Titanium alloy hardening and tempering method

A titanium alloy, quenched and tempered technology, to achieve the effect of broadening the application environment, increasing the utilization rate, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

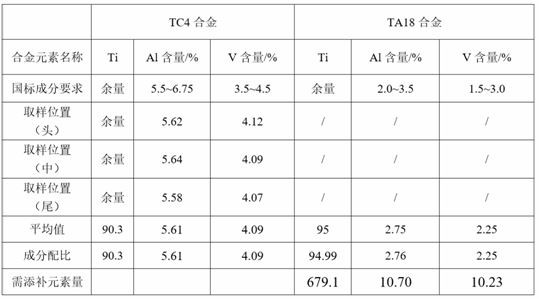

Image

Examples

Embodiment 1

[0018] (5) After the charging is completed, apply a voltage of 32V and move the electrode rod down. When the electrode rod is in contact with the furnace material in the crucible of the solidification furnace and generates current, gradually increase the current. When the current is loaded to 10000A. Keep the current constant by moving the electrode down. After the material in the crucible is completely melted, keep the current for 10 minutes, so that the material in the crucible is fully melted, and the impurities with high density in the crucible have enough time to sink. After sufficient settlement, the molten titanium liquid in the crucible is poured into the round copper crystal with water cooling on the outer wall of the bottom seal through the casting mechanism. After the titanium liquid in the crystallizer is fully cooled, the quality of the original TC4 is changed to low-cost high-quality TA18 alloy quenched and tempered titanium ingot.

[0019] Example 2

[0020] (2...

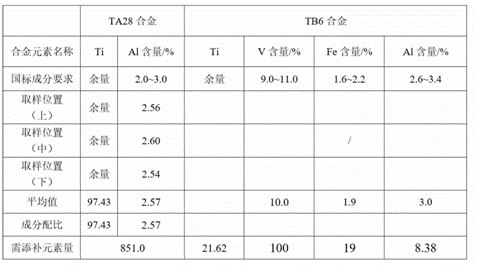

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com