Treatment method of high-silver-content low-grade alloyed gold

A treatment method and a technology of high-quality gold, which is applied in the field of clean production for efficiently separating gold and silver, can solve problems such as difficult gold and silver separation, and achieve the effects of improving gold recovery rate, reducing loss, and improving comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1, the main components of a company's alloy gold are Au55%, Ag16%, Zn18%, and Pb15%. Because the silver content is higher than 8%, the gold and silver wrapping phenomenon occurs in the traditional aqua regia gold process, and it is difficult to realize the separation of gold and silver by the traditional aqua regia gold method, so the processing method of the high silver content and low grade alloy gold of the present invention is adopted .

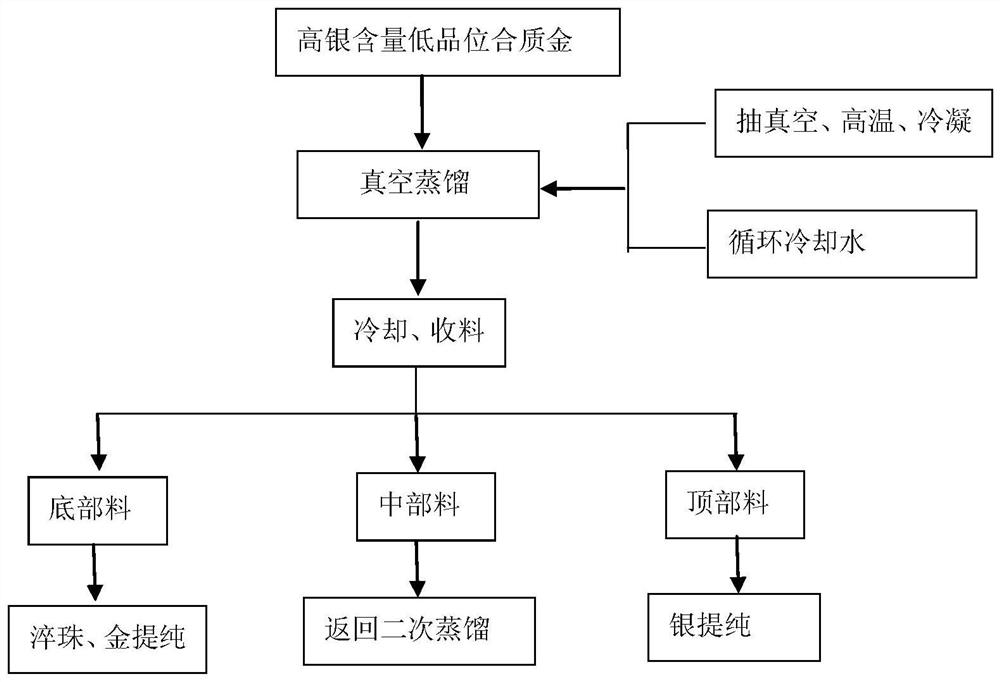

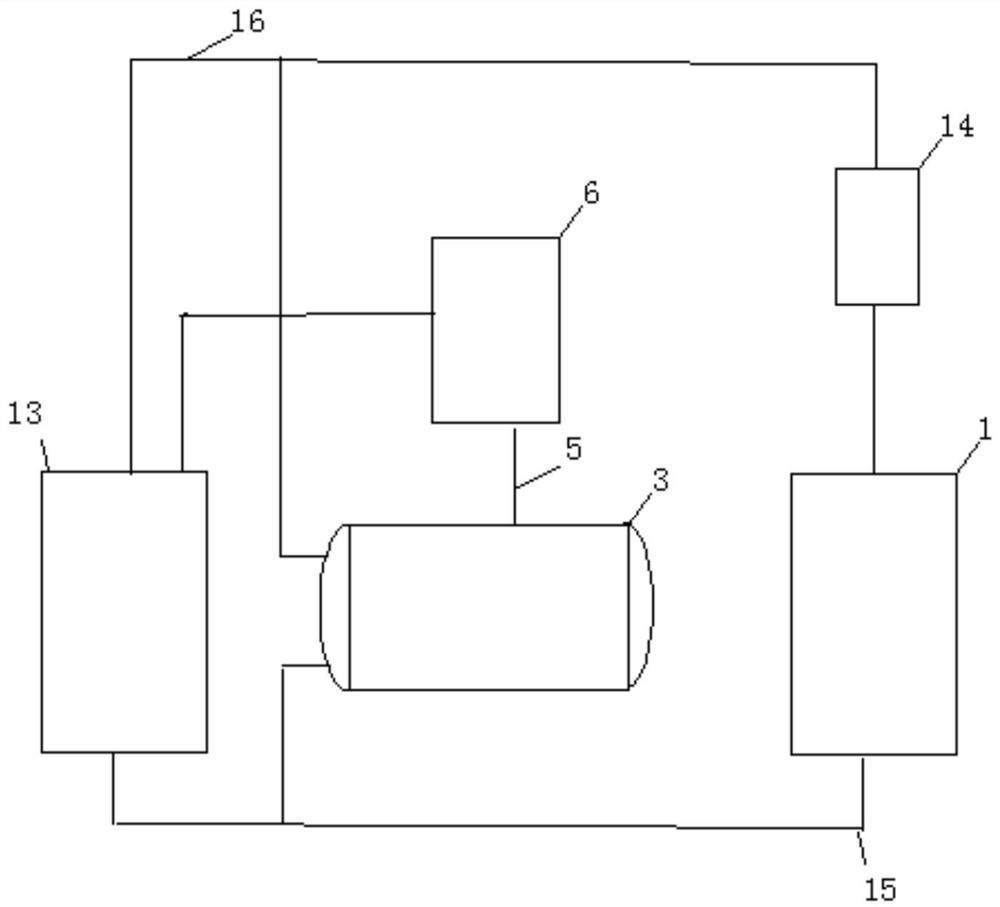

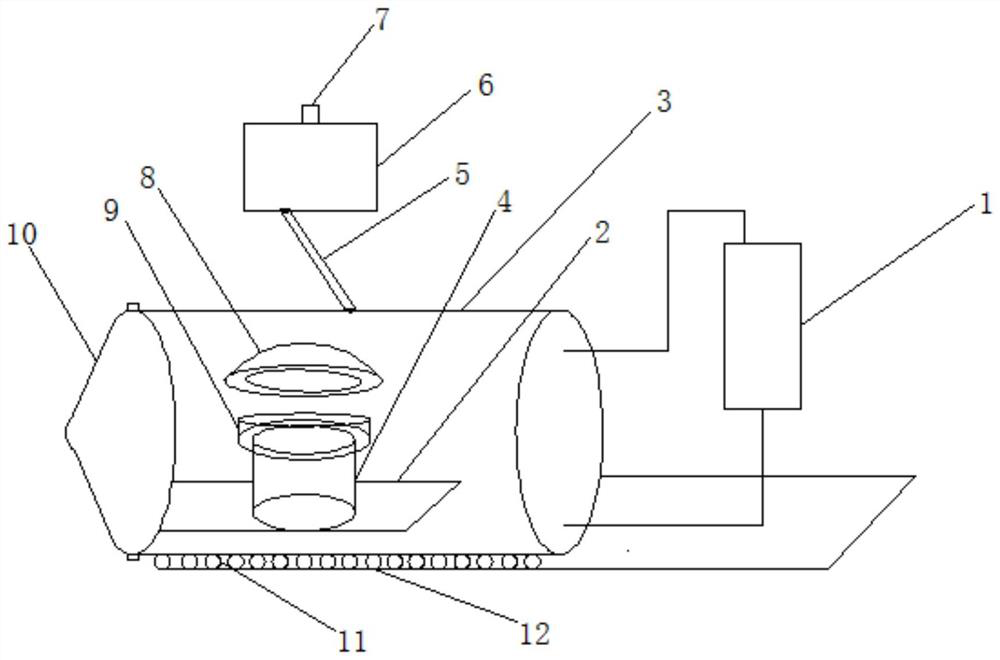

[0030] Figure 1-Figure 3 As shown, the gold smelting wastewater quality separation treatment method of the present invention comprises the following operation steps:

[0031] A. Material preparation: For high-silver content and low-grade alloy gold with a moisture content higher than 10%, it needs to be dried until the moisture content is less than or equal to 10%, and then enter step B;

[0032] B. High vacuum distillation: Since the boiling point of gold is significantly higher than that of silver, the difference betwe...

Embodiment 2

[0040] Example 2, the main components of imported alloy gold are Au63.5%, Ag19.3%, Zn21.2%, Pb13.2%. Because the silver content is higher than 8%, the gold and silver wrapping phenomenon occurs in the traditional aqua regia gold process, and it is difficult to realize the separation of gold and silver by the traditional aqua regia gold method, so the processing method of high silver content and low grade alloy gold of the present invention is adopted. .

