Steel for 7Ni and production method thereof

A production method and molten steel technology, applied in the field of iron and steel production, can solve problems such as high cost and waste, and achieve the effects of reducing manufacturing costs, improving cleanliness, and avoiding secondary oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

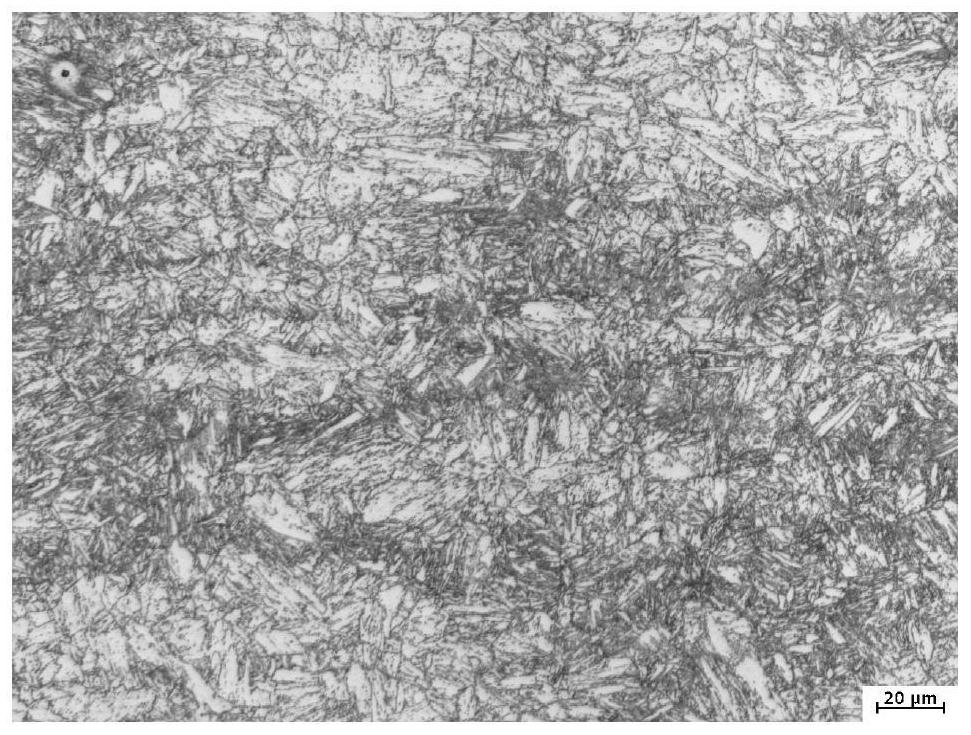

Image

Examples

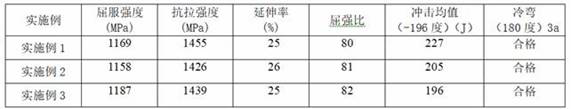

Embodiment 1

[0028] The chemical composition and mass percentage of a 7Ni steel provided in this embodiment are as follows: C: 0.043%, Si: 0.16%, Mn: 0.79%, P: 0.003%, S: 0.0011%, Nb: 0.0030% (residual ), V: 0.002% (residual), Ti: 0.002% (residual), Ni: 7.1%, Cr: 0.02%, Mo: 0.23%, Cu: 0.030%, Al: 0.029%, Mg: 0.0017%, N: 0.0036%, H: 0.00017%, the balance is Fe and inevitable impurities.

[0029] The preparation method includes the following steps:

[0030] S1. The molten iron is desulfurized and sent to the converter for smelting, and the top-bottom re-blowing process is used for smelting. The nickel-molybdenum alloy is added to the converter together with the scrap, and is included in the weight of the scrap. The oxygen is supplied to 80% for slag dumping. The smelting end temperature is 1602 ° C, and the composition meets the requirements carry out the tapping operation;

[0031] S2. The molten steel is sent to refining for deoxidation, alloying and desulfurization operations. After the...

Embodiment 2

[0038]The chemical composition and mass percentage of a 7Ni steel provided in this embodiment are as follows: C: 0.0430%, Si: 0.09%, Mn: 0.779%, P: 0.002%, S: 0.0012%, Nb: 0.0020% (residual ), V: 0.002% (residual), Ti: 0.003% (residual), Ni: 6.96%, Cr: 0.02%, Mo: 0.21%, Cu: 0.010%, Al: 0.038%, Mg: 0.0014%, N: 0.0046%, H: 0.00017%, the balance is Fe and inevitable impurities.

[0039] The preparation method includes the following steps:

[0040] S1. The molten iron is desulfurized and sent to the converter for smelting. The top-bottom re-blowing process is used for smelting. The nickel-molybdenum alloy is added to the converter together with the scrap, and is included in the weight of the scrap. The oxygen is supplied to 80% for slag dumping. The smelting end temperature is 1586 ° C, and the composition meets the requirements carry out the tapping operation;

[0041] S2. The molten steel is sent to refining for deoxidation, alloying and desulfurization operations. After the c...

Embodiment 3

[0048] The chemical composition and mass percentage of a 7Ni steel provided in this embodiment are as follows: C: 0.056%, Si: 0.260%, Mn: 0.93%, P: 0.002%, S: 0.0013%, Nb: 0.003% (residual ), V: 0.002% (residual), Ti: 0.002% (residual), Ni: 7.3%, Cr:: 0.02%, Mo: 0.29%, Cu: 0.020%, Al: 0.041%, Mg: 0.0016%, N : 0.0036%, H: 0.00011%, and the balance is Fe and inevitable impurities.

[0049] The preparation method includes the following steps:

[0050] S1. The molten iron is desulfurized and sent to the converter for smelting. The top-bottom re-blowing process is used for smelting. The nickel-molybdenum alloy is added to the converter together with the scrap, and is included in the weight of the scrap. The oxygen is supplied to 80% for slag dumping. The smelting end temperature is 1606 ° C, and the composition meets the requirements carry out the tapping operation;

[0051] S2. The molten steel is sent to refining for deoxidation, alloying and desulfurization operations. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com