Zero discharge technology of diatomite-sodalite composite material

A technology of composite materials and diatomite, which is applied in the zero-emission field of preparing diatomite-sodalite composite materials, can solve the problems of high raw material cost, complex process, high energy consumption, etc., and achieve reduced production costs and environmentally friendly processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

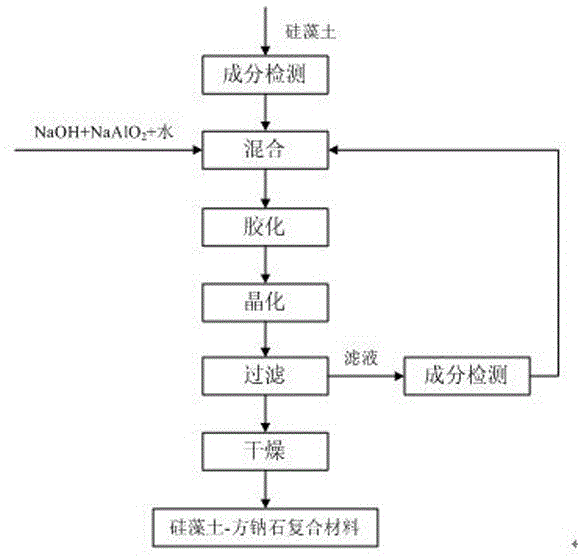

[0027] A zero-emission technology for preparing diatomite-sodalite composite material, the technology comprises the following steps:

[0028] (1) measure the composition content of diatomite, its composition content is shown in Table 1, diatomite, NaOH, NaAlO 2 and water, in molar ratio, as SiO 2 / Al 2 o 3 =2.0, Na 2 O / SiO 2 =1.2,H 2 O / Na 2 Add the ratio of O=40 into the reactor, at 80°C, the stirring rate is 200rpm, mix and react for 1h, and form a diatomaceous earth-gel mixture;

[0029] (2) crystallize the diatomaceous earth-gel mixture obtained in step (1) at 100° C. for 6 h;

[0030] (3) Filtrate to obtain a filter cake and a filtrate, and dry the filter cake at 50° C. to obtain a diatomite-sodalite composite material. The filtrate enters the step (1) according to its composition proportioning for recycling.

Embodiment 2

[0032] A zero-emission technology for preparing diatomite-sodalite composite material, the technology comprises the following steps:

[0033] (1) measure the composition content of diatomite, its composition content is shown in Table 1, diatomite, NaOH, NaAlO 2 and water, in molar ratio, as SiO 2 / Al 2 o 3 =2.2, Na 2 O / SiO 2 = 1.5, H 2 O / Na 2 O=45. Add it into the reactor, at 70°C, with a stirring rate of 200rpm, mix and react for 3h to form a diatomaceous earth-gel mixture;

[0034] (2) Crystallize the diatomaceous earth-gel mixture obtained in step (1) at 90° C. for 6 h;

[0035] (3) Filtrate to obtain a filter cake and a filtrate, and dry the filter cake at 50° C. to obtain a diatomite-sodalite composite material. The filtrate enters the step (1) according to its composition proportioning for recycling.

Embodiment 3

[0037] A zero-emission technology for preparing diatomite-sodalite composite material, the technology comprises the following steps:

[0038] (1) measure the composition content of diatomite, its composition content is shown in Table 1, diatomite, NaOH, NaAlO 2 and water, in molar ratio, as SiO 2 / Al 2 o 3 =2.3, Na 2 O / SiO 2 = 2.0, H 2 O / Na 2 O=35. Add it into the reactor, at 85°C, the stirring rate is 200rpm, and mix and react for 1h to form a diatomaceous earth-gel mixture;

[0039] (2) Crystallize the diatomaceous earth-gel mixture obtained in step (1) at 95° C. for 4 hours;

[0040] (3) Filtrate to obtain a filter cake and a filtrate, and dry the filter cake at 50° C. to obtain a diatomite-sodalite composite material. The filtrate enters the step (1) according to its composition proportioning for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com