Environment-friendly multi-component alloy auto-catalytic plating process

A multi-alloy, autocatalytic plating technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of affecting the performance of alloy plating, long period of replacement of plating solution, high maintenance cost, and achieve improvement Corrosion resistance, dispersing corrosion current, and strong co-deposition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

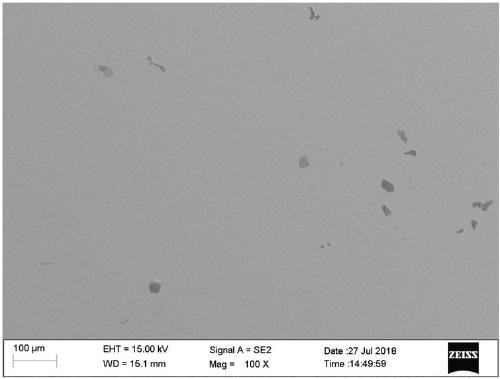

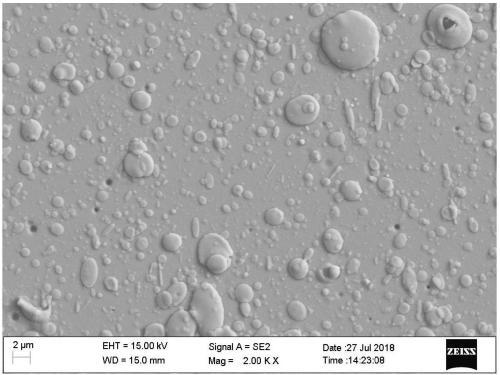

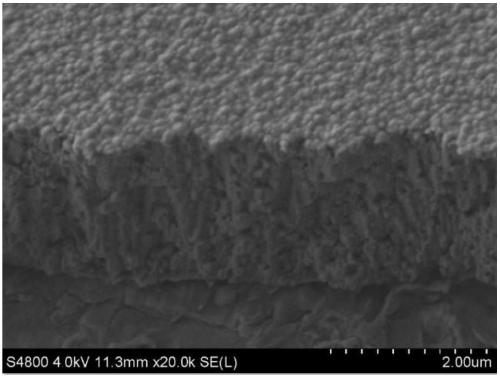

Image

Examples

Embodiment 1

[0042] The invention discloses an environment-friendly multi-element alloy autocatalytic plating process, comprising the following steps:

[0043] 1) Preparation of electroplating solution: Add choline chloride and ethylene glycol sequentially into a beaker according to the parts by mass, then heat to 60°C and stir for 20 minutes. After the solution becomes transparent, add tungsten chloride and chlorine Nickel, continue to stir evenly and then add boron tetrafluoride guanidinium salt ionic liquid, reducing agent, dispersant, lactic acid, sodium acetate, complexing agent, stir again and then set aside;

[0044] 2) Multi-element alloy coating self-catalysis treatment: place the cleaned metal workpiece in the solution obtained in step 1) and raise the temperature to 80°C for multi-element alloy plating, and the self-catalysis time is 30 minutes.

[0045] In this embodiment, the reducing agent is hydrazine sulfate; the dispersant is polyoxyethylene alkylphenol ether; the complexing...

Embodiment 2

[0048] The invention discloses an environment-friendly multi-element alloy autocatalytic plating process, comprising the following steps:

[0049] 1) Preparation of electroplating solution: Add choline chloride and ethylene glycol sequentially into a beaker according to the parts by mass, then heat to 50°C and stir for 40 minutes. After the solution becomes transparent, add tungsten chloride and chlorine Nickel, continue to stir evenly and then add boron tetrafluoride guanidinium salt ionic liquid, reducing agent, dispersant, lactic acid, sodium acetate, complexing agent, stir again and then set aside;

[0050] 2) Multi-element alloy coating self-catalysis treatment: place the cleaned metal workpiece in the solution obtained in step 1) and raise the temperature to 60°C for multi-element alloy plating, and the self-catalysis time is 10 minutes.

[0051] In this embodiment, the reducing agent is hydrazine sulfate; the dispersant is polyoxyethylene alkylphenol ether; the complexi...

Embodiment 3

[0054] The invention discloses an environment-friendly multi-element alloy autocatalytic plating process, comprising the following steps:

[0055] 1) Preparation of electroplating solution: Add choline chloride and ethylene glycol sequentially into a beaker according to the parts by mass, then heat to 60°C and stir for 30 minutes. After the solution becomes transparent, add tungsten chloride and chlorine Nickel, continue to stir evenly and then add boron tetrafluoride guanidinium salt ionic liquid, reducing agent, dispersant, lactic acid, sodium acetate, complexing agent, stir again and then set aside;

[0056] 2) Multi-element alloy coating self-catalysis treatment: place the cleaned metal workpiece in the solution obtained in step 1) and raise the temperature to 60°C for multi-element alloy plating, and the self-catalysis time is 10 minutes.

[0057] In this embodiment, the reducing agent is hydrazine sulfate; the dispersant is polyoxyethylene alkylphenol ether; the complexi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com