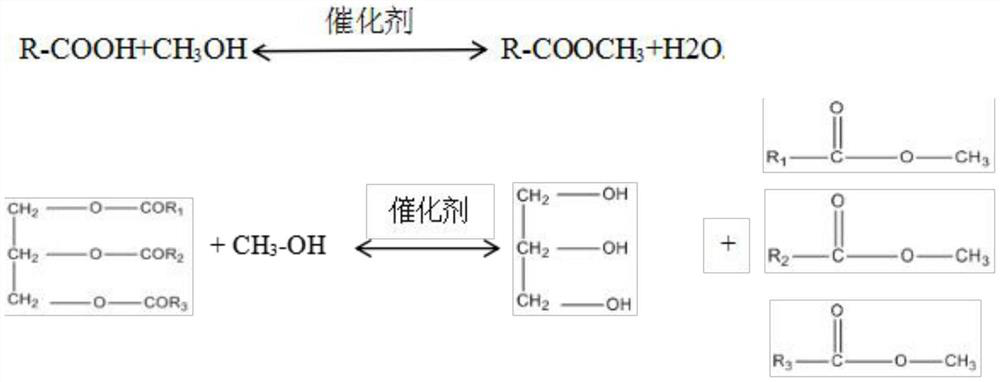

Preparation method and application of composite catalyst for preparing biodiesel

A composite catalyst and biodiesel technology, applied in the direction of fixing on/in organic carrier, fermentation, hydrolytic enzyme, etc., can solve the problems of high operating cost, large investment, side reaction of unsaturated fatty acid, etc., and achieve process green environmental protection , The effect of small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

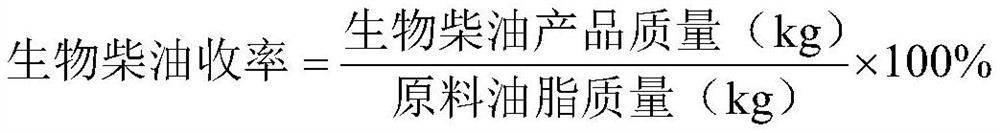

Examples

Embodiment 1

[0089] Example 1: Preparation of Biodiesel Composite Catalyst

[0090] The implementation steps of this embodiment are as follows:

[0091] Using pH7.2 phosphate buffer, the Candida lipase was prepared into a lipase solution with a concentration of 18 mg / ml, and then according to the glutaraldehyde concentration of 0.6% by weight, glutaraldehyde was added to the lipase solution, The obtained mixture solution was shaken in a constant temperature shaker at a temperature of 40°C for 1.0h;

[0092] Then, according to the weight ratio of lipase to resin of 1:8, a strong acid ion exchange resin was added to continue shaking for 5.6 hours, suction filtration, and the obtained resin was washed with a pH 7.2 phosphate buffer until no lipase was detected in the washing liquid, and the loaded fat was obtained. The strong acid ion exchange resin of the enzyme is detected by the method described in this specification, and its lipase loading is 85 mg / g;

[0093] Next, the strongly acidic ...

Embodiment 2

[0103] Example 2: Preparation of Biodiesel Composite Catalyst

[0104] The implementation steps of this embodiment are as follows:

[0105] Using pH7.2 phosphate buffer, Novozyme 435 lipase was prepared into a lipase solution with a concentration of 5 mg / ml, and then glutaraldehyde was added to the lipase solution according to the glutaraldehyde concentration of 1.0% by weight, The obtained mixture solution was shaken for 2.0h at a temperature of 20°C in a constant temperature shaker;

[0106] Then, according to the weight ratio of lipase to resin 1:5, a strong acid ion exchange resin was added to continue to shake for 4.0 hours, suction filtration, and the obtained resin was washed with a pH 7.2 phosphate buffer until no lipase was detected in the washing liquid, and the loaded fat was obtained. The strong acid ion exchange resin of the enzyme is detected by the method described in this specification, and its lipase loading is 100 mg / g;

[0107] Next, the strongly acidic io...

Embodiment 3

[0117] Example 3: Preparation of Biodiesel Composite Catalyst

[0118] The implementation steps of this embodiment are as follows:

[0119] Using pH7.2 phosphate buffer, TL-IM lipase was prepared into a lipase solution with a concentration of 8 mg / ml, and then glutaraldehyde was added to the lipase solution according to the glutaraldehyde concentration of 0.1% by weight, The obtained mixture solution was shaken at a temperature of 24°C for 1.6h in a constant temperature shaker;

[0120] Then, according to the weight ratio of lipase to resin 1:11, a strong acid ion exchange resin was added to continue shaking for 4.8 hours, suction filtration, and the obtained resin was washed with pH 7.2 phosphate buffer until no lipase was detected in the washing liquid, and the loaded fat was obtained. The strong acid ion exchange resin of the enzyme is detected by the method described in this specification, and its lipase loading is 41 mg / g;

[0121] Next, the strongly acidic ion exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com