Temperature and pressure integrated sensor and packaging method

A technology of temperature, pressure and sensors, which is applied in the field of sensor structures, can solve problems such as inconsistencies in the optimum working temperature of temperature-sensitive components, and achieve the effects of weakening heat transfer efficiency, reducing processing difficulty, and optimizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

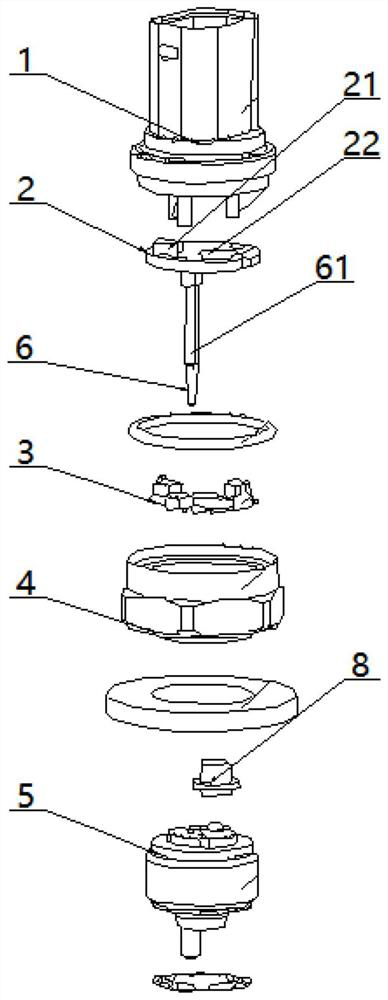

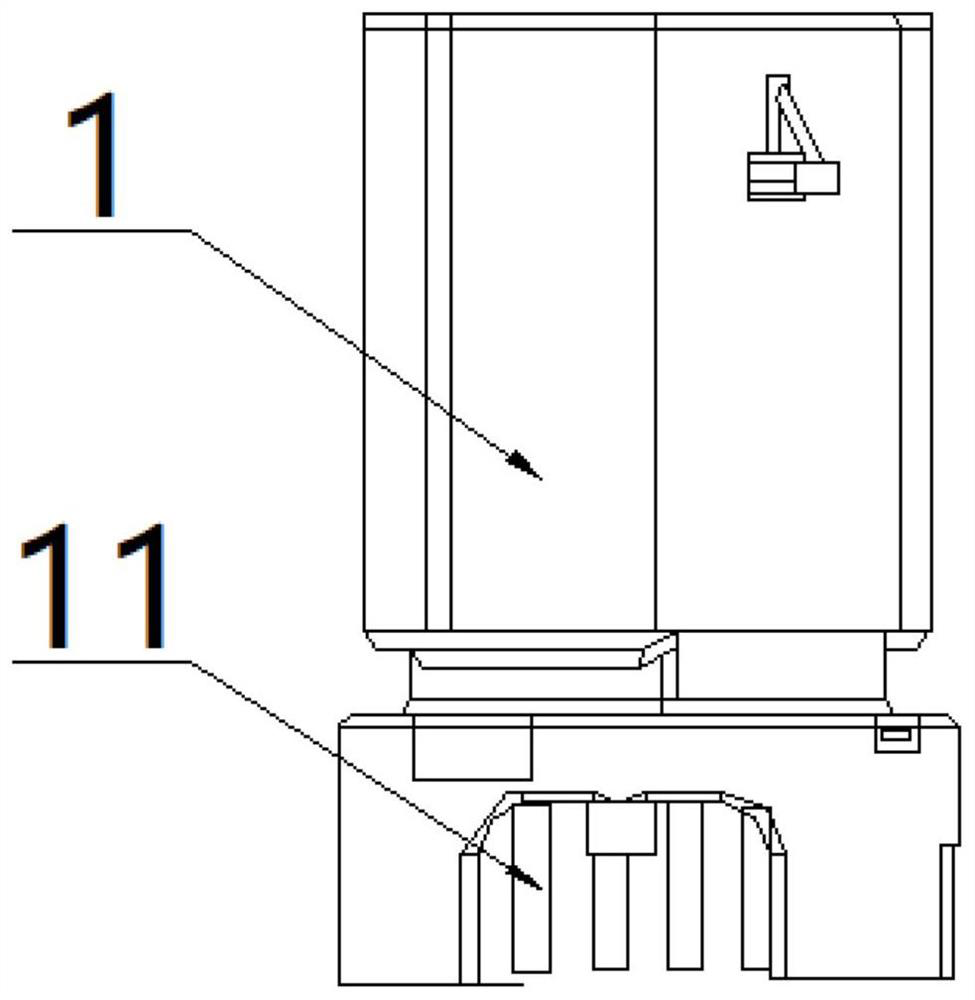

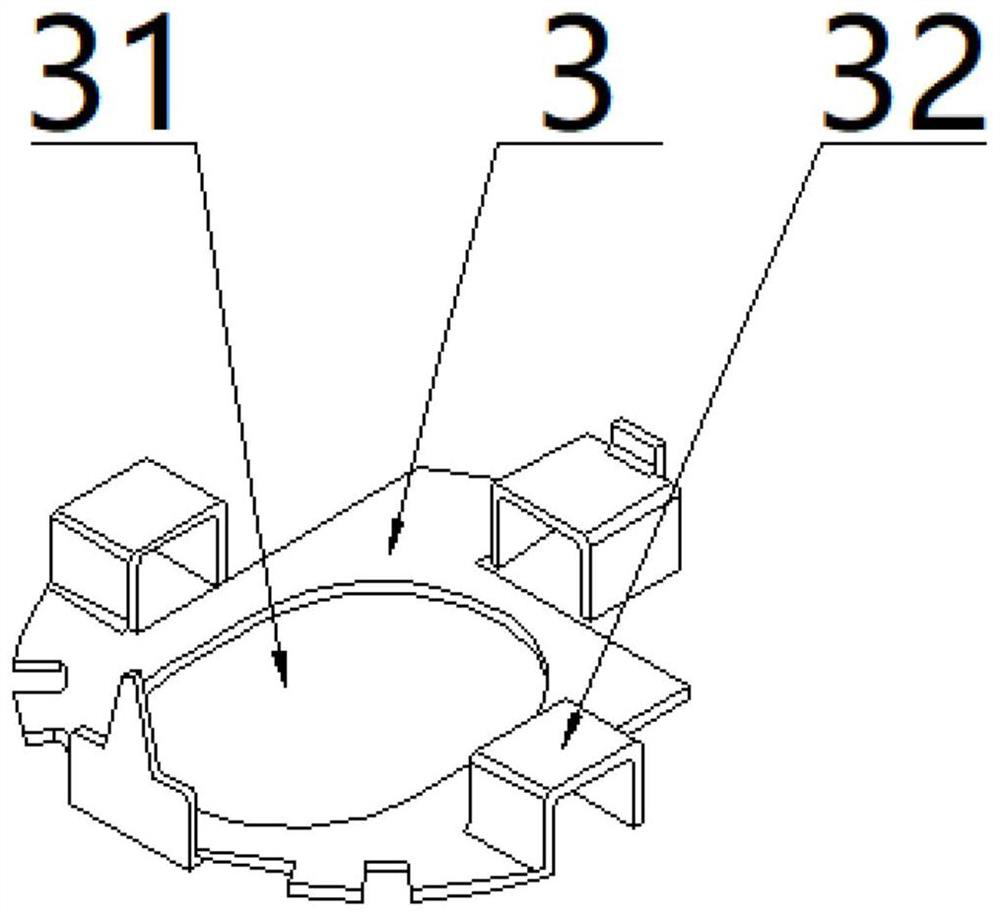

[0066] like figure 1 - Figure 8 As shown, an integrated temperature and pressure sensor includes a welded upper casing 4 and a lower casing 5, a support frame 3, a circuit board 2 and a plastic casing 1, the support frame 3 is arranged on the top of the upper casing 4, and the circuit board 2 is arranged on the support frame 3, the plastic casing 1 is arranged above the support frame 3 and is connected with the top of the upper casing 4, and the lower end of the lower casing 5 is sequentially formed with a threaded connector 51 and a first boss 52 from top to bottom. A boss 52 has a cylindrical structure and the diameter of the first boss 52 is smaller than the diameter of the threaded connector 51 ; the upper casing 4 and the lower casing 5 are both made of stainless steel.

[0067] like Figure 4 - Figure 7 As shown, the lower end of the first boss 52 is formed with a temperature measurement probe 7 downward, and the temperature measurement probe 7 is provided with a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com