Low-noise MEMS capacitive sensor interface circuit

A capacitive sensor and interface circuit technology, applied in the direction of logic circuit interface device, logic circuit connection/interface layout, amplifier using switched capacitors, etc., can solve the problem of signal-to-noise ratio reduction, gain accuracy deterioration, and overall power consumption increase of the interface circuit etc. to achieve the effect of reducing gain error, improving gain accuracy, and increasing circuit power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

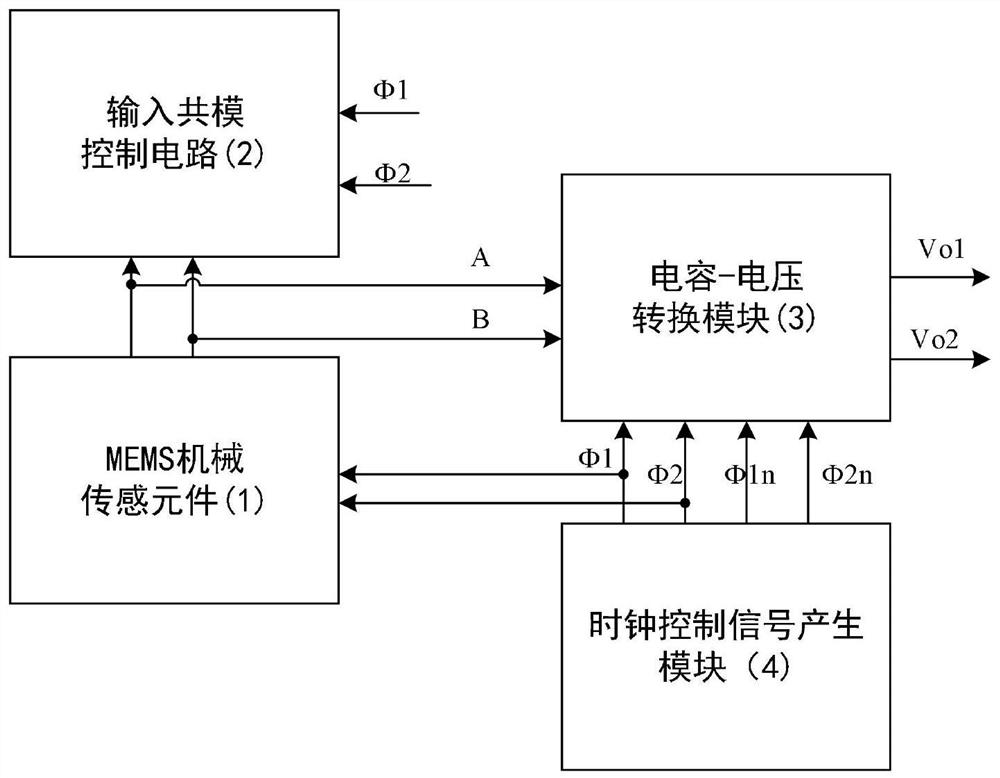

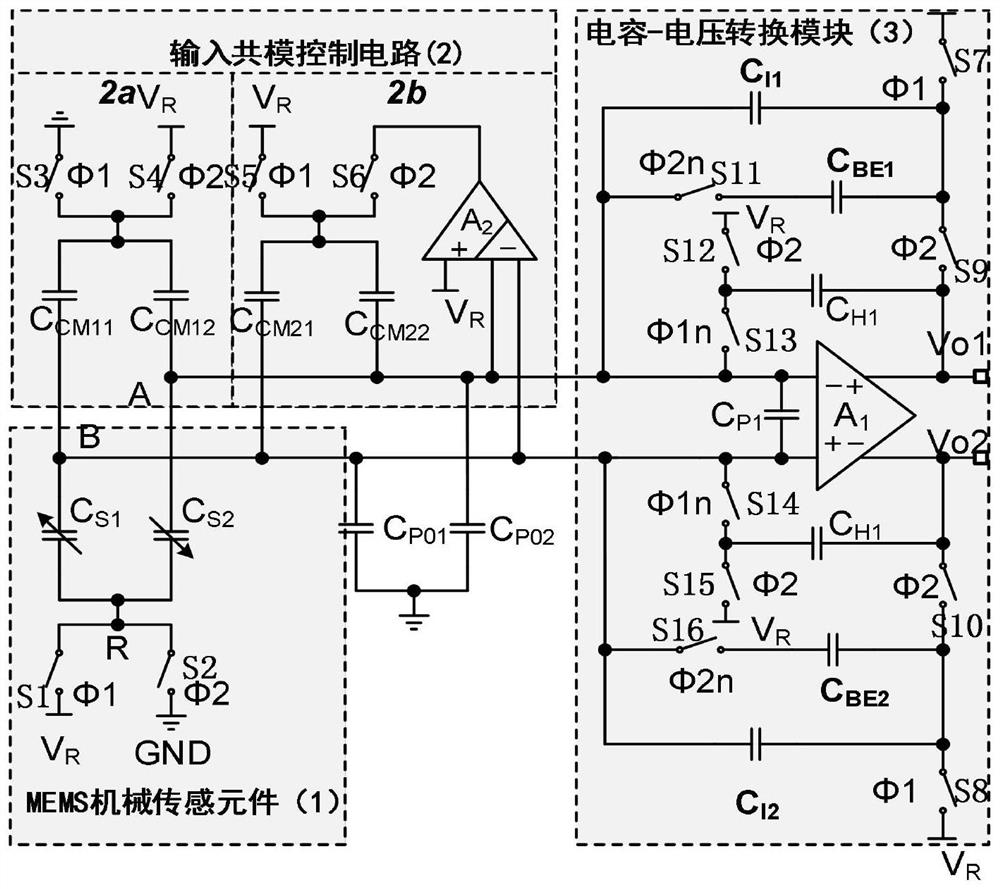

[0031] refer to figure 1 , the present invention includes a MEMS mechanical sensing element 1, an input common mode control circuit 2, a capacitance-voltage conversion module 3 and a clock control signal generation module 4;

[0032] The MEMS mechanical sensing element 1 is used to convert the external acceleration signal into the variation of the MEMS mechanical capacitance. The MEMS mechanical sensing element 1 is driven by the clock control signals Φ1 and Φ2 generated by the clock control signal generating module 4 to generate sensor charges. Signals A and B, the sensor charge signals A and B both include common mode charge components and differential mode charge components, wherein the common mode charge components are absorbed by the input common mode control circuit 2, and the differential mode components are transmitted to the capacitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com