Method for purifying copper foil

A purification method and copper foil technology, applied in chemical instruments and methods, single crystal growth, polycrystalline material growth, etc., can solve the problems of high difficulty in preparation and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

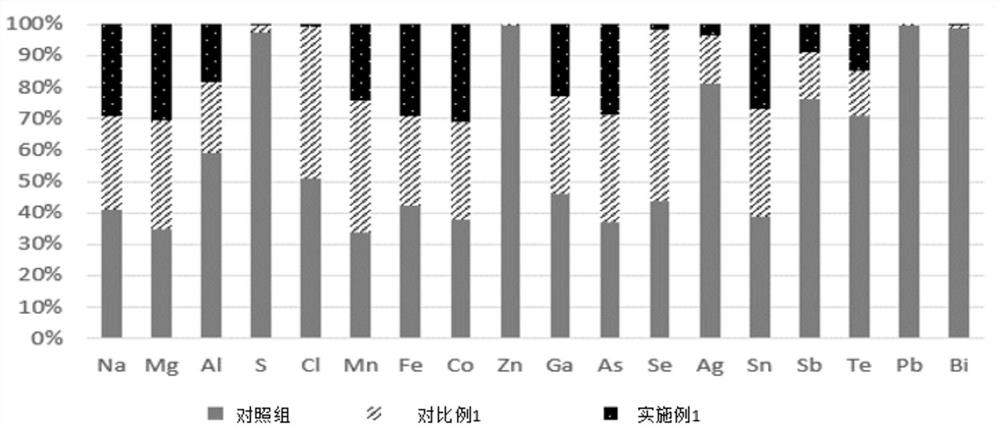

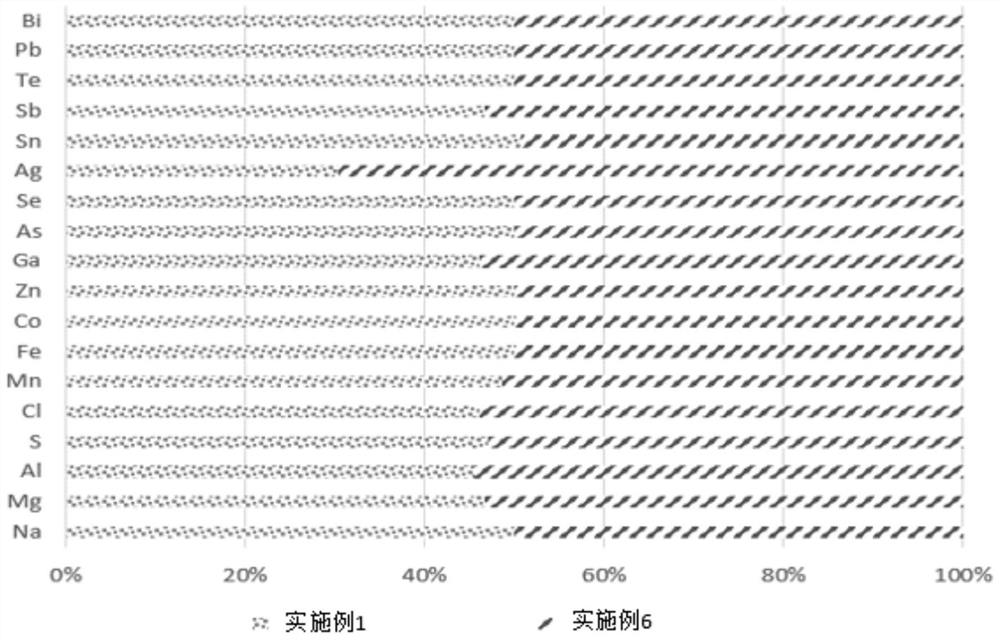

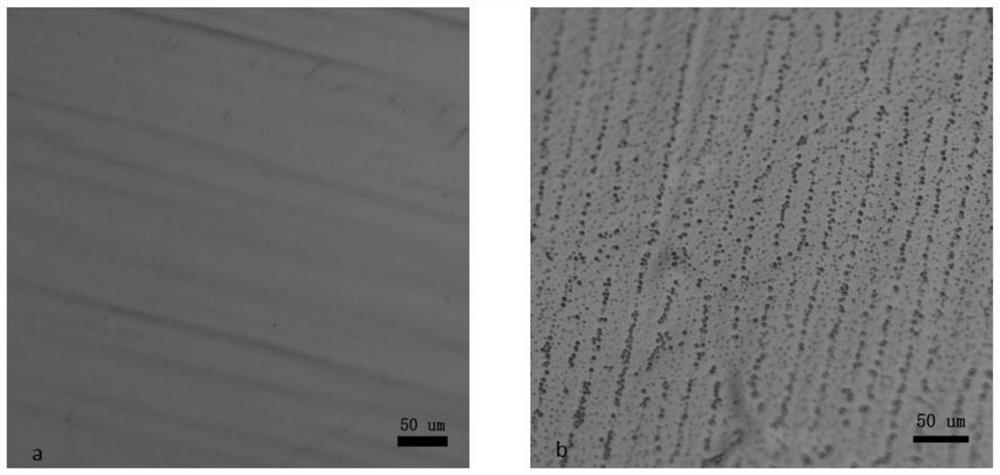

[0046] In the actual preparation process, the inventors found that although the above-mentioned specific annealing temperature and time can effectively improve the purification effect, the final purified single crystal copper foil still has certain impurities and the phenomenon of surface roughness, and further research is carried out for this purpose. It is found that the reason for the rough surface is the influence of the mixed atmosphere on the one hand, and the detachable pipe plugs at both ends of the tube furnace, which can ensure that the temperature in the furnace cavity is as balanced as possible, thereby reducing the temperature in the furnace cavity to a certain extent. The temperature difference between the copper foil in the middle and the copper foil at both ends of the furnace cavity is different, but due to the high annealing temperature, the impurities in the tube plug will be vaporized and deposited on the surface of the final single crystal copper foil during...

Embodiment 1

[0057] Place high-purity graphite paper (impurity content 200ppm) on high-purity quartz plate (6N), and place polycrystalline copper foil with a thickness of 25 μm on high-purity graphite paper to obtain polycrystalline copper foil / high-purity graphite paper / high Pure Quartz Plate.

[0058] Put the polycrystalline copper foil / high-purity graphite paper / high-purity quartz plate into the central temperature zone of the tube furnace. No pipe plugs are added at both ends of the tube furnace, and argon and hydrogen are introduced into the tube furnace. In an atmosphere with an argon flow rate of 600 sccm and a hydrogen flow rate of 38 sccm, keep the temperature of the central temperature zone of the tube furnace at 1065 ℃ for 5 h. Cool to room temperature naturally.

Embodiment 2

[0060] Place high-purity graphite paper (impurity content 200ppm) on high-purity quartz plate (6N), and place polycrystalline copper foil with a thickness of 25 μm on high-purity graphite paper to obtain polycrystalline copper foil / high-purity graphite paper / high Pure Quartz Plate.

[0061] Put the polycrystalline copper foil / high-purity graphite paper / high-purity quartz plate into the central temperature zone of the tube furnace. No pipe plugs are added at both ends of the tube furnace, and argon and hydrogen are introduced into the tube furnace. In an atmosphere where the flow rate of argon gas is 600sccm and the flow rate of hydrogen gas is 30sccm, the temperature of the central temperature zone of the tube furnace is kept at 1050 ℃ for 5h. Cool to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com