Preparation method, product and application of magnetic spinel type adsorbent

A spinel-type, adsorbent technology, applied in separation methods, chemical instruments and methods, and other chemical processes, etc., can solve the problems of adverse effects of environmental protection facilities, high adsorbent prices, and inability to recycle and treat, and achieve the goal of helping The effect of crystal form and crystal size growth control, easy reaction process, and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

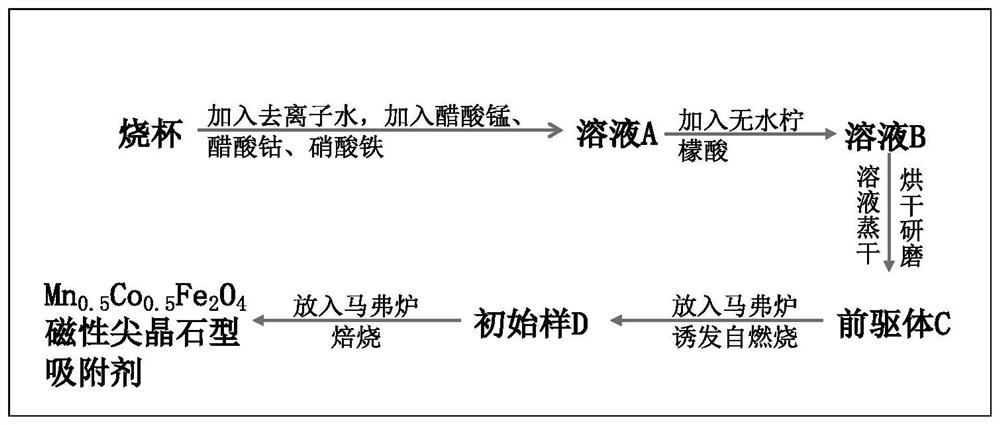

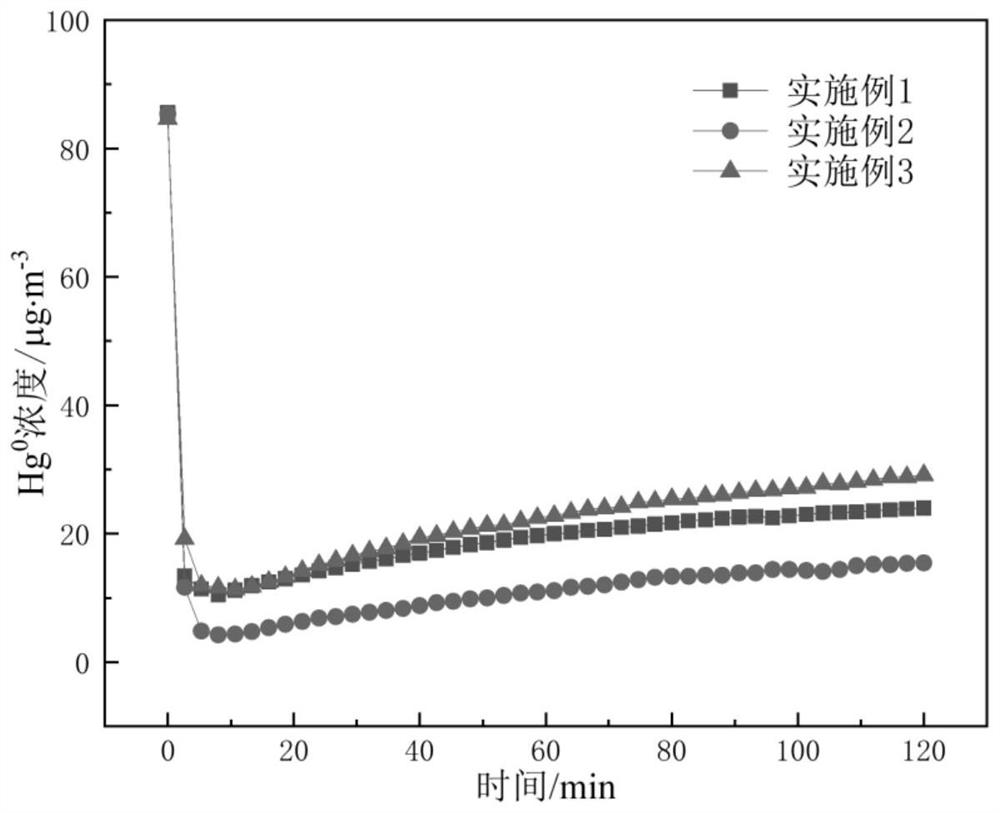

[0031] Embodiment 1: a preparation method of a spinel-type adsorbent for adsorbing gaseous zero-valent mercury, comprising the following steps:

[0032] (a) adding deionized water in the beaker, dissolving manganese acetate, cobalt acetate and ferric nitrate in it according to the stoichiometric ratio Mn:Co:Fe=0.5:0.5:2 to obtain solution A;

[0033] (b) in solution A, add anhydrous citric acid, the stoichiometric ratio of anhydrous citric acid addition and the amount of Fe substance in solution A is 1:0.6, stir to obtain solution B;

[0034] (c) Put the solution B into a constant temperature magnetic stirring water bath, under the conditions of a temperature of 70°C, a time of 4h, and a stirring speed of 250r / min, stir and heat until the solution evaporates to dryness and becomes a wet gel, and then the wet The gel is placed in an oven, dried and ground into powder at a temperature of 100°C and a time of 12h to obtain precursor C;

[0035] (d) put the precursor C into the mu...

