Graphite-phase carbon nitride photocatalyst for sewage treatment and preparation method thereof

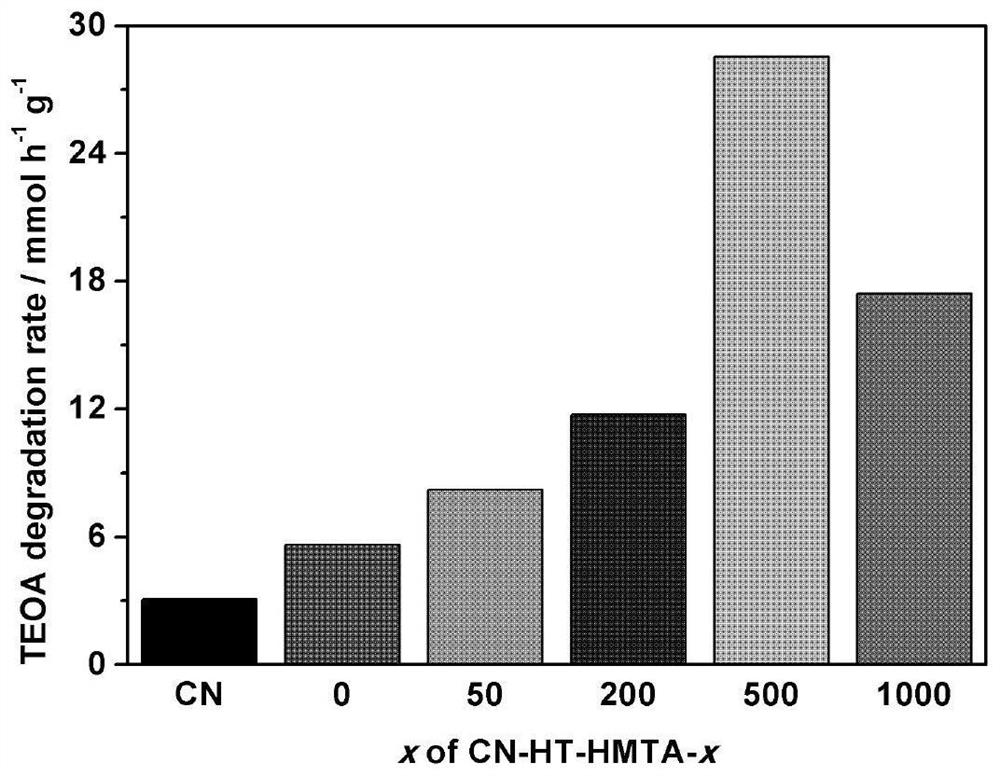

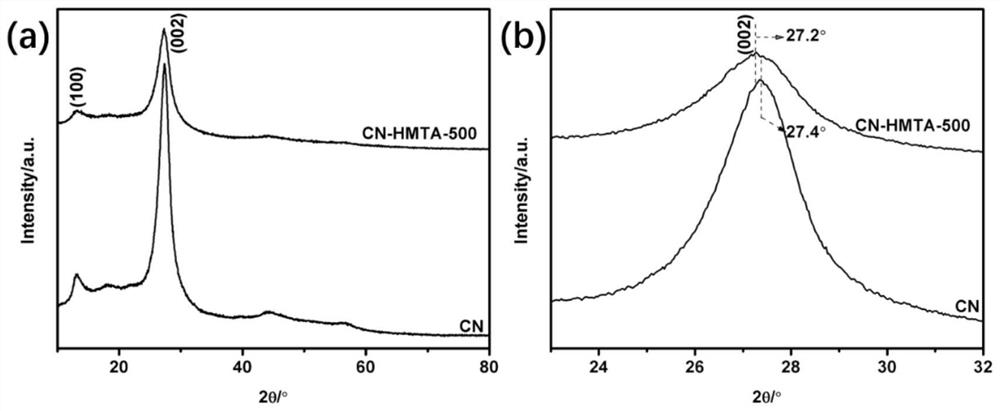

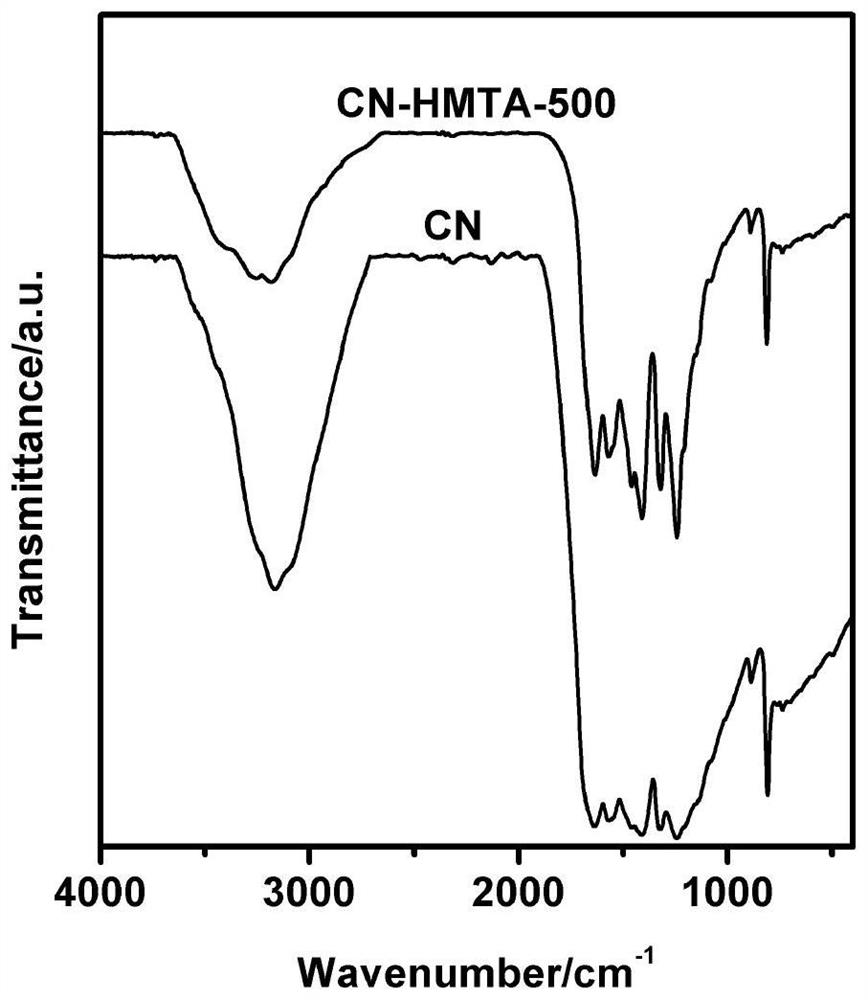

A phase carbon nitride light and sewage treatment technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, light water/sewage treatment, etc. Melamine reaction, small specific surface area of g-C3N4, etc., to achieve excellent photocatalytic activity, enhanced photocurrent response, and time-saving preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention discloses a novel preparation method of a graphitic carbon nitride photocatalyst for sewage treatment, comprising the following steps: in a closed environment, hydrothermally reacting melamine and hexamethylenetetramine to obtain a modified precursor; The modified precursor is calcined at high temperature to obtain modified graphitic carbon nitride.

[0031] Specifically, the procedure is: the mass ratio of melamine to hexamethylenetetramine is 4200: (50-1000), that is, the mass of melamine is a fixed value of 4200mg, and the mass of hexamethylenetetramine is 50-1000mg The dispersant is water. The hydrothermal reaction of the present invention includes: raising the temperature to 160-200° C. and maintaining the temperature for 16-24 hours. In the high temperature calcination reaction of the modified precursor, the mass of the precursor is 1-3 g, and the temperature control program is set as: the temperature is raised to 500-600° C. within 80-120 min, and ...

