Alcohol compound, chemically amplified negative resist composition, and resist pattern forming method

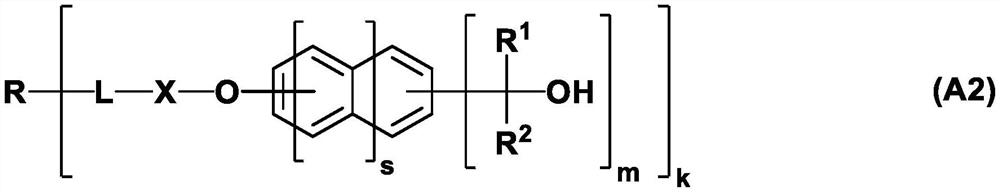

An alcohol compound, chemical amplification technology, applied in the direction of organic chemistry, optics, photolithography process of pattern surface, etc., can solve the problem of line edge roughness, line width, roughness, size uniformity deterioration, insufficient insolubilization of base polymer, polymer Insufficient insolubilization and other problems, to achieve the effect of excellent limit resolution, excellent insolubilization, and reduced solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0147] As shown in Scheme A, the first step in the synthesis of compound A1-1 is to react the intermediate In-A, which can be obtained in the form of a commercial product or can be synthesized by a known organic synthesis method, with a Grignard reagent or an organolithium reagent to obtain Procedure for intermediate In-B. The reaction can be carried out by a known organic synthesis method. Specifically, the Grignard reagent or the organolithium reagent is diluted in a solvent such as tetrahydrofuran (THF) and diethyl ether, and a solution obtained by dissolving the intermediate In-A in a solvent such as THF and diethyl ether is added dropwise thereto. reaction. The amount of Grignard reagent or organolithium reagent used should be (2m 1 +2) Equivalent. The reaction temperature is preferably in the range from room temperature to about the boiling point of the solvent used. When the reaction time is followed by gas chromatography (GC) or silica gel thin layer chromatography...

Embodiment 1-1

[0335] [Example 1-1] Synthesis of crosslinking agent CA-1

[0336] (1) Synthesis of intermediate In-1

[0337] [Chemical 61]

[0338]

[0339]Under a nitrogen atmosphere, the Grignard reagent prepared from magnesium (145.9 g, 6 equivalents relative to M-1), THF (3,000 g) and methyl chloride was measured in the flask at the temperature in the flask (hereinafter referred to as the internal temperature). The solution which consists of M-1 (210g) and THF (500g) was dripped in the range of 40-55 degreeC. After the dropwise addition, it was aged for 3 hours at an internal temperature of 50°C. After aging, the reaction system was cooled, and a mixed aqueous solution of ammonium chloride (600 g) and a 3.0 mass % aqueous hydrochloric acid solution (1,800 g) was added dropwise to stop the reaction. Then, extraction was carried out with ethyl acetate (2,000 mL), the usual aqueous work-up was carried out, the solvent was distilled off, and In-1 was obtained as white crystals by recr...

Embodiment 1-2~1-15

[0346] [Examples 1-2 to 1-15] Synthesis of cross-linking agents CA-2 to CA-15

[0347] In addition, the crosslinking agents CA-2 to CA-15 were synthesized by the same organic synthesis method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com