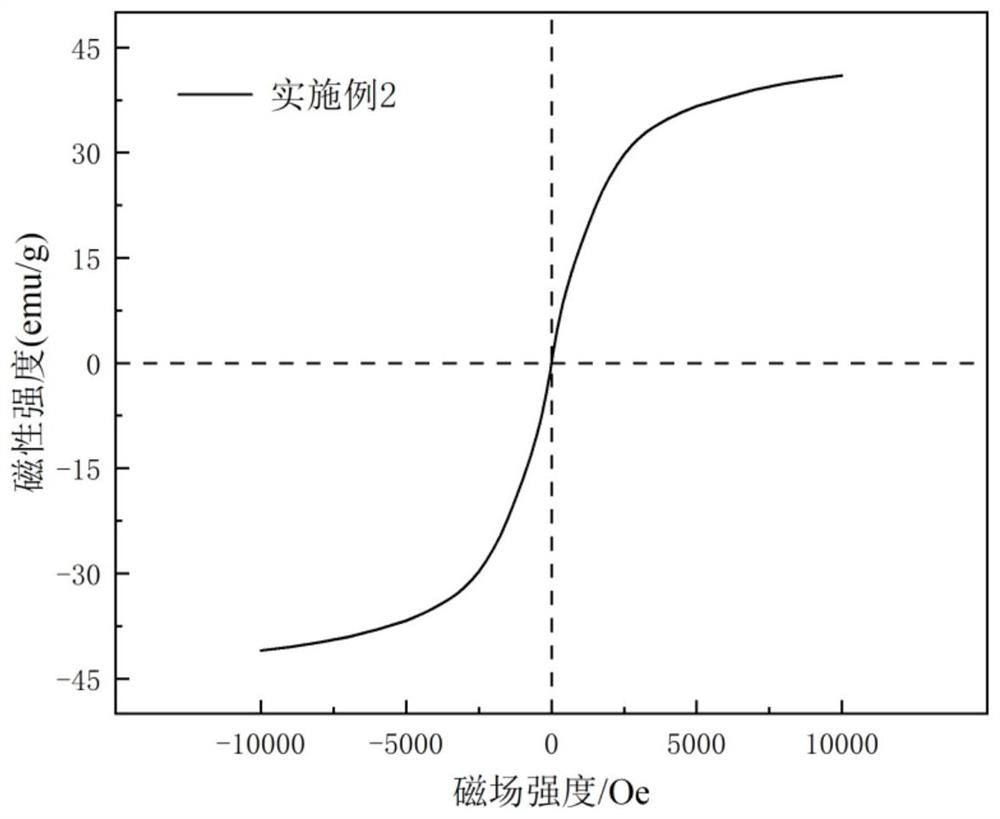

Embodiment 2

[0037] Embodiment 2: a preparation method of a spinel-type adsorbent for adsorbing gaseous zero-valent mercury, comprising the following steps:

[0038] (a) adding deionized water in the beaker, dissolving manganese acetate, cobalt acetate and ferric nitrate in it according to the stoichiometric ratio Mn:Co:Fe=0.5:0.5:2 to obtain solution A;

[0039] (b) in solution A, add anhydrous citric acid, the stoichiometric ratio of anhydrous citric acid addition and the amount of Fe substance in solution A is 1:1.2, stir to obtain solution B;

[0040] (c) Put the solution B in a constant temperature magnetic stirring water bath, under the conditions of a temperature of 80 °C, a time of 2.5 h, and a stirring speed of 350 r / min, stirring and heating until the solution evaporates to dryness and becomes a wet gel, and then the The wet gel was placed in an oven, dried and ground into powder at a temperature of 120°C and a time of 8h to obtain the precursor C;

[0041] (d) put the precursor...

Embodiment 3

[0043] Embodiment 3: a preparation method of a spinel-type adsorbent for adsorbing gaseous zero-valent mercury, comprising the following steps:

[0044](a) adding deionized water in the beaker, dissolving manganese acetate, cobalt acetate and ferric nitrate in it according to the stoichiometric ratio Mn:Co:Fe=0.5:0.5:2 to obtain solution A;

[0045] (b) in solution A, add anhydrous citric acid, the stoichiometric ratio of anhydrous citric acid addition and the amount of Fe substance in solution A is 1:1.8, stir to obtain solution B;

[0046] (c) Put the solution B in a constant temperature magnetic stirring water bath, under the conditions of a temperature of 75°C, a time of 3h, and a stirring speed of 300r / min, stir and heat until the solution evaporates to dryness and becomes a wet gel, and then the wet The gel is placed in an oven, dried and ground into powder at a temperature of 110°C and a time of 10h to obtain the precursor C;

[0047] (d) put the precursor C into the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com