Anti-photolysis suspending agent and preparation method thereof

A suspending agent and photolysis technology, applied in botany equipment and methods, fungicides, biocides, etc., can solve the problems of unfavorable industrial mass production, high energy consumption, high cost, and high cost, and achieve excellent photostability, light Small degradation rate, good antibacterial and bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

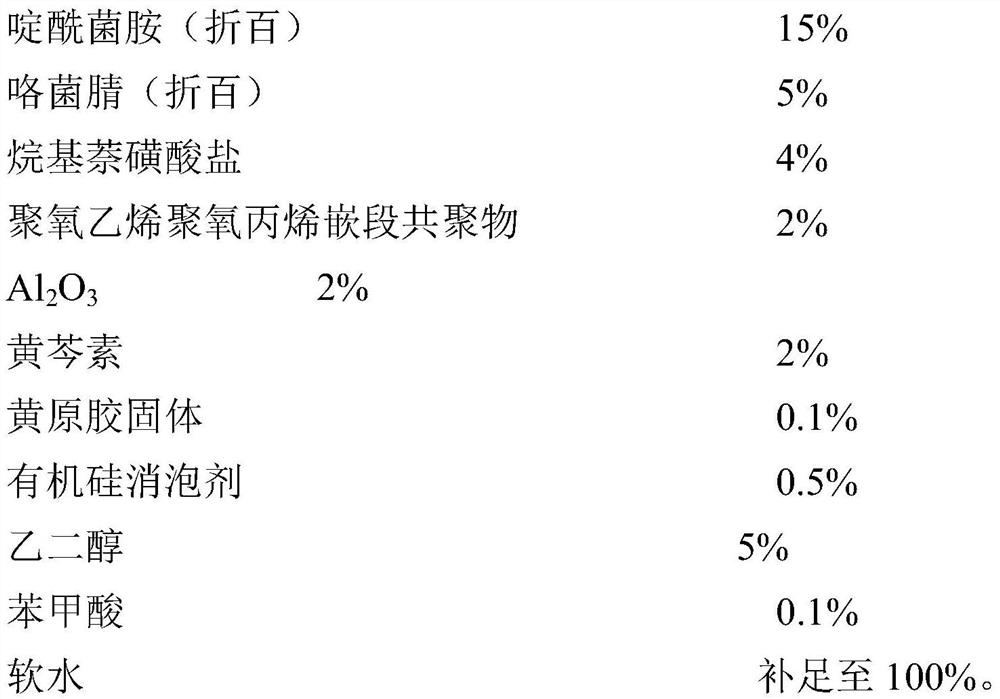

[0053] This embodiment provides a photolysis-resistant 20% boscalid-fludioxonil suspending agent, and its preparation raw materials include the following components by mass percentage:

[0054]

[0055] Prepare a certain concentration of xanthan gum aqueous solution, add enough ethylene glycol and soft water according to the formula ratio, add xanthan gum while cutting, and cut for about 30min to obtain xanthan gum aqueous solution; put in the specified amount of soft water, alkyl group in sequence Naphthalene sulfonate, polyoxyethylene polyoxypropylene block copolymer, silicone defoamer, sheared for 3 min. After shearing, add the original drug (boscalid, fludioxonil), Al 2 O 3 , benzoic acid and baicalein, continue to shear for 15min when there is no agglomeration and floating material, and sand grinding after the shearing is completed. After sanding for a certain period of time, take a sample to detect the particle size, and stop sanding after the particle size is quali...

