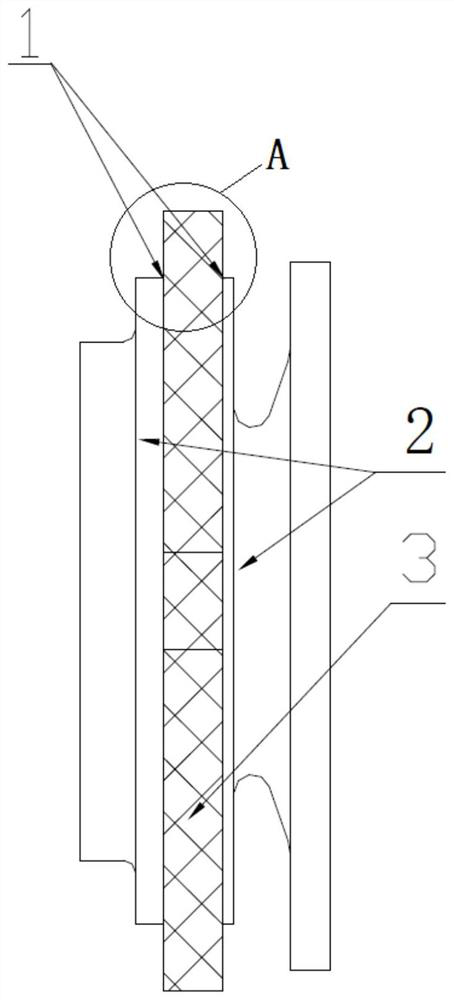

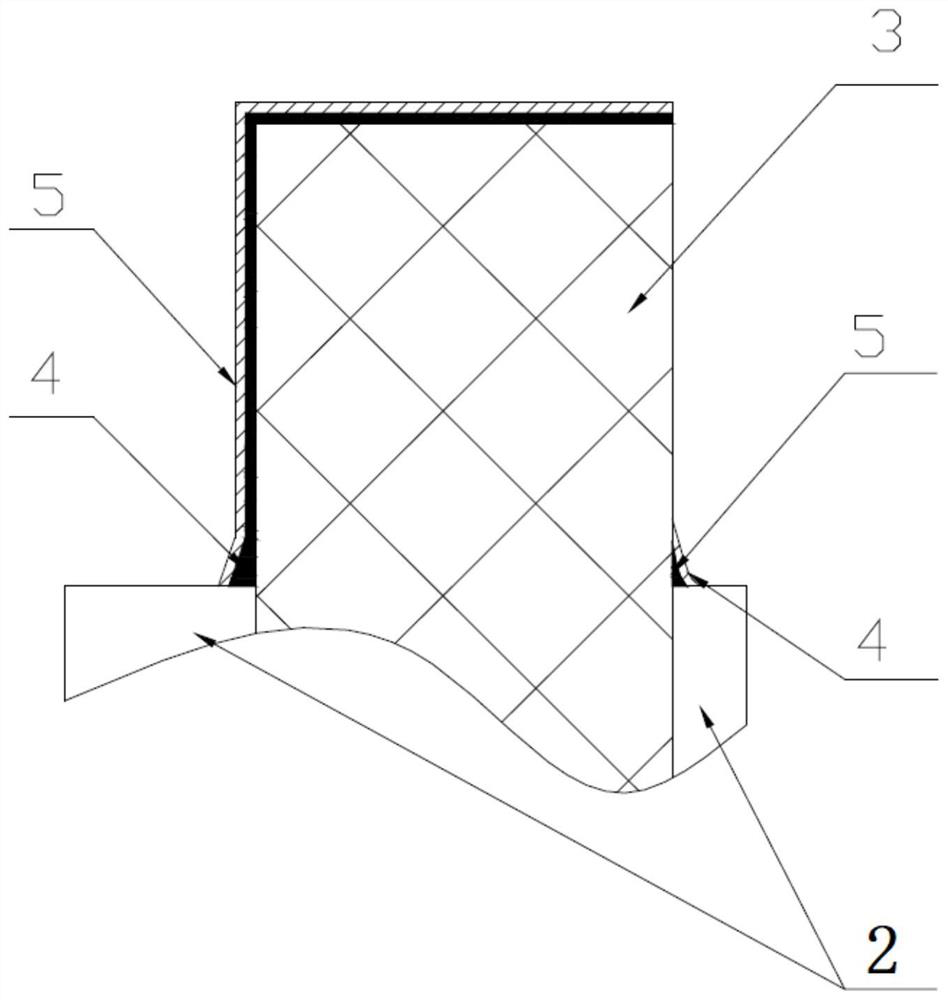

Method for solving layering of wax mold and mold core of precision casting

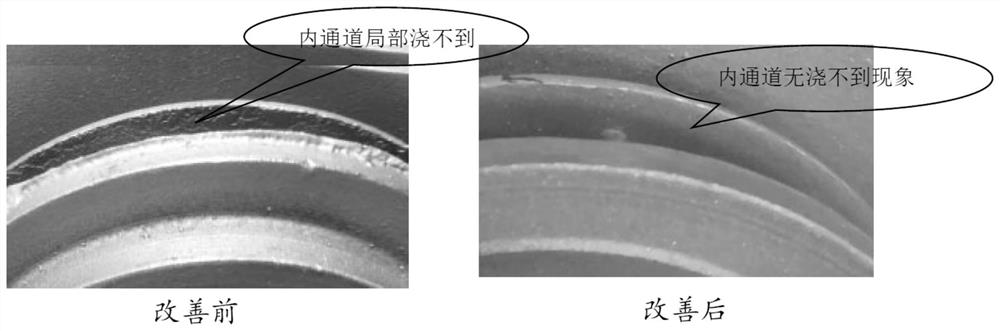

A precision casting and wax mold technology, which is applied in the field of precision casting, can solve the problems of casting inner passages not pouring, and achieve the effects of reducing raw material and labor waste, saving production costs, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment takes a radial vortex device with a venturi as an example, and the method for improving the surface quality of the inner channel of the casting is carried out according to the following steps:

[0045] Step 1. Use a conventional method to manufacture a ceramic core.

[0046] Step 2. Use conventional methods to press the wax mold. Among them, injection pressure: 10bar; pressure holding time: 10s.

[0047] Step 3. Perform X-ray inspection on the wax model; trim the wax model.

[0048] Step 4. Prepare free end paint, including the following steps:

[0049] Step 4.1, soak 10 g of malachite green in 500 ml of acetone for 24 hours to obtain a saturated malachite green acetone solution.

[0050]During use, acetone was added to the saturated malachite green acetone solution containing malachite green crystals. When there are no malachite green crystals in the acetone containing malachite green, 10 g of malachite green should be added to the bottle to make th...

Embodiment 2

[0063] This embodiment takes the radial vortex device with a venturi tube in a scientific research machine as an example, and the method for improving the surface quality of the inner channel of the casting is carried out according to the following steps:

