Production method of biomass gasifier shell plate blank

A production method and gasification furnace technology, applied in the direction of products, educts, chemical industry, etc., to achieve the effects of convenient welding connection, simplified manufacturing, and convenient batch production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

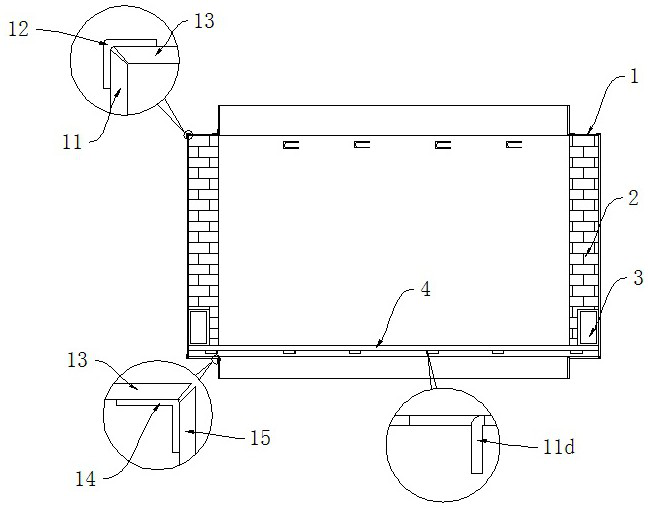

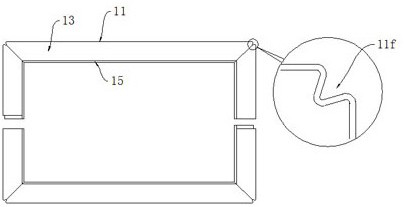

[0035] like Figure 1 to Figure 3 As shown, this embodiment designs a biomass gasifier, which includes an outer casing 1, a refractory brick 2, a cooling water pipe, and a furnace bridge 4 and other mechanisms.

[0036]The outer casing 1 includes four side wall plates with a surrounding rectangle, the upper and lower parts of each side wall plate are respectively provided with transverse plates 13, and the inner side of the transverse plates 13 is provided with a mouth vertical plate 15, and biomass gasification. The inlet of the furnace is a rectangular mouth surrounded by a plurality of mouth vertical plates 15 on the upper part of the side wall plate, and the outlet of the biomass gasifier is a rectangular mouth surrounded by a plurality of mouth vertical plates 15 on the lower part of the side wall plate. Refractory bricks 2 are respectively arranged on the inner side of each side wall plate, and the inner side of the refractory bricks 2 is the furnace cavity. The cooling...

Embodiment 2

[0044] In this embodiment, in order to standardize the production of shell slabs and facilitate the mass production of shell slabs, a method for producing shell slabs of biomass gasifiers is designed.

[0045] The production method includes the following steps:

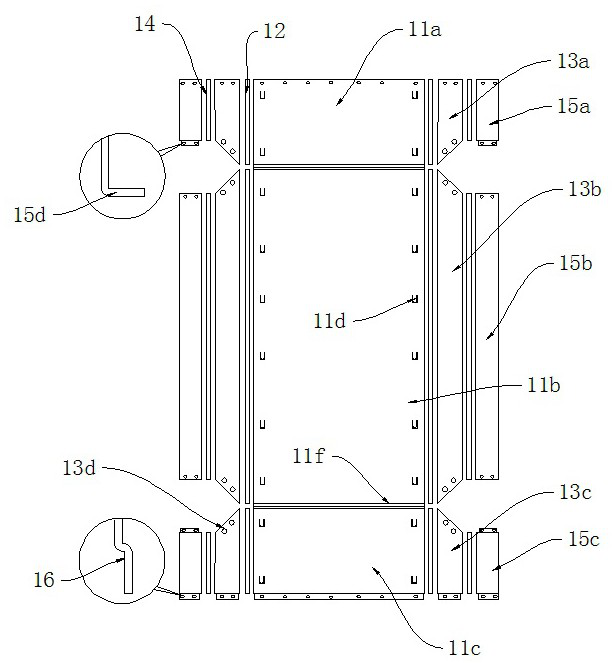

[0046] Step S1 : cutting the metal plate according to the set size to obtain a rectangular main body vertical plate 11 , a trapezoidal transverse plate 13 and a rectangular mouth vertical plate 15 .

[0047] Step S2: Perform edge cutting and edge punching on the main body vertical plate 11, the horizontal plate 13 and the mouth vertical plate 15; in this step, the main body vertical plate 11, the horizontal plate 13 and the mouth vertical plate 15 are mainly processed. Dimension trimming, punching and bending at the same time.

[0048] Specifically, two long sides of the main body vertical plate 11 are respectively punched to form U-shaped holes 11d, and the U-shaped opening of the U-shaped hole 11d faces the short s...

Embodiment 3

[0054] like Figure 1 to Figure 4 As shown, on the basis of the second embodiment, in order to facilitate the relative fixation of the positions of the various components during the welding process in step S4, the present embodiment designs a welding tool frame 5 to be used together.

[0055] The welding tool frame 5 includes two upper and lower frame bodies, and the main body vertical plate 11, the transverse plate 13 and the mouth vertical plate 15 are clamped between the two frame bodies; the front and rear sides of the two frame bodies (refer to Figure 4 , the frame body in the figure is a top view, and the partially enlarged part in the figure is a side view) respectively connected with a hinge 53 and a lock 54; the bending strip is divided into an outer bending strip 14 and an inner bending strip 12; On the left and right sides of the frame body (reference Figure 4 ) are respectively provided with a transverse plate welding groove 56a, the welding connection between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com