Light emitting diode with heat dissipation structure

A technology of light emitting diodes and heat dissipation structures, which is applied to semiconductor devices of light emitting elements, light sources, light source fixing and other directions, can solve the problems of inconvenient installation and disassembly of lighting equipment, low heat dissipation efficiency of light emitting diodes, etc. The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

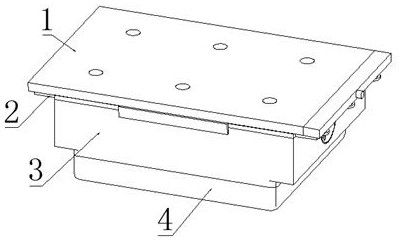

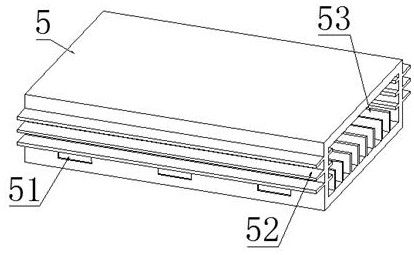

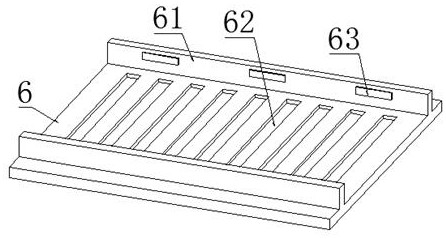

[0029] Example 1, refer to figure 1 , figure 2 and image 3 As shown, a light emitting diode with a heat dissipation structure includes a housing 3, a lamp board 6 is installed on the inner side of the housing 3, and the lower surface of the light board 6 is provided with evenly arranged light emitting diodes, and the lower end of the housing 3 is opened. The lower end of the casing 3 is clamped with the lampshade 4, the lamp plate 6 is clamped at the opening of the lower end of the casing 3, and the upper end of the lamp plate 6 is fixedly clamped with a heat dissipation seat 5 for heat dissipation, and the heat dissipation seat 5 and the lamp plate 6 pass through. The thermal conductive silicone grease has good thermal conductivity. The upper port of the casing 3 is provided with a cover plate 2, and the casing 3 is provided with a heat dissipation structure for dissipating the heat of the heat dissipation seat 5. The cover plate The upper side of 2 is clamped on the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com