Preparation method of coal-based high-performance activated carbon material for CO2 adsorption

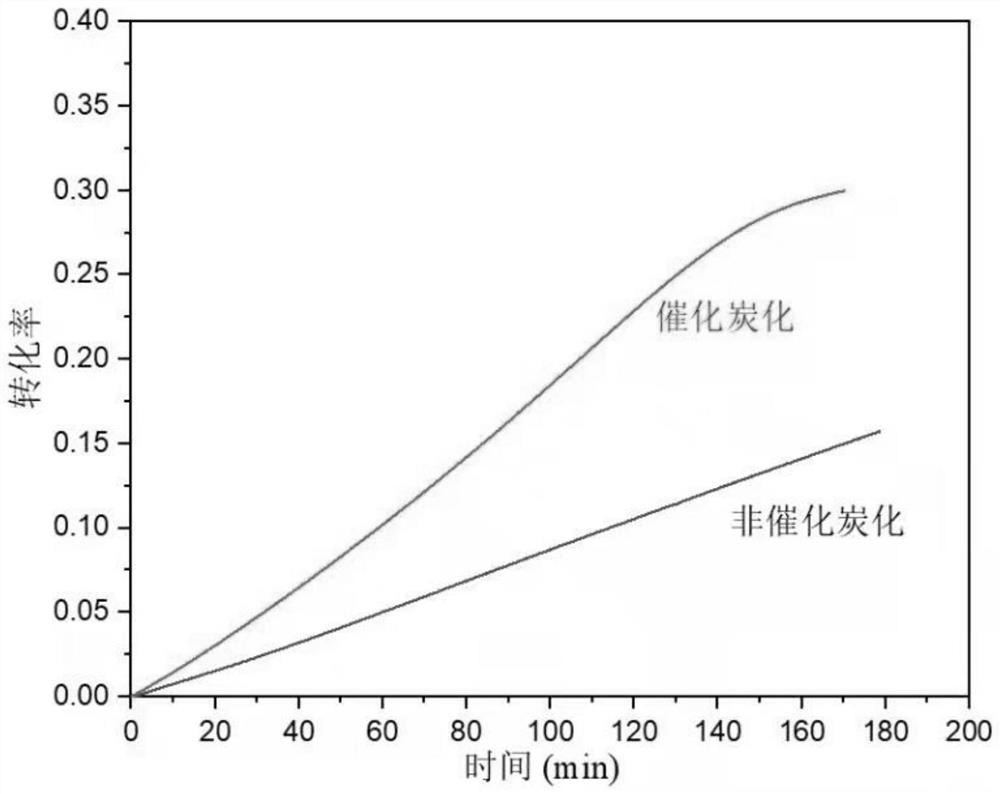

A high-performance, activated carbon technology, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., can solve the problems of poor cyclic adsorption performance, high carbonization reaction temperature, and low carbon yield, etc., and achieve good gas adsorption performance. The effect of reducing carbonization reaction temperature and high carbon yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In step A, the raw coal is ground and sieved to 200 meshes, and placed in an oven for drying for later use;

[0043] Step B, at room temperature, add 0.3 g FeSO 4 Mix it with 12g coal sample in a beaker, gradually add 200 drops of acetone, and stir with a glass rod until the solution becomes a paste, then add 250mL of deionized water while stirring with a glass rod, mix well and place it on a magnetic stirrer to continue Stir for 11 hours, place in an oven at 45°C for drying for 7 hours, and obtain a dry coal sample loaded with iron-based catalyst;

[0044] Step C, mix the dry sample of the supported iron-based catalyst obtained in step B with 0.1 g Na 2 CO 3 It was fully ground in an agate mortar for 30 minutes, and dried at 45°C for 7 hours after collection to obtain a dry coal sample loaded with sodium-iron composite catalyst;

[0045] In step D, the dry coal sample of the loaded sodium-iron composite catalyst obtained in step C is placed in a high-temperature tub...

Embodiment 2

[0048] In step A, the raw coal is ground and sieved to 200 meshes, and placed in an oven for drying for later use;

[0049] Step B, at room temperature, add 0.7 g FeSO 4 Mix it with 14g coal sample in a beaker, gradually add 300 drops of acetone, and stir with a glass rod until the solution becomes a paste, then add 350 mL of deionized water while stirring with a glass rod, mix well and place it on a magnetic stirrer to continue Stir for 13h, place in an oven at 55°C for drying for 9h, to obtain a dry coal sample loaded with iron-based catalyst;

[0050] Step C, using the mechanical method to support the sodium-based catalyst, mix the dry sample obtained in step B with 0.2 g Na 2 CO 3 It was fully ground in an agate mortar for 40 minutes, and then dried at 55°C for 9 hours after collection to obtain a dry coal sample loaded with sodium-iron composite catalyst;

[0051] In step D, the dry coal sample of the loaded sodium-iron composite catalyst obtained in step C is placed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com