[0041] The operation steps are the same as in Example 1, and the process condition parameters and the related parameters of the processed materials are shown in Table 3.

[0042] Table 3 embodiment 2 data statistics

[0043] The primary recovery rate of gold in the bottom material is 93.49%, the gold content is 71.16%, and the silver content is 6.8%. For the alloy gold containing less than 8% silver and more than 60% gold, the traditional aqua regia gold method can be used for smelting and purification; the intermediate ma...

Embodiment 3

[0044] Example 3, the main components of alloy gold in a domestic mine are Au 59.2%, Ag 15.3%, Zn 18.5%, and Pb 12.8%. Because the silver content is higher than 8%, the gold and silver wrapping phenomenon occurs in the traditional aqua regia gold process, and it is difficult to realize the separation of gold and silver by the traditional aqua regia gold method, so the processing method of high silver content and low grade alloy gold of the present invention is adopted. .

[0045] The operation steps are the same as in Example 1, and the process condition parameters and the related parameters of the processed materials are shown in Table 4.

[0046] Table 4 embodiment 3 data statistics

[0047]

[0048] The primary recovery rate of gold in the bottom material is 93.83%, the gold content is 72.6%, and the silver content is 6.91%. For the alloy gold containing less than 8% silver and more than 60% gold, the traditional aqua regia gold method can be used for smelting and purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com