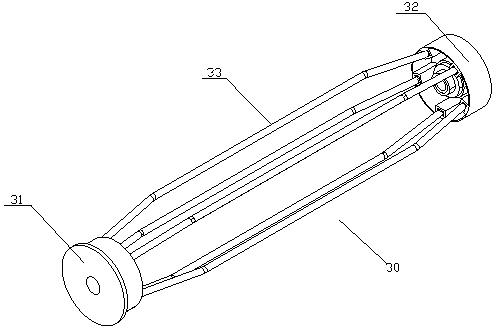

Roller brush support automatic assembly process method based on visual positioning

An automatic assembly and visual positioning technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of high assembly cost and low assembly efficiency, and achieve accurate and efficient alignment work, saving energy consumption, and efficient assembly work. and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

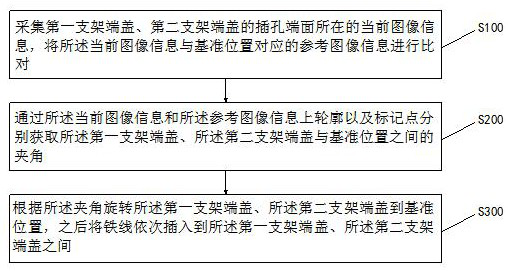

[0041] like figure 2 As shown, the embodiment of the present invention provides a process method for automatic assembly of roller brushes based on visual positioning, and the method includes:

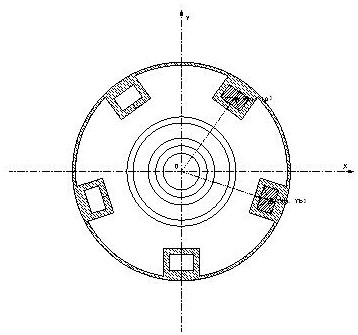

[0042] S100. Collect current image information where the end faces of the jacks of the first support end cover and the second support end cover are located, and compare the current image information with the reference image information corresponding to the reference position;

[0043] Wherein, set the reference positions of the first bracket end caps and the second bracket end caps on the assembly station, and collect and store the reference positions corresponding to the first bracket end caps and the second bracket end caps. Reference image information.

[0044]Wherein, to detect whether the first bracket end cap and the second bracket end cap have reached the assembly station, the first bracket end cap and the second bracket end cap are arranged oppositely at the assembly station. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com