[0064] Step 1. Use a conventional method to manufacture a ceramic core.

[0065] Step 2. Use conventional methods to press the wax mold. Among them, injection pressure: 5bar; pressure holding time: 15s.

[0066] Step 3. Perform X-ray inspection on the wax model; trim the wax model.

[0067] Step 4. Prepare free end paint, including the following steps:

[0068] Step 4.1, soak 12 g of malachite green in 500 ml of acetone for 24 hours to obtain a saturated malachite green acetone solution.

[0069] During use, acetone was added to the saturated malachite green acetone solution containing malachite green crystals. When there are no malachite green crystals in the acetone containing malachite green, 12 g of left malachite g...

Embodiment 3

[0081] In this embodiment, a radial vortex device of a certain machine is taken as an example, and the method for improving the surface quality of the inner channel of the casting is carried out according to the following steps:

[0082] Step 1. Use a conventional method to manufacture a ceramic core.

[0083] Step 2. Use conventional methods to press the wax mold. Among them, injection pressure: 8bar; pressure holding time: 10s

[0084] Step 3, trim the wax model.

[0085] Step 4. Prepare free end paint, including the following steps:

[0086] Step 4.1, soak 11 g of malachite green in 500 ml of acetone for 24 hours to obtain a saturated malachite green acetone solution.

[0087] During use, acetone was added to the saturated malachite green acetone solution containing malachite green crystals. When there are no malachite green crystals in the acetone containing malachite green, 11 g of malachite green should be added to the bottle to make the malachite green in the aceton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com