Preparation and application of graphite phase carbon nitride nanosheet loaded silver monatomic photocatalyst

A graphite-phase carbon nitride and photocatalyst technology, which is applied in the field of photocatalytic materials, can solve problems such as photogenerated carrier recombination, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

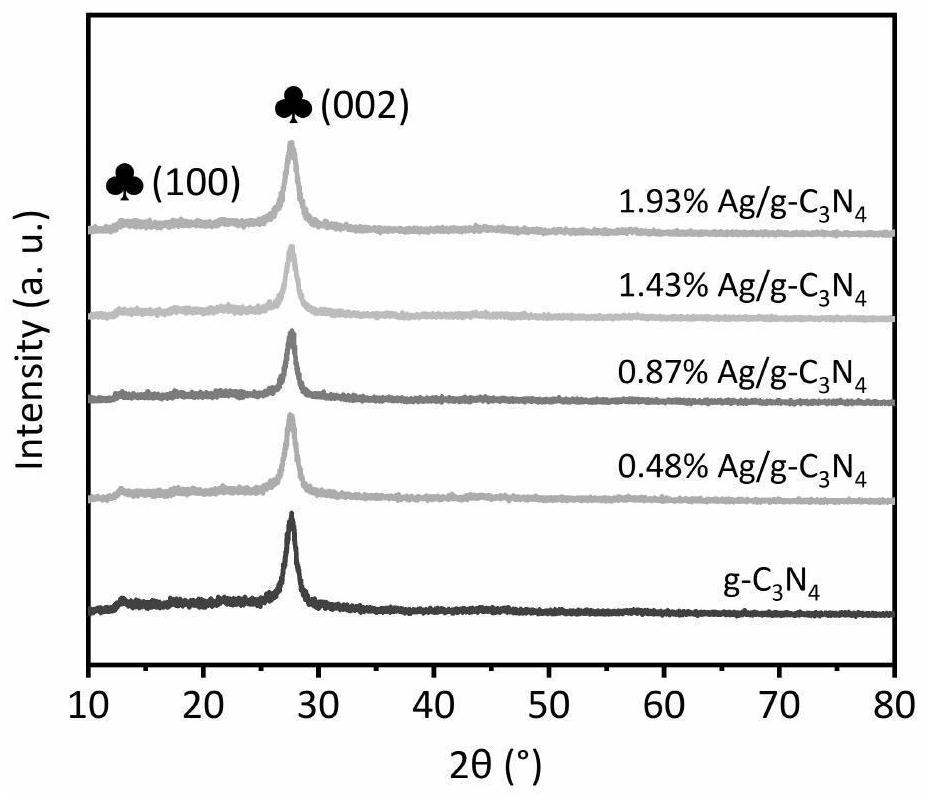

Embodiment 1

[0042] a. Put 15g of urea into an alumina crucible, heat up to 550°C with a heating rate of 2°C / min in a muffle furnace, and then cool to room temperature, then heat up to 550°C with a heating rate of 5°C / min Carry out calcination, and finally, after it is lowered to room temperature, the temperature is raised to 550° C. at a heating rate of 2° C. / min for calcination to obtain a pale yellow solid powder material, which is ground evenly and used for later use.

[0043] b. Take 0.1 g of the light yellow solid powder material obtained in step a and place it in 30 mL of deionized water, and stir fully to obtain a uniformly dispersed g-C 3 N 4 / water mixed solution;

[0044] c. Add 0.10 mL of AgNO with a concentration of 1 mg / mL dropwise 3 solution, so that the Ag loading is controlled at 0.48% (mass fraction);

[0045] d, adding AgNO in step c 3 g-C 3 N 4 / Water mixed solution is ultrasonically treated, and a uniform pale yellow suspension is obtained after ultrasonication f...

Embodiment 2

[0050] a. Put 15g of urea into an alumina crucible, heat up to 550°C with a heating rate of 2°C / min in a muffle furnace, and then cool to room temperature, then heat up to 550°C with a heating rate of 5°C / min Carry out calcination, and finally, after it is lowered to room temperature, the temperature is raised to 550° C. at a heating rate of 2° C. / min for calcination to obtain a pale yellow solid powder material, which is ground evenly and used for later use.

[0051] b. Take 0.1 g of the light yellow solid powder material obtained in step a and place it in 30 mL of deionized water, and stir fully to obtain a uniformly dispersed g-C 3 N 4 / water mixed solution;

[0052] c. Add 0.25mL of AgNO with a concentration of 1mg / mL dropwise 3 solution, so that the Ag loading is controlled at 0.87% (mass fraction);

[0053] d, adding AgNO in step c 3 g-C 3 N 4 / Water mixed solution is ultrasonically treated, and a uniform pale yellow suspension is obtained after ultrasonication for...

Embodiment 3

[0058] a. Put 15g of urea into an alumina crucible, heat up to 550°C with a heating rate of 2°C / min in a muffle furnace, and then cool to room temperature, then heat up to 550°C with a heating rate of 5°C / min Carry out calcination, and finally, after it is lowered to room temperature, the temperature is raised to 550° C. at a heating rate of 2° C. / min for calcination to obtain a pale yellow solid powder material, which is ground evenly and used for later use.

[0059] b. Take 0.1 g of the light yellow solid powder material obtained in step a and place it in 30 mL of deionized water, and stir fully to obtain a uniformly dispersed g-C 3 N 4 / water mixed solution;

[0060] c. Add 0.40 mL of AgNO with a concentration of 1 mg / mL dropwise 3 solution, so that the Ag loading is controlled at 1.43% (mass fraction);

[0061] d, adding AgNO in step c 3 g-C 3 N 4 / Water mixed solution is ultrasonically treated, and a uniform pale yellow suspension is obtained after ultrasonication f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com