Railway line gantry crane intelligent control system

An intelligent control system, wireless control technology, applied in the direction of comprehensive factory control, road, transportation and packaging, etc., can solve the problems of low operation efficiency, inconvenient use, high cost, etc., to achieve small space occupation, flexible operation and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] An embodiment of the intelligent control system for railway line gantry crane transportation of the present invention specifically includes: a wireless control system, a door crane 100, a lifting platform 200, a first flat car 300 and a second flat car 400 (the first flat car 300 and the second flat car 300 and the second flat car 400). The two flat cars 400 are collectively referred to as rail flat cars). The first flat car 300 is used for transporting the door hanger 100 and the lifting platform 200 , and the second flat car 400 is used for transporting line components. The control objects of the wireless control system are as follows: Figure 8 and 9 As shown, several door hanging devices 100 , several lifting platforms 200 and power devices 43 are included.

[0068] as attached Figure 19 As shown, it is a schematic diagram of the transportation structure of the rail line gantry hoisting system. The door hoisting device 100 and the lifting platform 200 are both a...

Embodiment 2

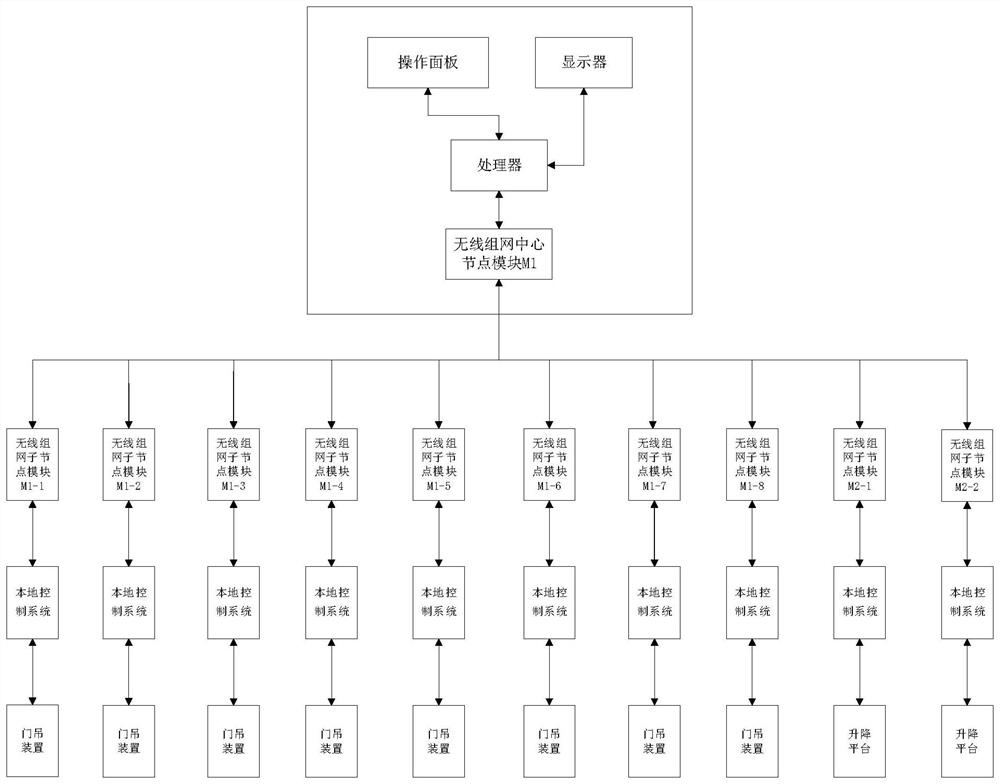

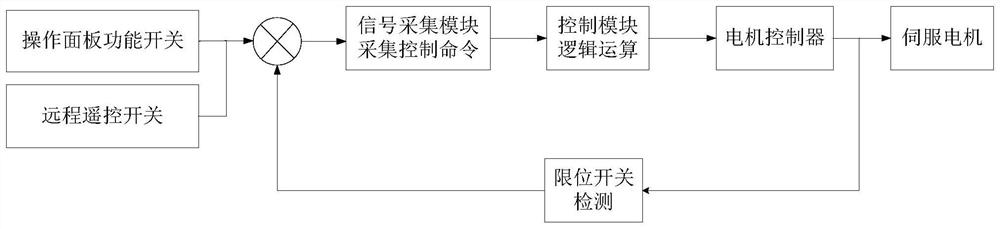

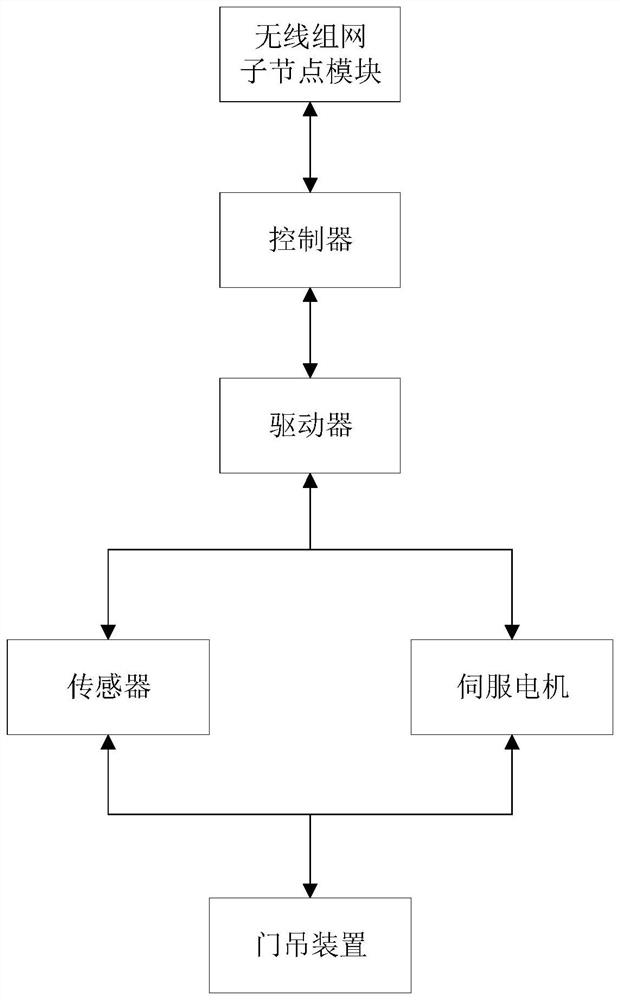

