Polyamide composition and application thereof

A polyamide composition and polyamide technology, applied in the field of LAP, can solve the problems of line profile corrosion, large residual amount, influence on coating adhesion, etc., and achieve the effect of improving product yield, uniform surface lines, and improving overflow plating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13

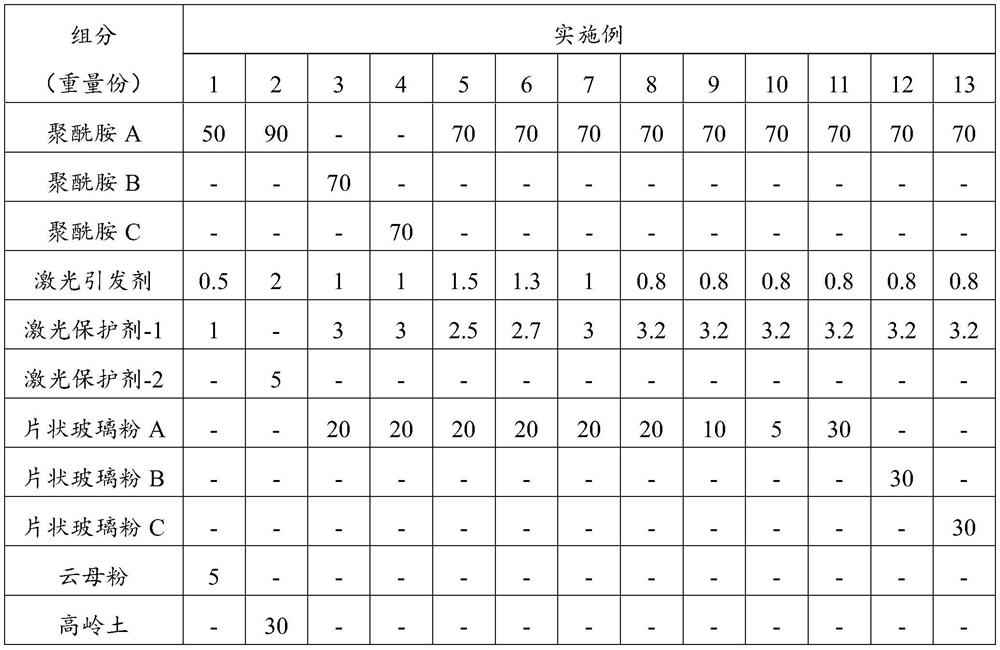

[0044] Embodiments 1 to 13 provide a polyamide composition, the formula of which is shown in Table 1. The preparation method is as follows: after mixing the components uniformly according to the formula, add them into a twin-screw extruder, and melt extrusion and granulation to obtain Polyamide composition. The screw length-diameter ratio of the twin-screw extruder is 48:1, the screw barrel temperature is 200-330°C, and the screw speed is 200-500rpm.

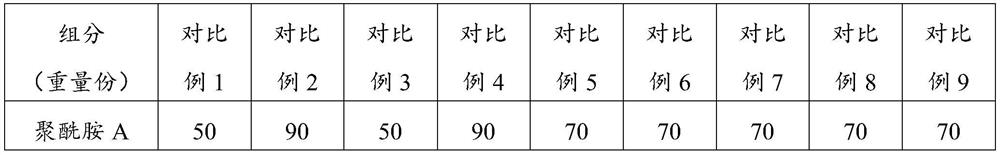

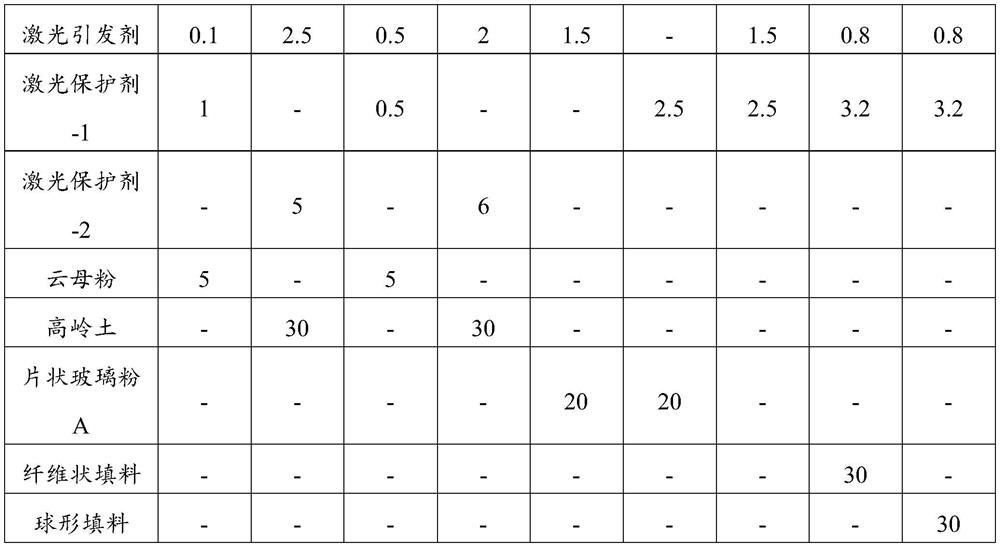

[0045] Comparative Examples 1 to 9 provide a polyamide composition, the formula of which is shown in Table 2, and the preparation method of which refers to the preparation method of Examples 1 to 13.

[0046] Table 1

[0047]

[0048] Note: "-" in the table indicates that this component is not added, the same below.

[0049] Table 2

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com