Coking wastewater zero-discharge salt separation treatment system and method

A technology for coking wastewater and treatment systems, applied in natural water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of heat dissipation, high investment costs, large energy consumption, etc., and achieve strong impact load resistance , strong anti-fouling ability, accelerated separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

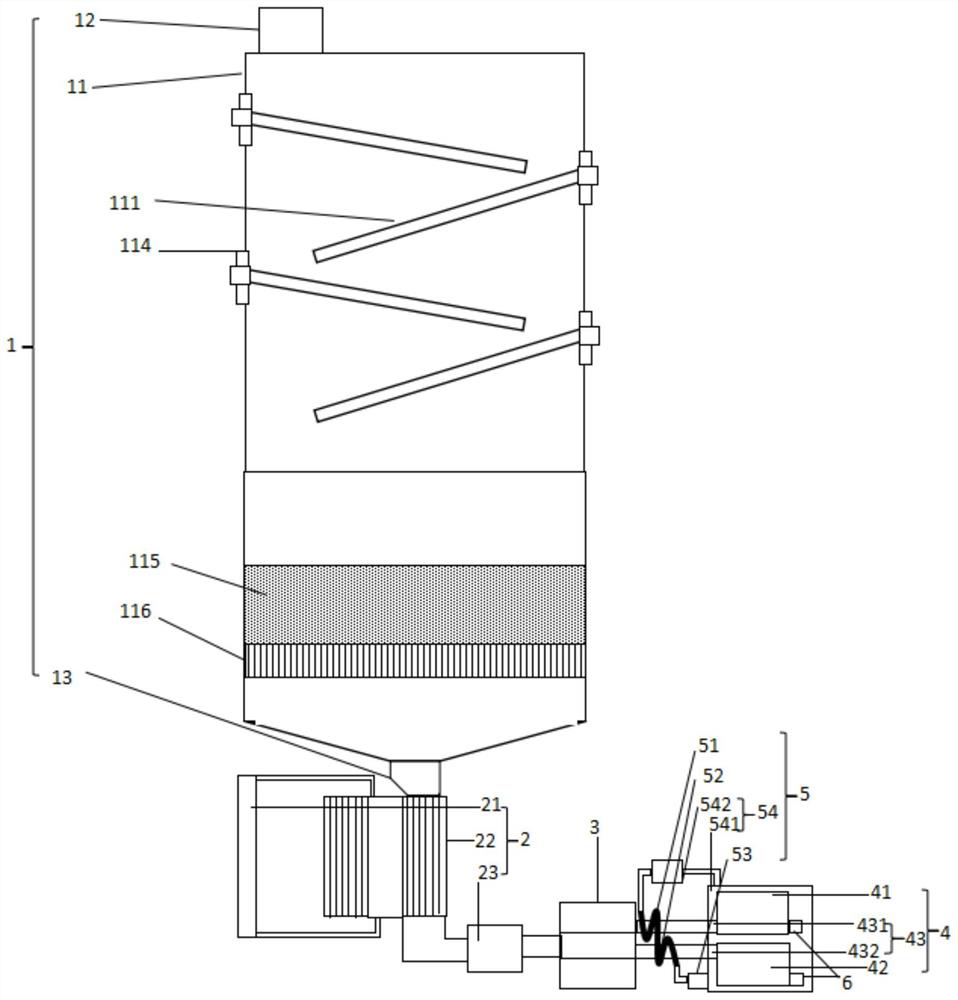

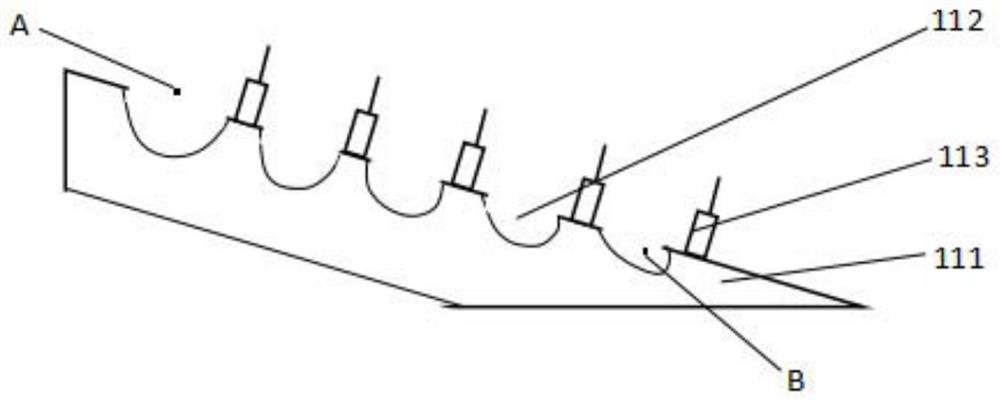

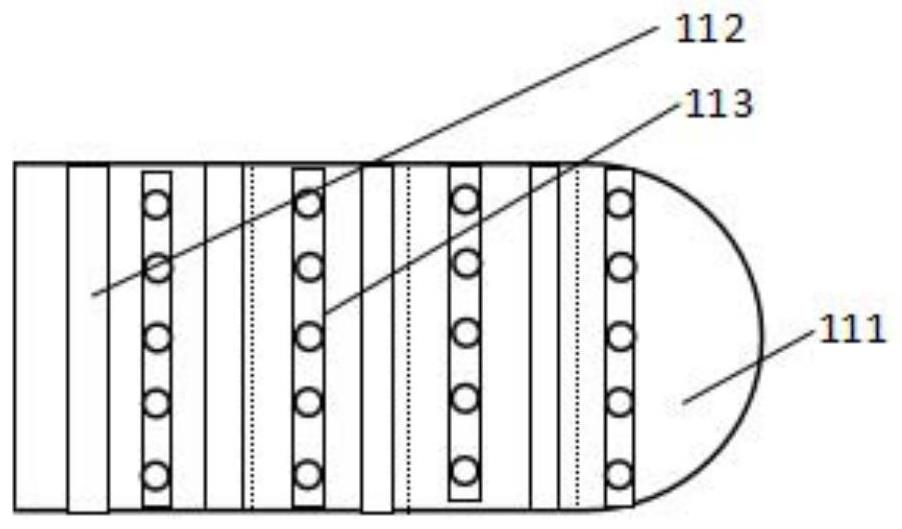

[0029] The present application provides a zero-discharge salt-separation treatment system for coking wastewater, which at least includes a pretreatment unit 1 , a concentration unit 2 , a separation unit 3 , a crystallization unit 4 and a preheating unit 5 .

[0030] According to a specific embodiment, the pretreatment unit 1 receives the coking wastewater and performs dehardening and filtration treatment on the coking wastewater. After the pretreatment is completed, the coking wastewater is directly transported to the concentration unit 2 for concentration treatment. The concentration unit 2 completes the concentration of the coking wastewater by drawing water, and sends the concentrated coking wastewater to the separation unit 3 for component separation treatment. The separation unit 3 constructs a nanofiltration separation unit 32 by setting a streamlined flow channel frame and forming a flow channel wall by wrapping the nanofiltration membrane around the flow channel frame....

Embodiment 2

[0057] The application also provides a zero-discharge salt-separation treatment method for coking wastewater, which at least comprises the following steps:

[0058] (1) Pretreatment: mainly remove hardness, silica, F-, CODcr and residual impurities in coking wastewater, eliminate the impact of impurities on membrane concentration and evaporative crystallization treatment, ensure the quality of crystalline salt, and reduce waste crystalline salt as much as possible quantity. To remove the hardness, most of the hardness is removed by the softening method of lime soda ash, and the remaining hardness is completely removed by the ion exchange method.

[0059] (2) Membrane concentration: mainly use two-stage membrane concentration to reduce water and increase the salt content of concentrated water; on this basis, use two-stage nanofiltration membrane to separate sodium sulfate and sodium chloride.

[0060] The weak acid cation bed effluent first enters the GTR3 medium-pressure memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com