Soybean lecithin modified emulsifier as well as preparation method and application thereof

A technology of soybean lecithin and soybean lecithin, which is applied in the field of petroleum drilling fluid, and achieves the effect of excellent electrical stability and high emulsification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

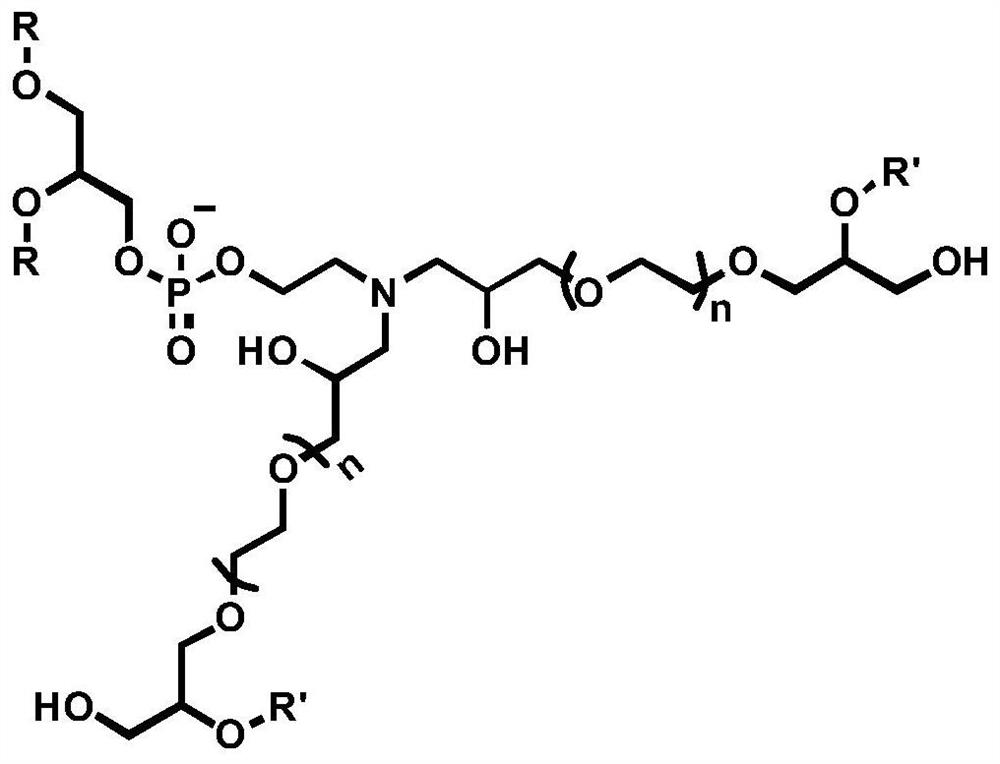

Image

Examples

Embodiment 1

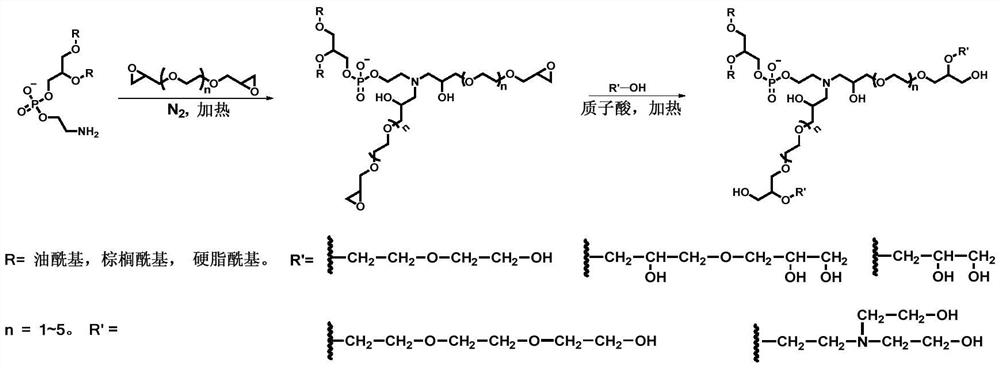

[0027] 24 g of soybean lecithin and 2 g of ethylene glycol glycidyl ether were added to a double-necked round bottom flask with a reflux condenser, and 40 mL of ethanol was added. Under nitrogen protection, the temperature was slowly raised to 60 °C in an oil bath magnetic stirrer, and after stirring for 3 h, the solvent ethanol was distilled off under reduced pressure.

[0028] 6 g of diethylene glycol was added to the reaction system, 0.2 g of concentrated sulfuric acid was added dropwise, and under nitrogen protection, the reaction was stirred at 70° C. for 2 hours to obtain a soybean lecithin modified emulsifier.

Embodiment 2

[0030] 21 g of soybean lecithin and 3 g of diethylene glycol glycidyl ether were added to a double-necked round-bottomed flask with a reflux condenser, and 50 mL of ethanol was added. Under nitrogen protection, the temperature was slowly raised to 70 °C in an oil bath magnetic stirrer, and after stirring for 5 h, the solvent ethanol was distilled off under reduced pressure.

[0031] 6 g of diethylene glycol was added to the reaction system, and 0.5 g of phosphoric acid was added dropwise, and under nitrogen protection, the reaction was stirred at 90° C. for 3 hours to obtain a soybean lecithin modified emulsifier.

Embodiment 3

[0033] 25 g of soybean lecithin and 5 g of polyethylene glycol glycidyl ether were added to a double-necked round-bottomed flask with a reflux condenser, and 25 mL of isopropanol was added. Under nitrogen protection, the temperature was slowly raised to 80 °C in an oil bath magnetic stirrer, and after stirring for 6 h, the solvent isopropanol was distilled off under reduced pressure.

[0034] 6 g of diethylene glycol was added to the reaction system, 0.5 g of p-toluenesulfonic acid was added, and under nitrogen protection, the reaction was stirred at 100° C. for 1 h to obtain a soybean lecithin modified emulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com