Grinding machine for punching die

A grinding machine and grinding mechanism technology, applied in grinding machines, manufacturing tools, grinding drive devices, etc., can solve problems such as low efficiency, dust emission, dust accumulation in molds, etc., and achieve the effect of increasing punching quality and uniform grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

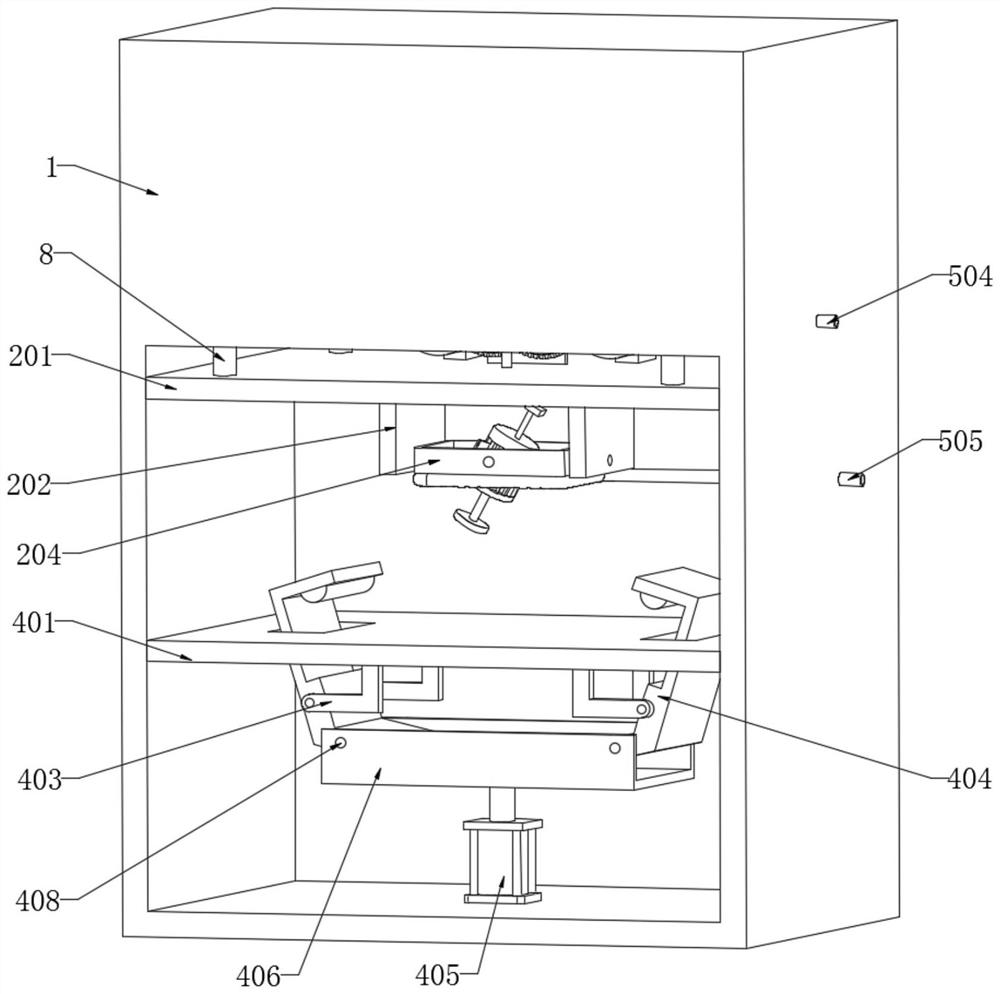

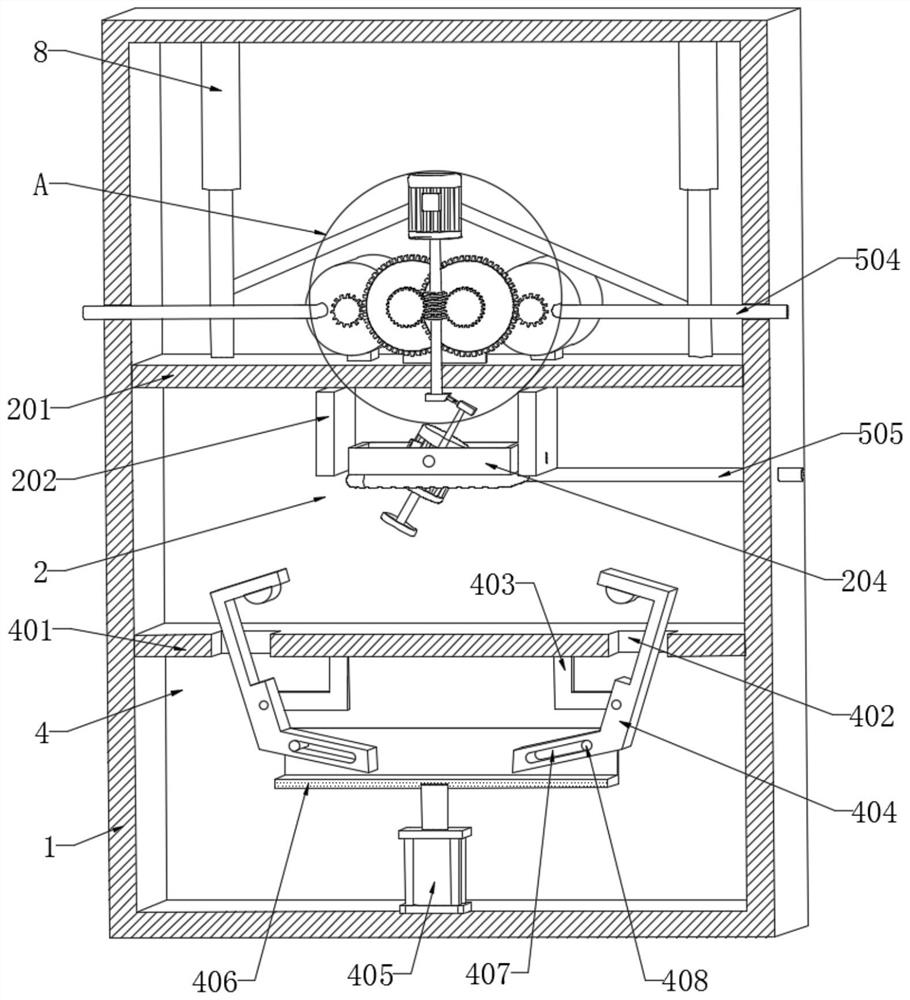

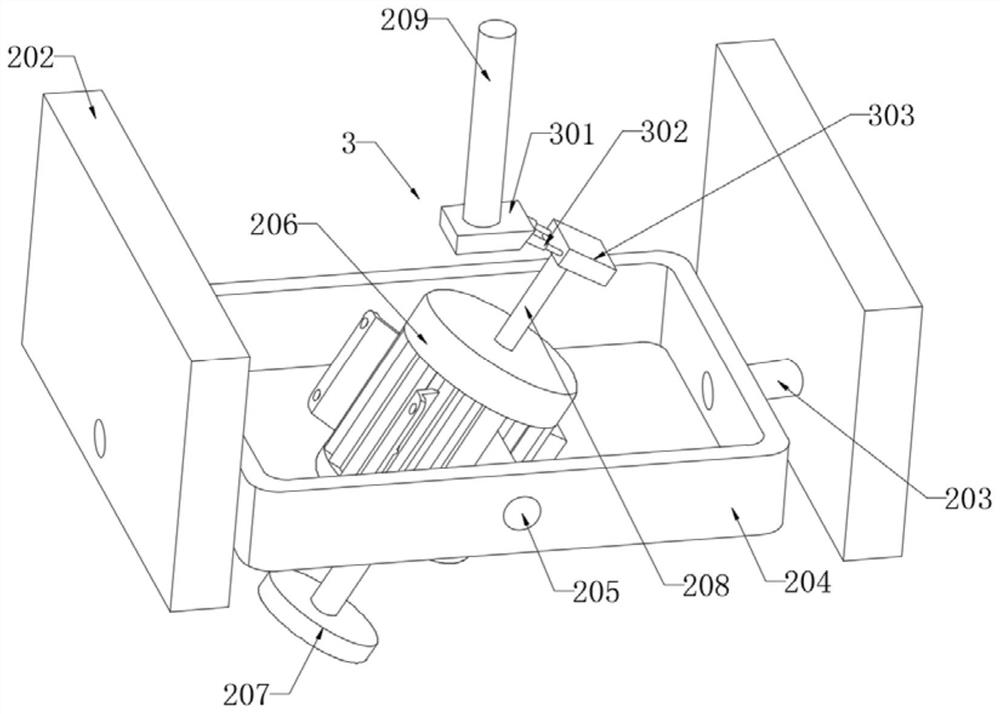

[0027] refer to figure 1 and 3 , a grinding machine for punching dies, comprising a casing 1, a grinding mechanism 2 for tilting the punching dies is provided in the casing 1, the grinding mechanism 2 comprises a horizontal plate 201 slidably connected to the inner wall of the casing 1, and the horizontal plate 201 The lower end is fixedly connected with two vertical plates 202 , and the side walls of the two vertical plates 202 are both connected to a ring frame 204 through the joint rotation of the first rotating shaft 203 . A servo motor 206 is connected, a grinding disc 207 is fixedly connected to the movable end of the servo motor 206, a fixing column 208 is fixedly connected to the side wall of the servo motor 206 away from the movable end, and a vertical rod 209 is rotatably connected to the side wall of the horizontal plate 201, and the lower end of the vertical rod 209 passes through The adjusting mechanism 3 is rotatably connected to one end of the fixing column 208...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com