High-stability automatic screen printing machine

A high-stability, screen-printing machine technology, used in screen-printing machines, printing machines, rotary printing machines, etc., can solve the problems affecting capacitor capacity, uniform force, and screen printing machine deviations, etc., to improve lifting stability, Avoid uneven force, avoid overheating deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

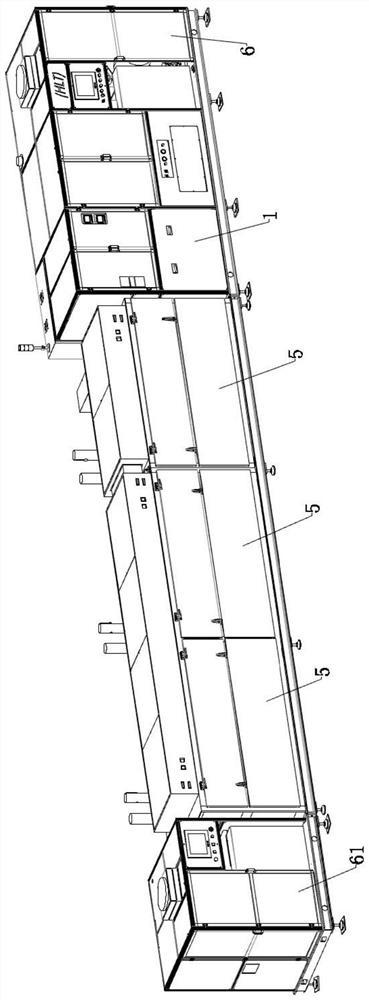

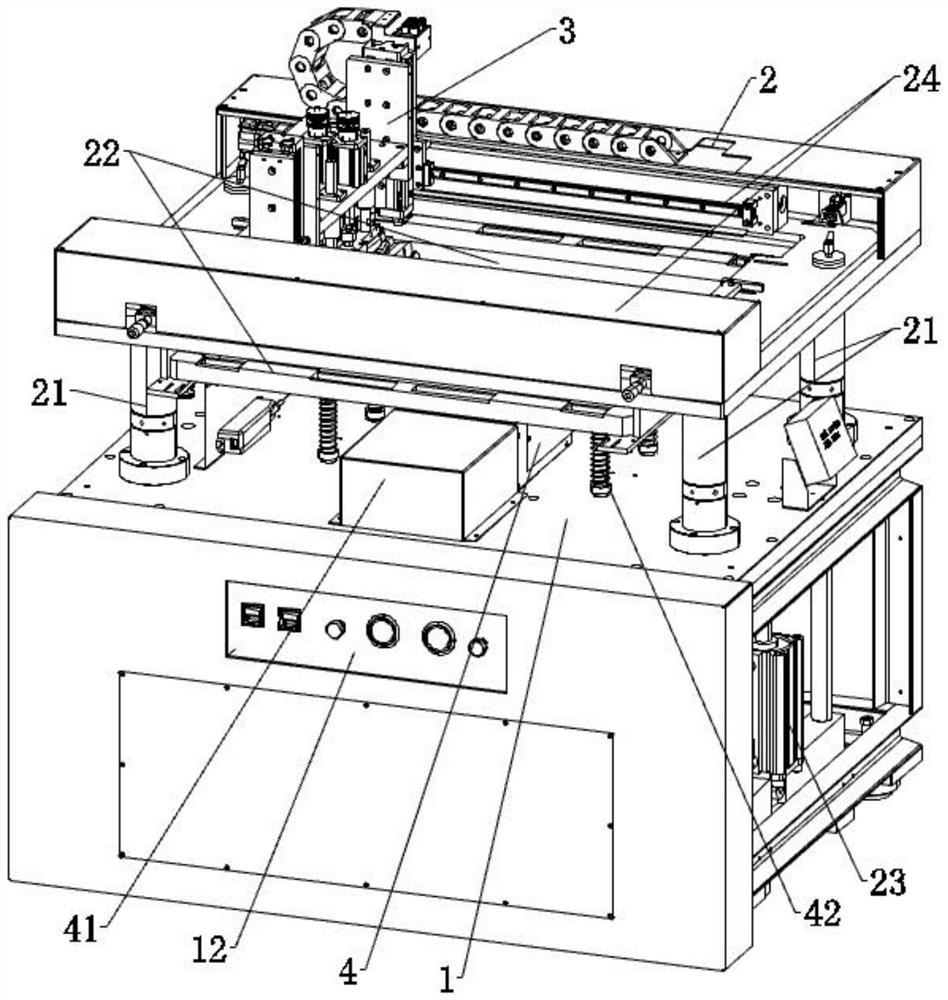

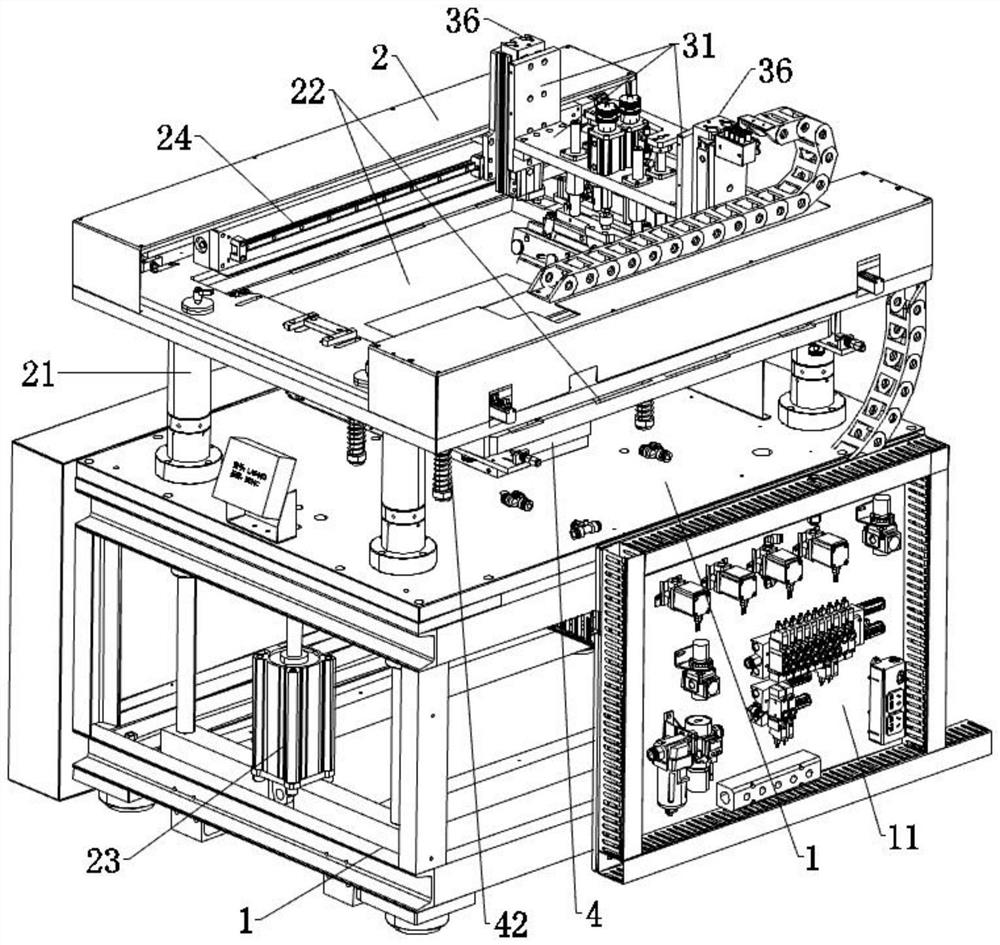

[0050] see Figures 1 to 10 As shown, the present invention provides a technical solution: a high-stability automatic screen printing machine, comprising:

[0051] Workbench 1, printing platform 2, printing mechanism 3, suction plate 4, oven 5, unwinding mechanism 6 and winding mechanism 61;

[0052] The workbench 1 is a horizontal reference platform, and the workbench 1 is also provided with a controller 11 and an operation panel 12;

[0053] The printing platform 2 is an integral structure platform with two rails 24, the printing platform 2 is horizontally established above the workbench 1, and a platform lifting cylinder 23 is arranged below the printing platform 2, and the printing platform 2 passes through. The platform lifting cylinder 23 can be vertically lifted and mounted on the worktable 1. The two rails 24 are parallel to each other and are arranged horizontally. A printing template 22 is also provided on the platform 2, and the printing template 22 is arranged di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com