Embodiment 2

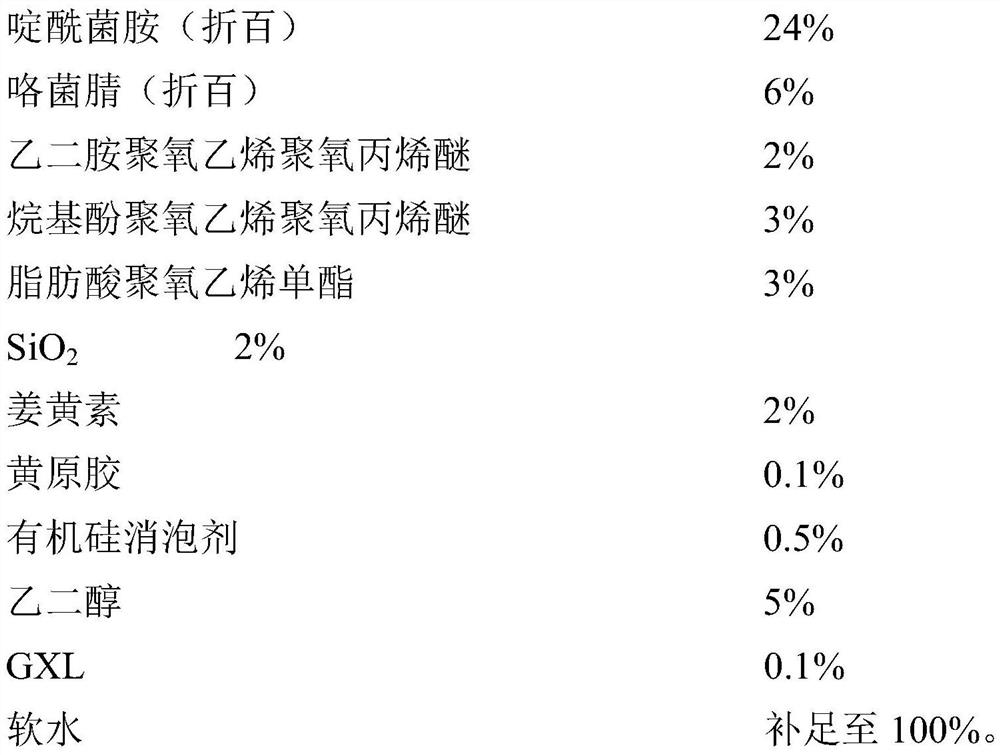

[0058] The present embodiment provides a photolysis-resistant 30% boscalid·fludioxonil suspension agent, and the preparation raw materials include the following components by mass percentage:

[0059]

[0060] Prepare a certain concentration of xanthan gum aqueous solution, add a sufficient amount of ethylene glycol, soft water and GXL according to the formula ratio, add xanthan gum while cutting, and cut for about 30min to obtain the xanthan gum aqueous solution and put it into the specified amount of soft water, ethyl acetate Diamine polyoxyethylene polyoxypropylene ether, alkylphenol polyoxyethylene polyoxypropylene ether, fatty acid polyoxyethylene monoester, silicone defoamer, shear for 3 min. After shearing, add the original drug (boscalid, fludioxonil), SiO 2 And curcumin, continue to cut for 15min when there is no agglomeration and floating material, sand grinding after cutting. After sanding for a certain period of time, take a sample to detect the particle size, ...

Embodiment 3

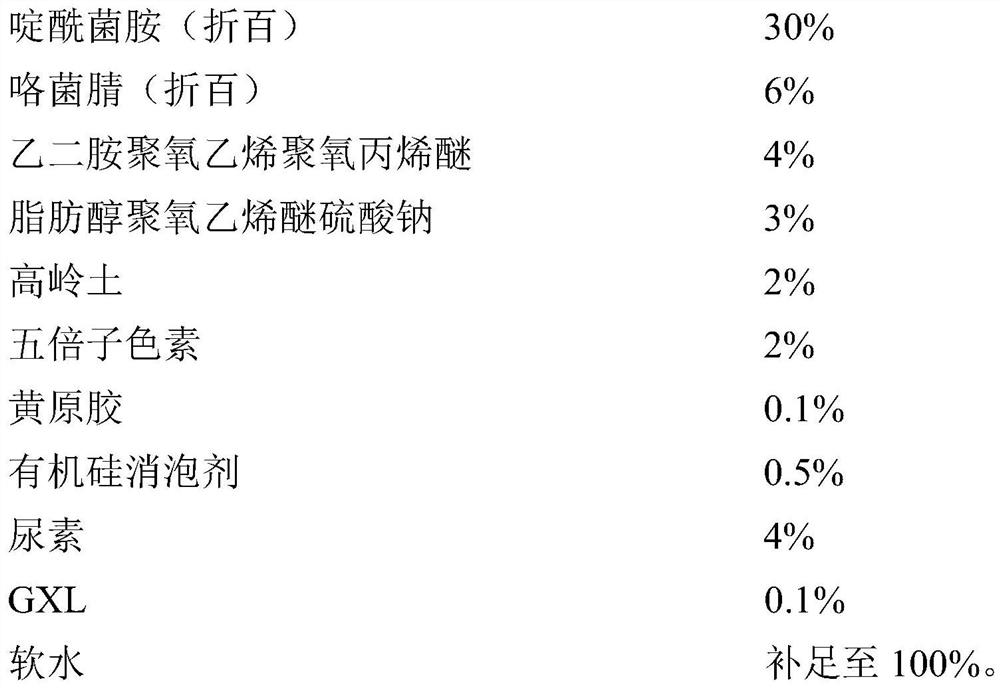

[0063] The present embodiment provides a photolysis-resistant 36% boscalid-fludioxonil suspending agent, and its preparation raw materials include the following components by mass percentage:

[0064]

[0065] Prepare a certain concentration of xanthan gum aqueous solution, add enough soft water and GXL according to the formula ratio, add xanthan gum while cutting, and cut for about 30min to obtain xanthan gum aqueous solution. The specified amount of soft water, ethylenediamine polyoxyethylene polyoxypropylene ether, fatty alcohol polyoxyethylene ether sodium sulfate, and silicone defoamer were added in sequence, and sheared for 3 minutes. After shearing, put in the original drug (boscalid, fludioxonil), urea, kaolin and gall pigment, continue shearing for 15min when there is no agglomeration and floating material, and sand grinding after shearing is completed. After sanding for a certain period of time, take a sample to detect the particle size, and stop sanding after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com