Method for regulating and controlling structure of carbon-supported PtCu3 alloy catalyst

An alloy catalyst, carbon-supported technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as lack of regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of regulation carbon-supported PtCu 3 The method of alloy catalyst structure, the concrete steps are as follows:

[0027] (1) Add Pt / C powder to Cu(NO 3 ) 2 Mix evenly in the aqueous solution, ultrasonic immersion for 30min to obtain a mixed solution; Pt accounts for 20wt.% in the Pt / C powder, C is single-layer graphene, Cu(NO 3 ) 2 The concentration of the aqueous solution is 0.2mol / L, and the Pt and Cu(NO) in the Pt / C powder 3 ) 2 The molar ratio of Cu in is 1:3;

[0028] (2) using liquid nitrogen to freeze the mixed solution obtained in step (1) for 72h to obtain a mixed solid; wherein the air pressure of the freezing treatment is 27MPa, and the temperature is -43°C;

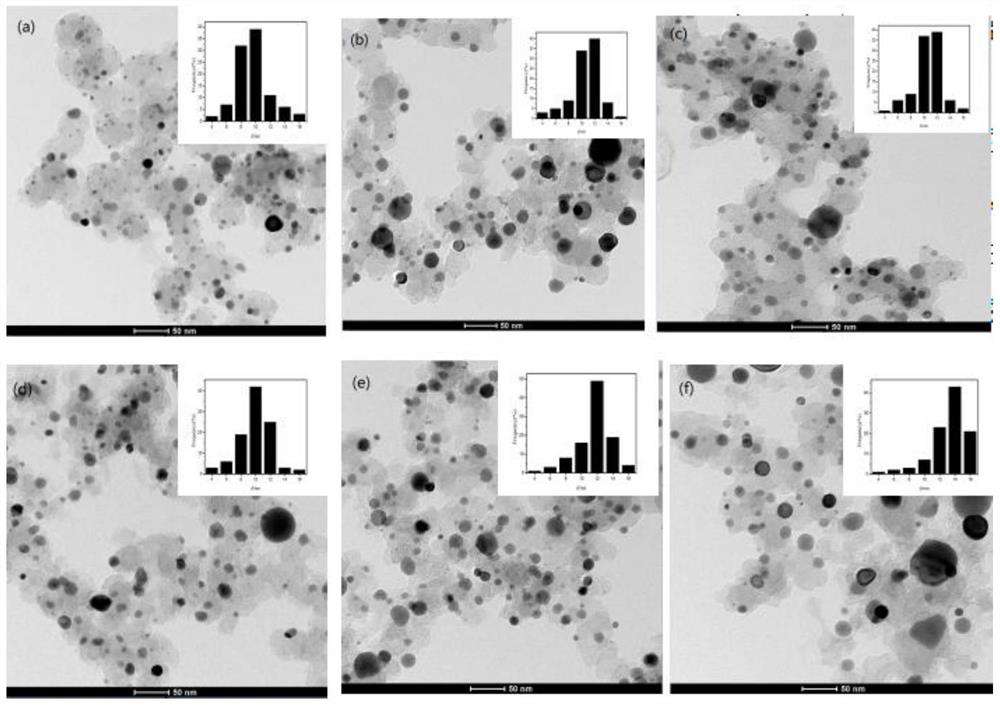

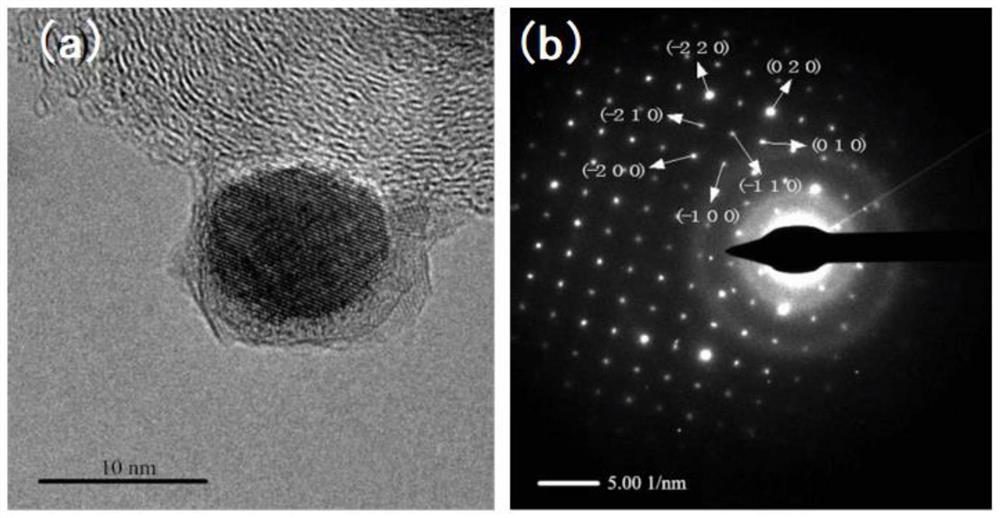

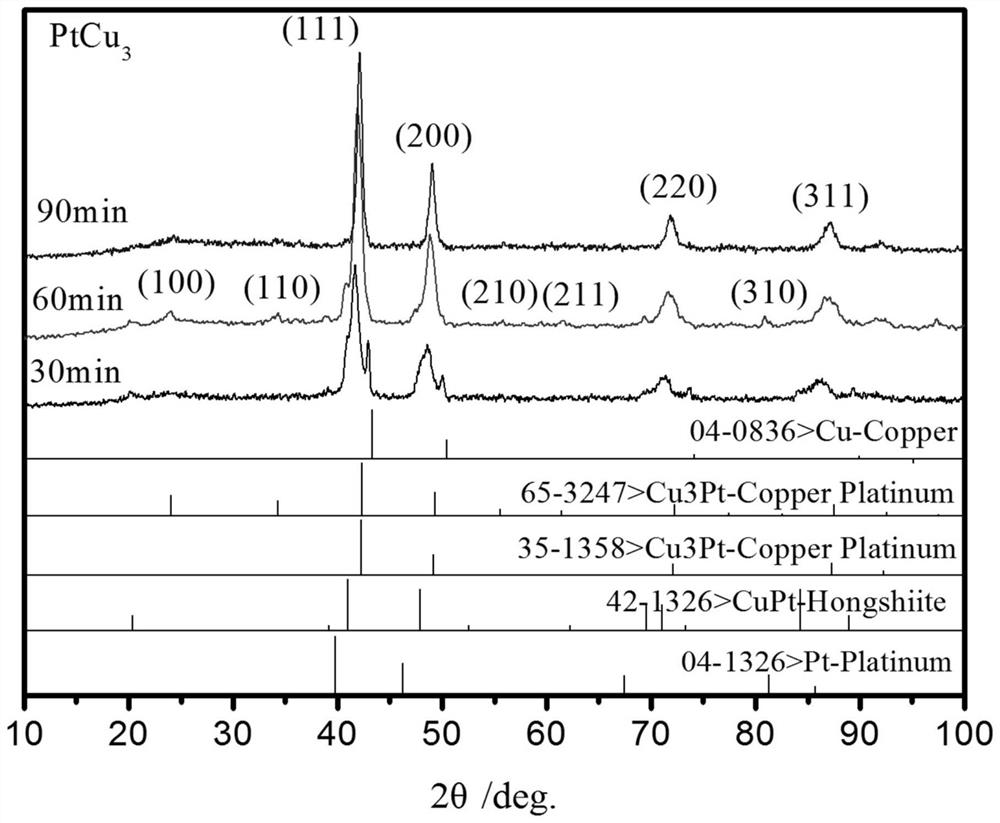

[0029] (3) the mixed solid obtained in step (2) is placed in N 2 The temperature was uniformly heated to 800 °C in the air and heat treated at a constant temperature for 30 min, 60 min and 90 min respectively. 2 Cooled to room temperature in air to obtain PtCu on carbon 3 ...

Embodiment 2

[0032] Embodiment 2: a kind of regulation carbon-supported PtCu 3 The method of alloy catalyst structure, the concrete steps are as follows:

[0033] (1) Add Pt / C powder to CuCl 2 Mix evenly in the aqueous solution, ultrasonic immersion for 40min to obtain a mixed solution; in which Pt accounts for 20wt.% in the Pt / C powder, C is a multi-walled carbon nanotube with a diameter of 5-100nm, CuCl 2 The concentration of the aqueous solution is 0.2mol / L, and the Pt and CuCl in the Pt / C powder 2 The molar ratio of Cu in is 1:3;

