Method for predicting maximum size of second-phase particles of bearing steel based on image recognition

A maximum size, image recognition technology, applied in the field of image processing, can solve the problems of poor reproducibility, low efficiency, and difficulty in finding large-sized second-phase particles, achieving high accuracy, simple operation, and easy calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below with reference to the accompanying drawings and embodiments of the specification.

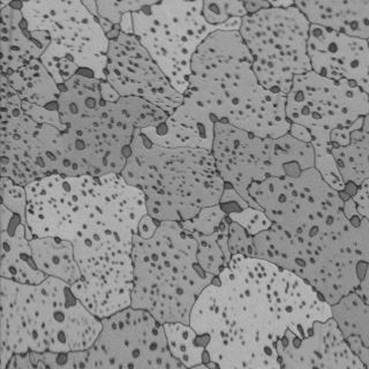

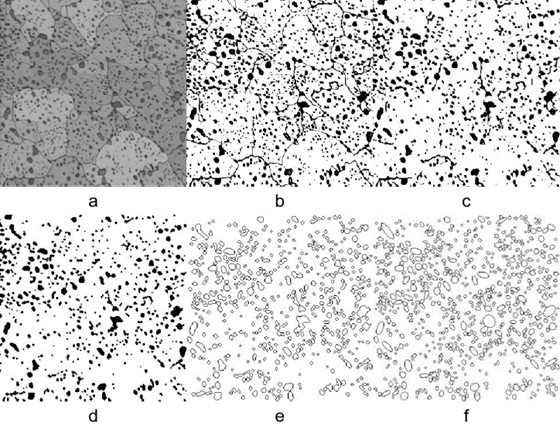

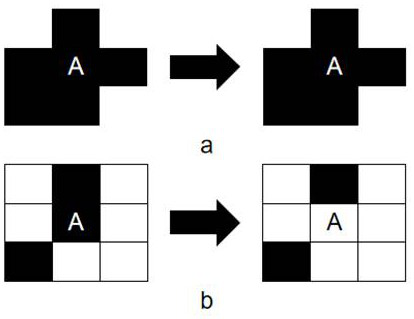

[0052] Take spheroidized annealed GCr15 bearing steel as an example, such as figure 1 shown. The matrix structure of GCr15 bearing steel is ferrite, and a large number of fine second-phase particles of cementite are dispersed on the matrix. The method of batch statistics of bearing steel second phase particle information and prediction of its maximum size based on image recognition technology, the flow chart is as follows Figure 4 As shown, the flow chart of predicting the maximum size of the second phase is as follows Figure 5 shown, the specific method is as follows:

[0053] Step 1. Obtain the micromorphological image of GCr15 bearing steel by scanning electron microscope (SEM).

[0054] Step 2: Image preprocessing, perform grayscale processing on the obtained microscopic topography image, and output a grayscale image, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com