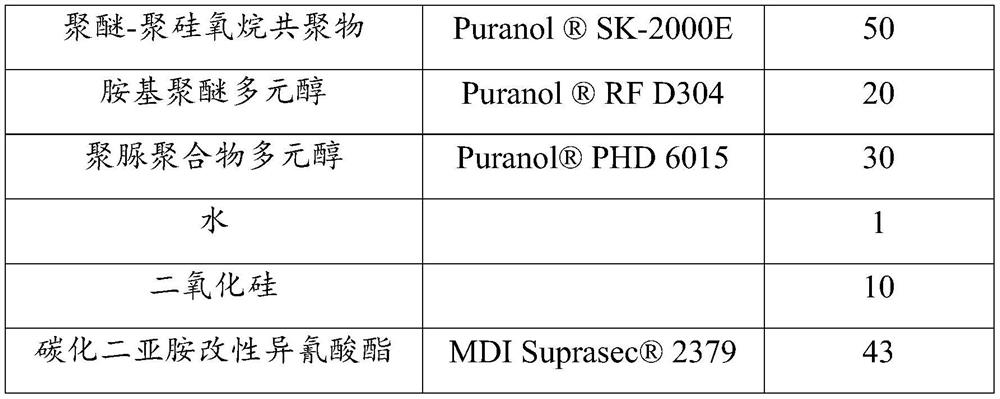

[0072] The present embodiment provides a kind of polyurethane self-skin foam, and its raw material composition is shown in the following table:

[0073]

[0074]

[0075] The preparation method of the above-mentioned polyurethane self-skin foam, comprising,

[0076] (1) uniformly mixing polyether-polysiloxane copolymer, amine-based polyether polyol, polyurea polymer polyol, water and aluminum hydroxide to obtain a premix;

[0077] (2) adjusting the temperature of the premix to be 35°C, and mixing it with the carbodiimide-modified isocyanate at 25°C to obtain a mixture;

[0078] (3) Quickly pour the mixture into the mold, and control the mold temperature to 30 ° C for molding, demould after molding, control the overfill factor to be 42% during pouring, and the shortest demoulding time is 3.4min.

[0079] After demoulding, the product was placed at room temperature for 48 hours for aging to obtain polyurethane self-skin foam.

Embodiment 3

[0081] The present embodiment provides a kind of polyurethane self-skin foam, and its raw material composition is shown in the following table:

[0082]

[0083] The preparation method of the above-mentioned polyurethane self-skin foam, comprising,

[0084] (1) uniformly mixing polyether-polysiloxane copolymer, amine-based polyether polyol, polyurea polymer polyol, water and melamine to obtain a premix;

[0085] (2) adjusting the temperature of the premix to be 35°C, and mixing it with the carbodiimide-modified isocyanate of 30°C to obtain a mixture;

[0086] (3) Quickly pour the mixture into the mold, and control the mold temperature to 40 ° C for molding, demould after molding, control the overfill factor to 35% during pouring, and the shortest demoulding time is 5min.

[0087] After demoulding, the product was placed at room temperature for 48 hours for aging to obtain polyurethane self-skin foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com