[0034] (2) The mixed solution obtained in step (1) is subjected to freezing treatment for 72h to obtain a mixed solid; wherein the air pressure of the freezing treatment is 30MPa, and the temperature is -40°C;

[0035] (3) the mixed solid obtained in step (2) is placed in N 2 The temperature was increased to 800 °C at a constant rate in the air and heat treated at a constant temperature for 60 min. 2 Cooled to room temperature in air to obtain PtCu on c...

Embodiment 3

[0037] Embodiment 3: a kind of regulation carbon-supported PtCu 3 The method of alloy catalyst structure, the concrete steps are as follows:

[0038] (1) Add Pt / C powder to CuCl 2 The aqueous solution was mixed uniformly, and the mixed solution was obtained by ultrasonic immersion for 60min; in which Pt accounted for 20wt.% in the Pt / C powder, C was nanoporous carbon, and CuCl 2 The concentration of the aqueous solution is 0.2mol / L, and the Pt and CuCl in the Pt / C powder 2 The molar ratio of Cu in is 1:3;

[0039] (2) freezing the mixed solution obtained in step (1) for 75h to obtain a mixed solid; wherein the air pressure of the freezing treatment is 33MPa, and the temperature is -33°C;

[0040] (3) the mixed solid obtained in step (2) is placed in N 2 The temperature was uniformly heated to 800 °C in the air and heat treated at a constant temperature for 30 min, 60 min and 90 min respectively. 2 Cooled to room temperature in air to obtain PtCu on carbon 3 alloy catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com