Embodiment 1

[0034] This embodiment provides a graphite phase carbon nitride photocatalyst for sewage treatment, and the mass ratio of melamine to hexamethylenetetramine is 4200:50.

[0035] The present embodiment provides a preparation method of a graphitic carbon nitride photocatalyst for sewage treatment, comprising:

[0036] Step 1. Take 4.2g of melamine and 50mg of hexamethylenetetramine (HMTA), add them to 30mL of aqueous solution under stirring, and stir for 15 minutes;

[0037] Step 2, placing the dispersion system described in step 1 in a hydrothermal reactor and sealing;

[0038] Step 3, put the hydrothermal reactor described in step 2 into the heating device, then heat up to 180°C and keep for 20h;

[0039] Step 4. The system after the reaction in step 3 is water-cooled, centrifuged, washed, and dried to obtain the processed melamine M-HT-HMTA-0; in M-HT-HMTA-x, x represents the amount of HMTA input (mg) ;

[0040] Step 5, after the precursor obtained in step 4 is ground, 2g is...

Embodiment 2

[0044] This example is the same as Example 1, with the difference that the amount of HMTA input in step 1 is 200 mg to obtain the modified precursor M-HT-HMTA-200 and the graphitic carbon nitride photocatalyst CN-HT -HMTA-200.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com