[0087] An embodiment of a wireless control system applied to the railway line gantry hoisting intelligent control system described in Embodiment 1, wherein the door hanging device 100 and the lifting platform 200 are the control objects of the track line gantry hoisting wireless control system. as attached figure 1 , 3 As shown in and 4, the wireless control system for rail line gantry hoisting specifically includes: a wireless control device, a door crane control system and a lifting platform control system, and the wireless control device includes a display, a control panel, a processor and a wireless networking center node module. The door crane control system and the lifting platform control system both include wireless networking sub-node modules and a local control system. The local control system includes controllers, drivers, sensors and servo motors (including hoisting drive motors 12, transverse drive motors 18, traverse drive motor 28, lift drive motor 41, etc.). ...

Embodiment 3

[0112] as attached Figure 20 As shown, an embodiment of the rail line gantry hoisting operation method based on the railway line gantry hoisting intelligent control system of the present invention described in Embodiment 1 specifically includes the following steps:

[0113] S101) The door hanger 100 retracts the left and right legs, and is fixed on the first flat car 300 and transported to the work site, as shown in the attached Figure 21 shown;

[0114] S102) After arriving at the construction site, deploy the door hanging device 100 through the lifting platform 200, the left outrigger and the right outrigger of the door hanging device 100 are extended and supported to the track road surface, and the small outrigger 1 is carried out according to the inclination of the door hanging device 100. The leveling control is used to adjust the level of the truss 4, and the first flat car 300 is withdrawn, as attached Figure 22 shown;

[0115]S103) The door hoisting device 100 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com