Polyurethane elastomer material as well as preparation method and application thereof

A polyurethane elastomer and modified technology, applied in the field of wear-resistant materials, can solve the problems of wear of soles, unsuitable wear, and poor slip resistance, so as to improve wear resistance, strengthen connection, and prolong storage period and service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

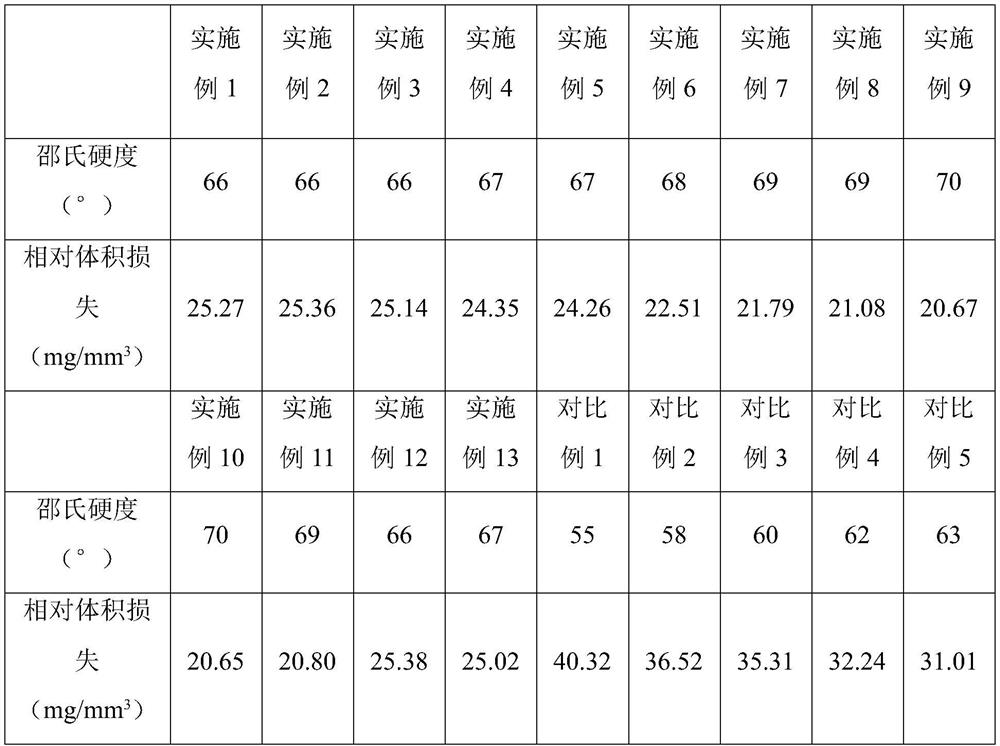

Examples

preparation example 1

[0047] A preparation method of modified montmorillonite, comprising the following steps:

[0048] Add 10kg of common montmorillonite to 90kg of water while stirring to obtain a suspension, heat the suspension to 80°C, add 50kg of acrylamide to the suspension while stirring under heating conditions, continue stirring for 30min, and filter to obtain modified montmorillonite earth.

preparation example 2

[0050] A preparation method of modified montmorillonite, comprising the following steps:

[0051]Add ordinary montmorillonite to 105kg of water while stirring to obtain a suspension, heat the suspension to 90°C, add 75kg of acrylamide to the suspension while stirring under heating conditions, continue stirring for 40min, and filter to obtain modified montmorillonite .

preparation example 3

[0053] A preparation method of modified montmorillonite, comprising the following steps:

[0054] Add 11kg of common montmorillonite to 100kg of water while stirring to obtain a suspension, heat the suspension to 85°C, add 55kg of acrylamide to the suspension while stirring under heating conditions, continue stirring for 35min, and filter to obtain modified montmorillonite earth.

[0055] Preparation example of surface-modified silicon nitride

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com